GIP driving circuit of low-power-consumption display screen and control method of GIP driving circuit

A technology of drive circuit and control method, which is applied in static indicators, instruments, etc., can solve the problems of high power consumption and reduced battery life, and achieve the effects of reducing power consumption, improving battery life and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

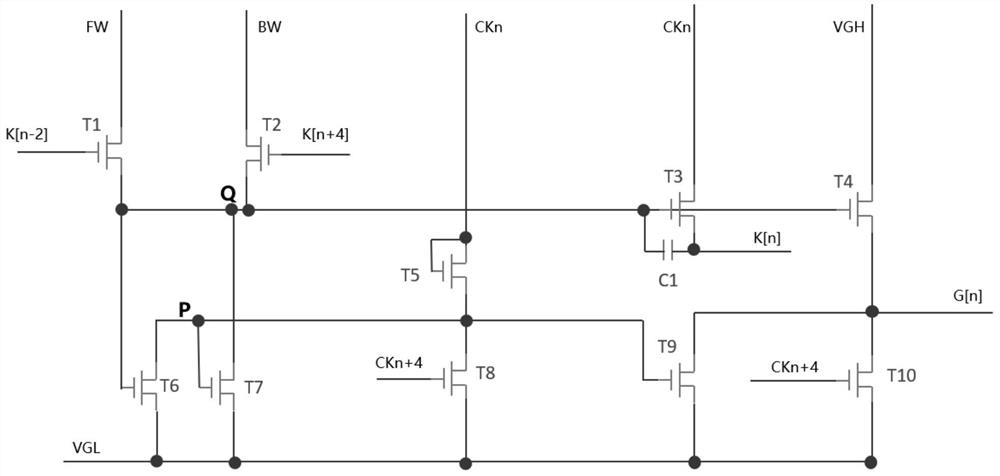

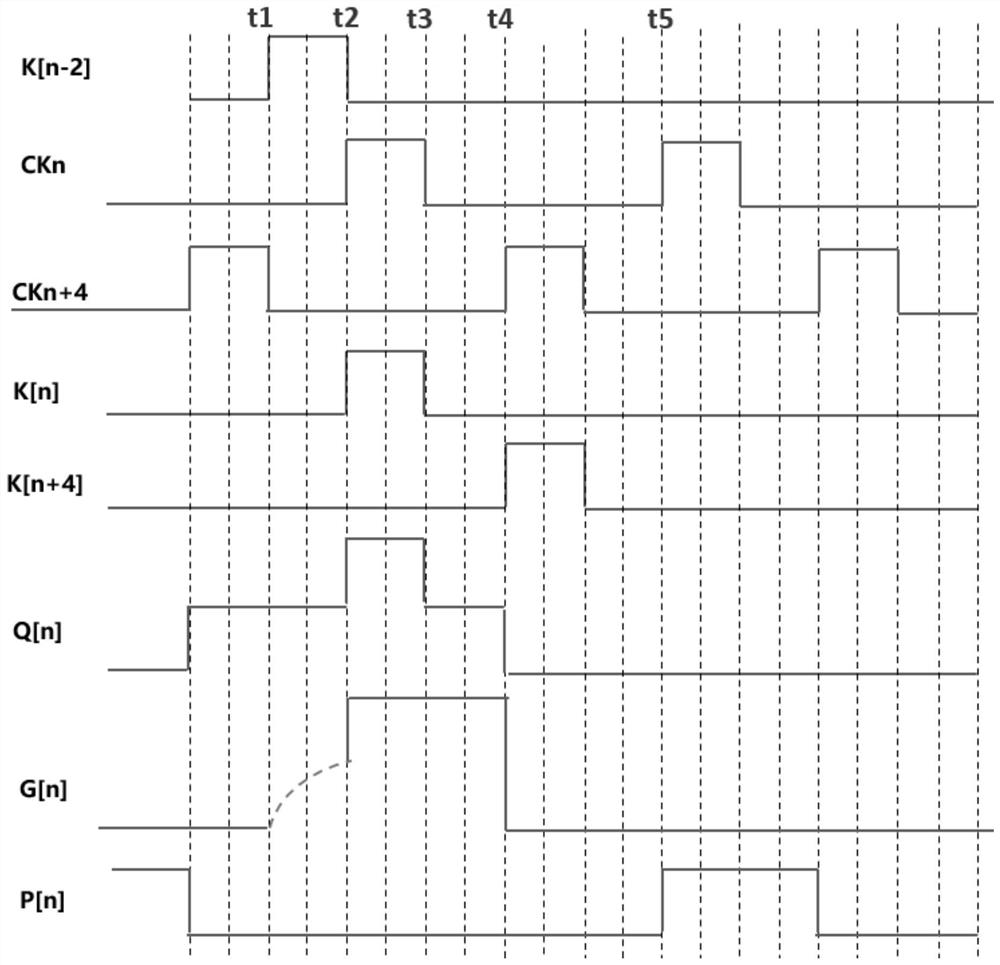

[0039] Please refer to figure 1 and image 3 , Embodiment 1 of the present invention is:

[0040] Please refer to figure 1, a GIP driving circuit of a low-power display screen, comprising a transistor T1, a transistor T2, a transistor T3, a transistor T4, a transistor T5, a transistor T6, a transistor T7, a transistor T8, a transistor T9, a transistor T10 and a capacitor C1, the transistor The source of T1 is electrically connected to the gate of transistor T6, the drain of transistor T7, the source of transistor T2, the gate of transistor T3 and one end of capacitor C1 respectively, and the drain of said transistor T6 is respectively connected to the gate of transistor T7. Pole, the drain of transistor T8, the source of transistor T5 and the gate of transistor T9 are electrically connected, and the drain of transistor T9 is electrically connected with the drain of transistor T10 and the source of transistor T4 respectively and the drain of transistor T9 1. The drain of the...

Embodiment 2

[0053] Please refer to Figure 1 to Figure 3 , the second embodiment of the present invention is:

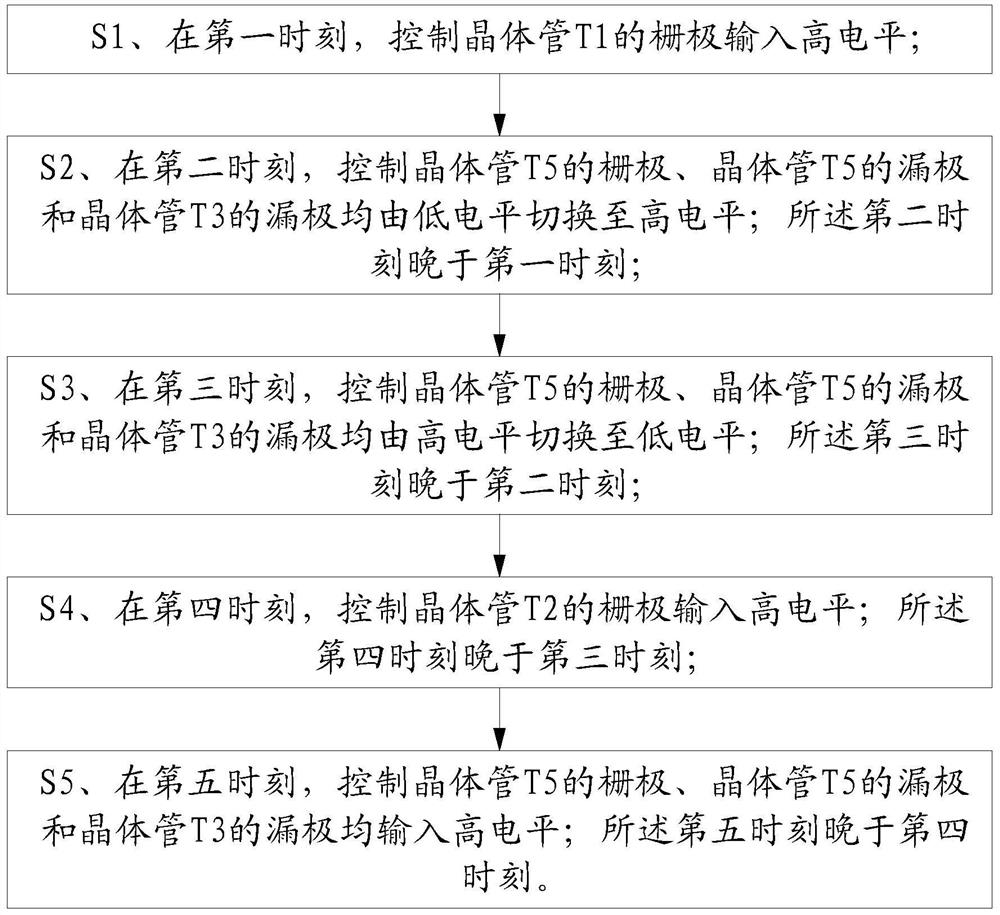

[0054] Please refer to figure 2 , a control method for a GIP drive circuit of a low-power display screen, comprising the following steps:

[0055] S1. At the first moment, control the gate of the transistor T1 to input a high level;

[0056] S2. At a second moment, control the gate of the transistor T5, the drain of the transistor T5, and the drain of the transistor T3 to switch from a low level to a high level; the second moment is later than the first moment;

[0057] S3. At a third moment, control the gate of the transistor T5, the drain of the transistor T5, and the drain of the transistor T3 to switch from a high level to a low level; the third moment is later than the second moment;

[0058] S4. At the fourth moment, the gate of the control transistor T2 inputs a high level; the fourth moment is later than the third moment;

[0059] S5. At a fifth moment, control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com