A bidirectional radiation co-rotation dual circularly polarized antenna based on 3D printing technology

A 3D printing, bidirectional radiation technology, applied in the field of antennas, can solve the problems of complex antenna structure, narrow axial ratio bandwidth, low gain, etc., and achieve the effects of stable radiation performance, wide axial ratio bandwidth and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

[0024] In this embodiment, combined with 3D printing technology, a bidirectional radiation co-rotational dual circularly polarized antenna based on 3D printing technology is proposed. The entire antenna is integrally formed by 3D printing dielectric materials and electroplating thin metal layers. In this embodiment, the relative permittivity of the dielectric material is 2.9, and the loss tangent is 0.01. In specific applications, dielectric materials with other parameters can be used according to actual conditions.

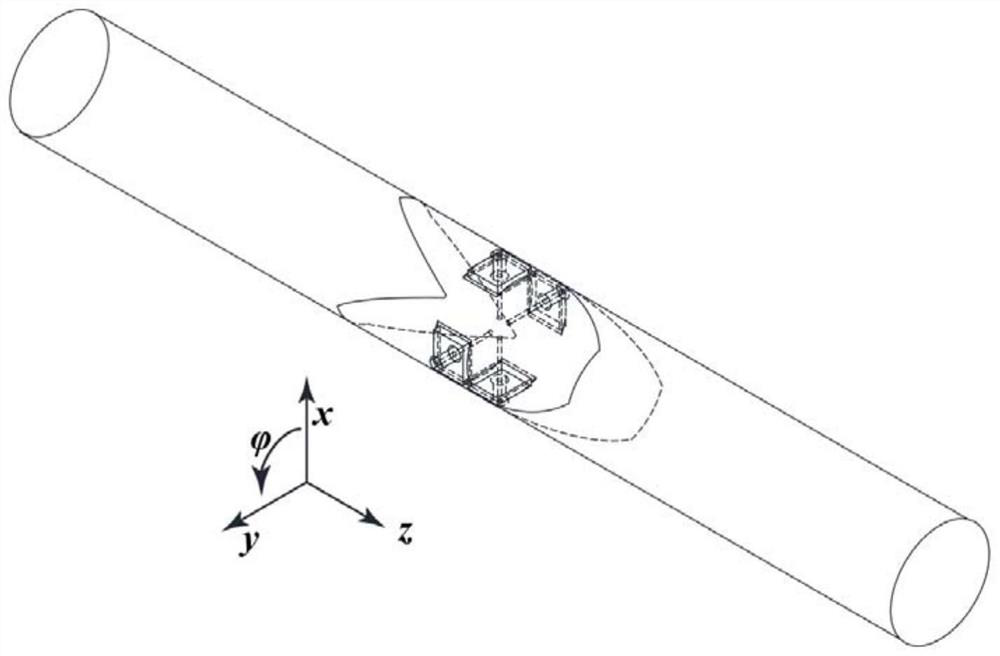

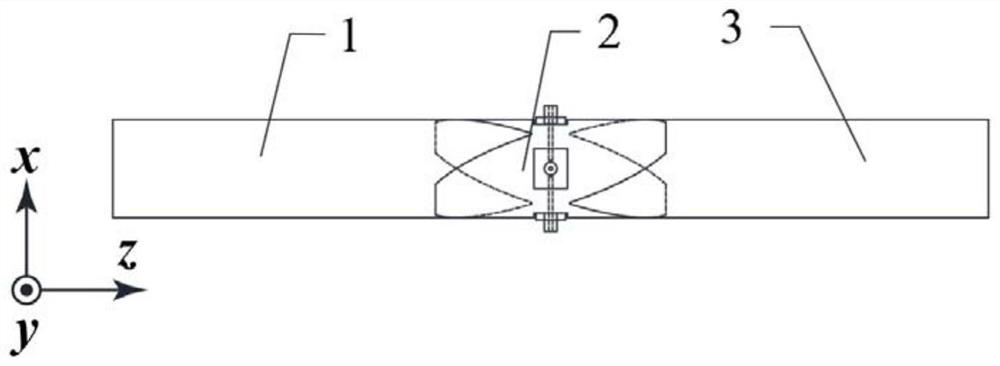

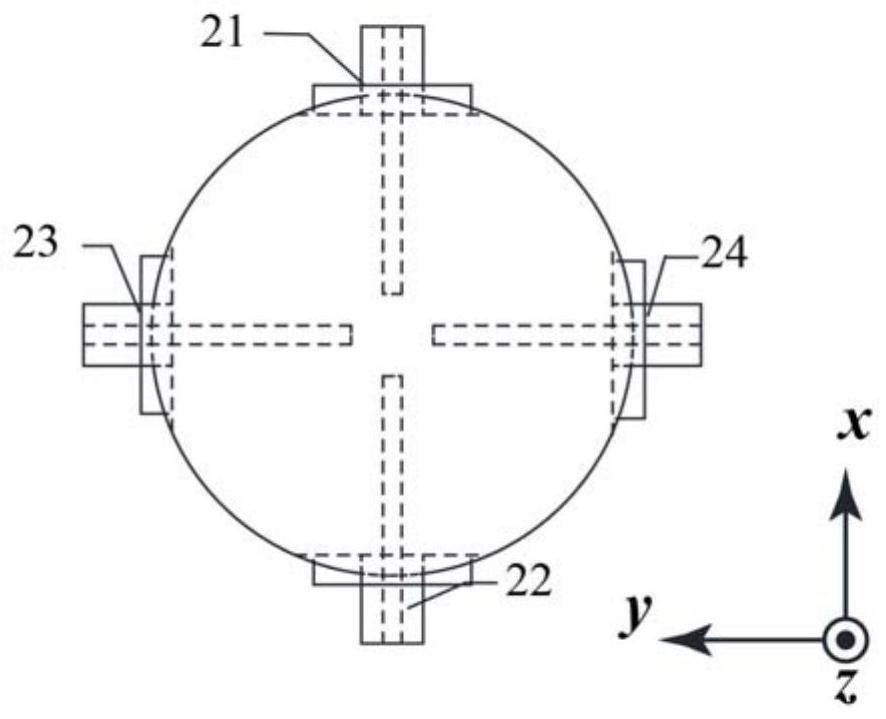

[0025] Antenna structure such as figure 1 and figure 2 As shown, the antenna includes a circular waveguide 2, and a first dielectric rod 1 and a second dielectric rod 3 respectively located on both sides of the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com