Heat-conducting toughened flame-retardant reinforced PS plastic and preparation method thereof

A toughening and plastic technology, which is applied in the field of heat conduction toughened and flame retardant reinforced PS plastic and its preparation, can solve the problems of poor heat conduction effect, high brittleness, and reduced practicability, so as to improve heat conduction effect, reduce brittleness, and improve phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

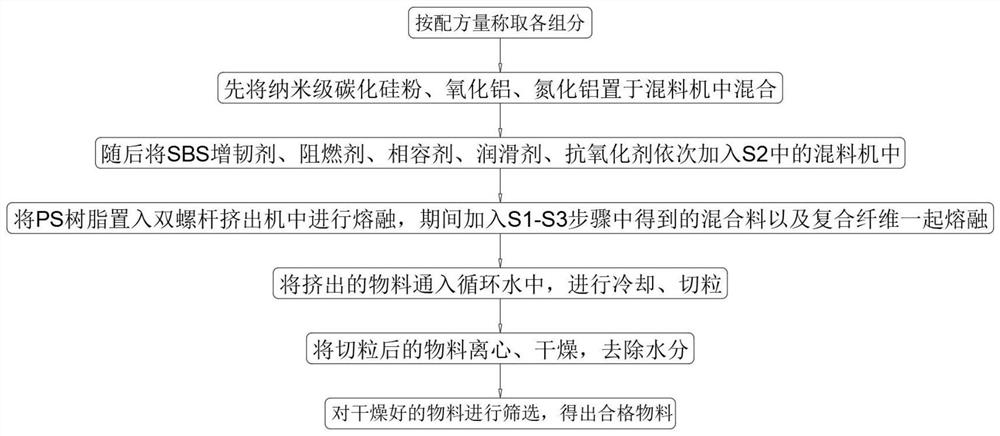

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

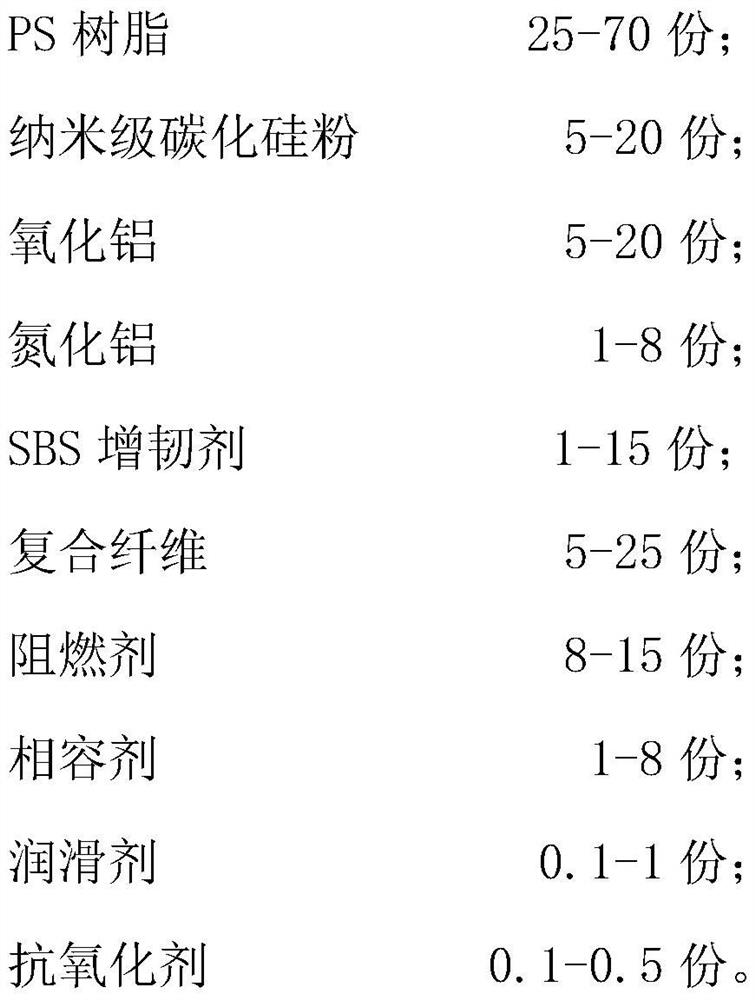

[0029] see figure 1 , an embodiment provided by the present invention: a thermally conductive, toughened and flame-retardant reinforced PS plastic, in parts by mass, comprising the following components:

[0030]

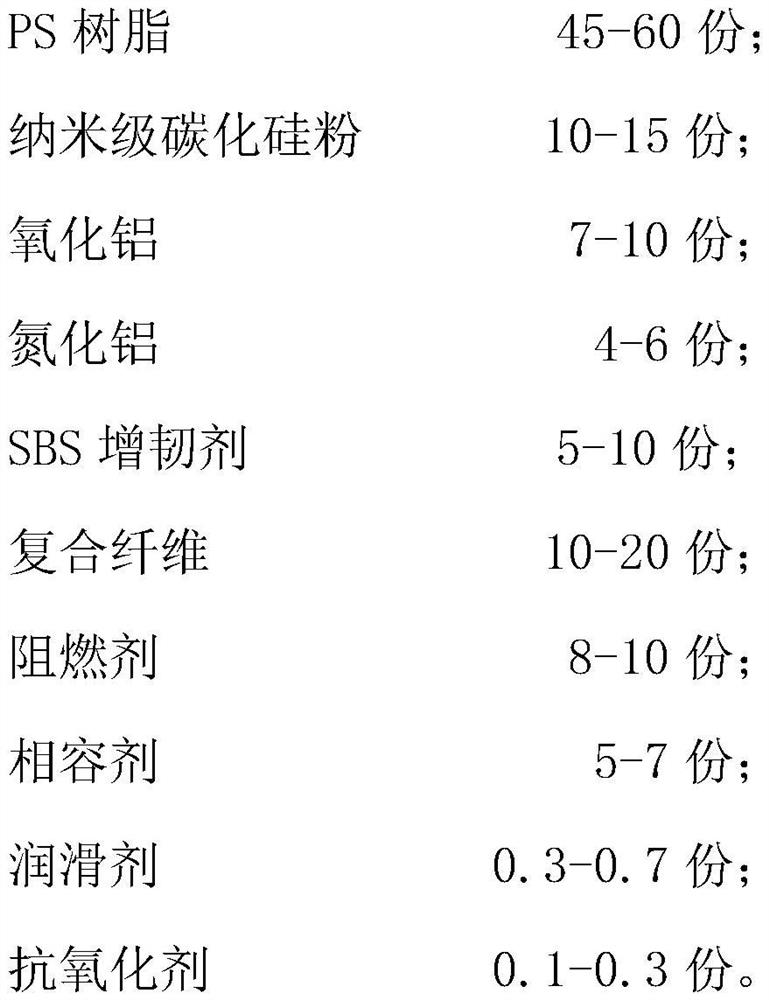

[0031] Further, the thermally conductive, toughened and flame-retardant reinforced PS plastic specifically includes the following components:

[0032]

[0033]

[0034] By mixing nano-scale silicon carbide powder, alumina, aluminum nitride, SBS toughener, composite fiber, flame retardant, compatibilizer, lubricant and antioxidant through PS resin to generate new PS plastics, nano-scale silicon carbide powder, Alumina and aluminum nitride are therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com