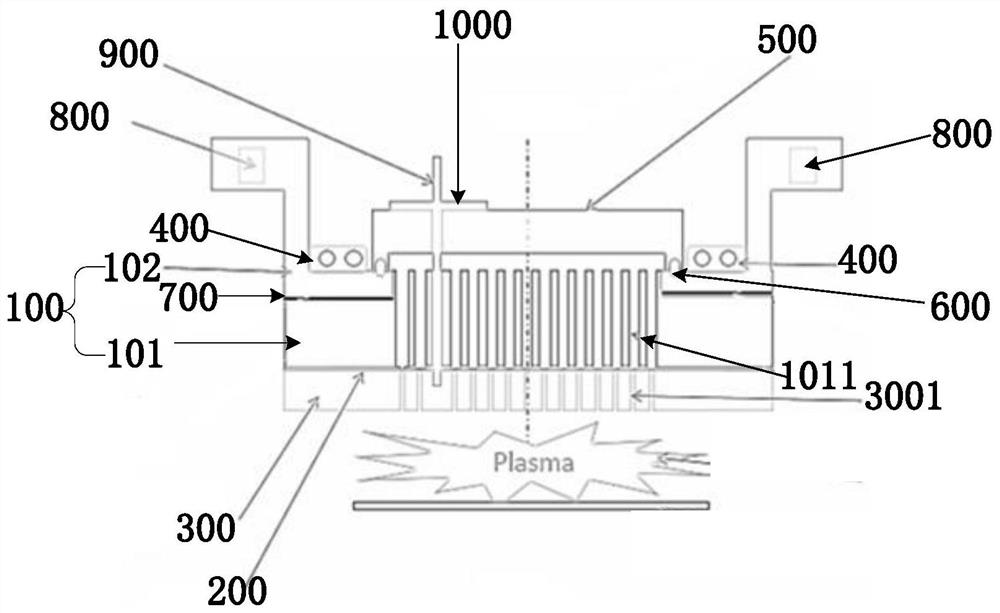

Top electrode assembly and plasma processing equipment

An electrode assembly and a main body technology are applied in the field of plasma treatment equipment, which can solve the problems of low heat conduction efficiency between a mounting substrate and a gas shower head, and achieve the effect of improving heat conduction and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Next, the technical scheme in the present application embodiment will be described in the present application, and it is understood that the described embodiments are intended to be described herein, not all of the embodiments of the present application. Based on the embodiments in the present application, all other embodiments obtained by those of ordinary skill in the art without making creative labor premises, all of the present application protected.

[0036]There are many specific details in the following description to facilitate the apparatus, but the present application can also employ other other ways unlike otherwise described herein, those skilled in the art can do without violating the contents of this application. Similarly, the present application is not limited by the specific embodiments disclosed in the following.

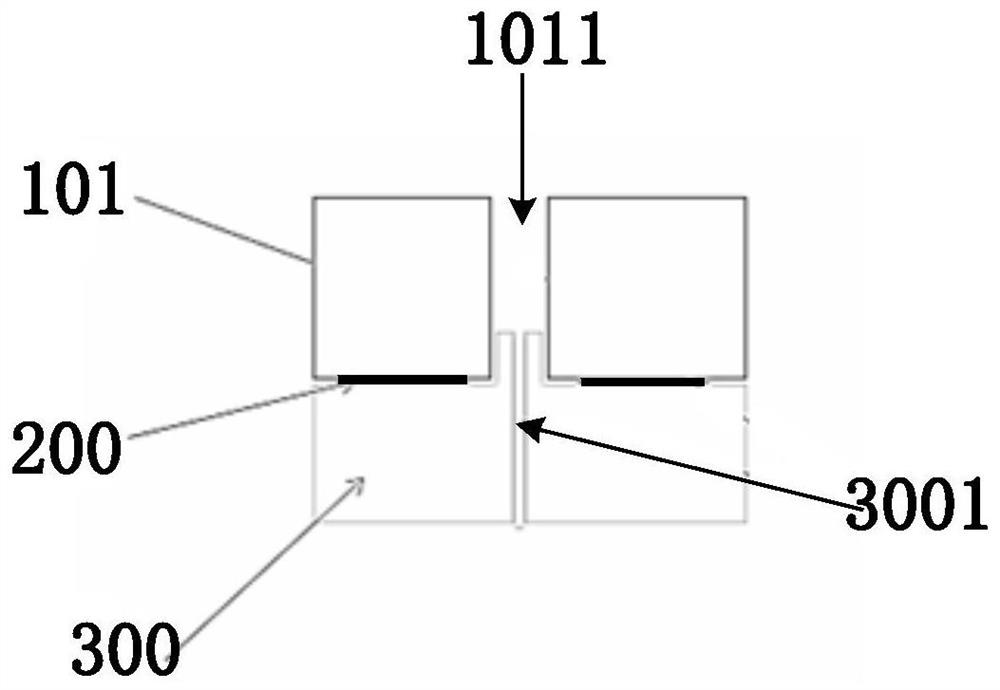

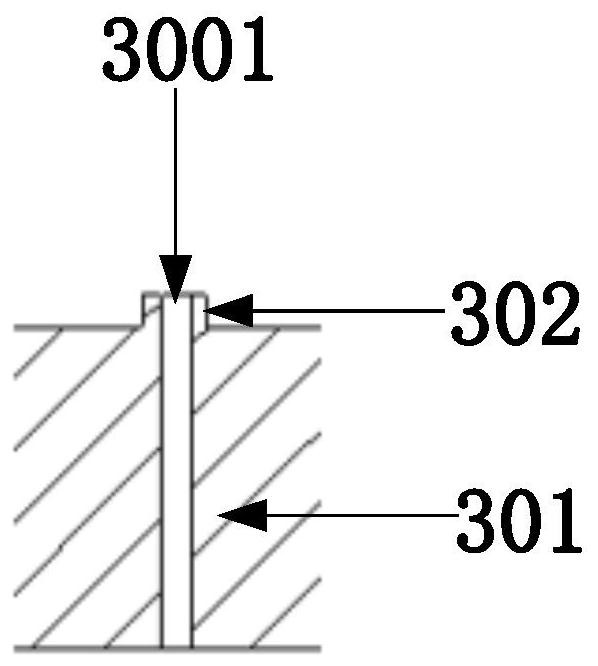

[0037]As in the context of the background, the heat conduction efficiency of the mounting substrate and the gas shower head is low in the process of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com