Testing method for testing a cable for leak-tightness, and leak-tightness testing device for carrying out the method

A technology of inspection device and inspection method, which is applied in the direction of fluid tightness test, liquid tightness measurement using liquid/vacuum degree, measuring device, etc., and can solve problems such as pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

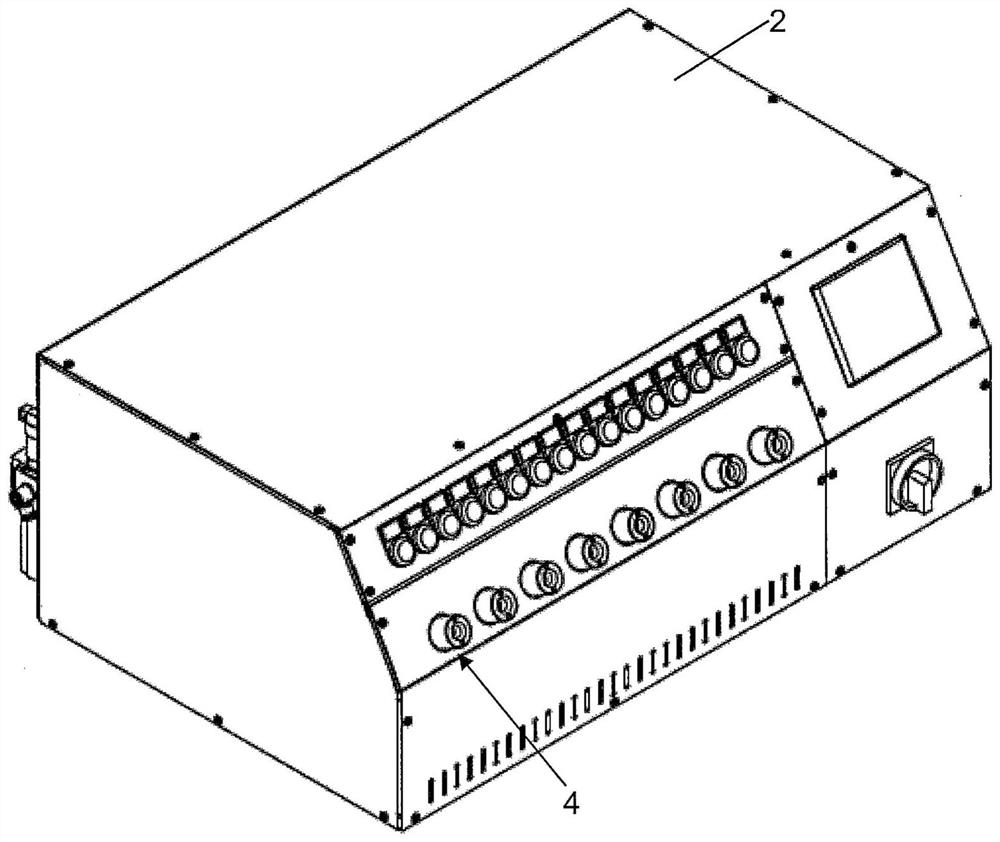

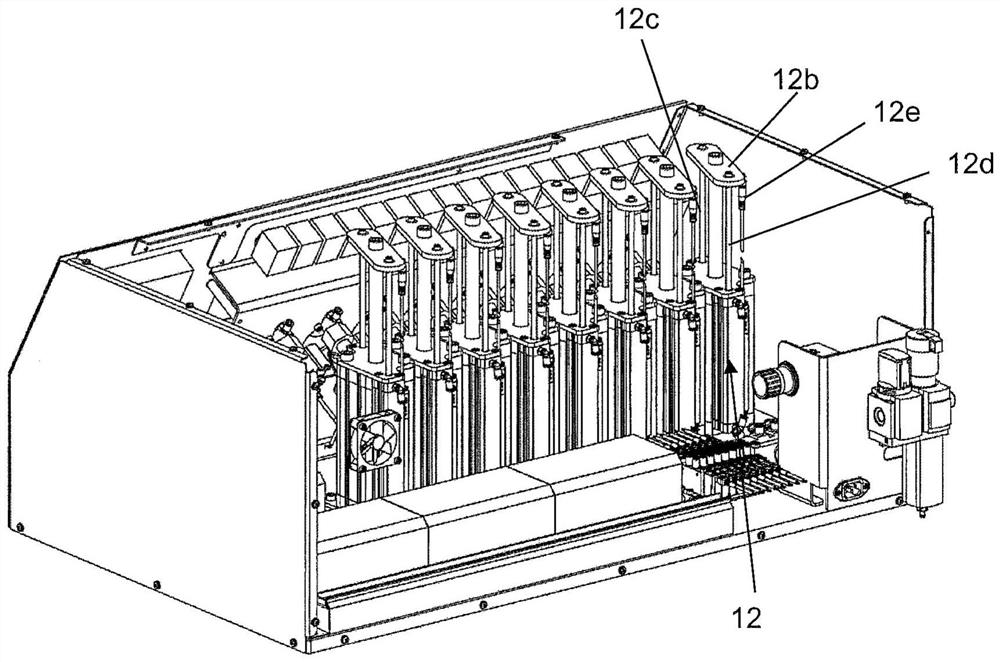

[0166] figure 1 An isometric front view of a leak-tightness testing device according to the invention, here comprising eight measuring cells, is shown.

[0167] Accordingly, the leak-tightness testing device has a surrounding, box-like housing 2 , which delimits an interior space in which a plurality of measuring units and other instruments are arranged.

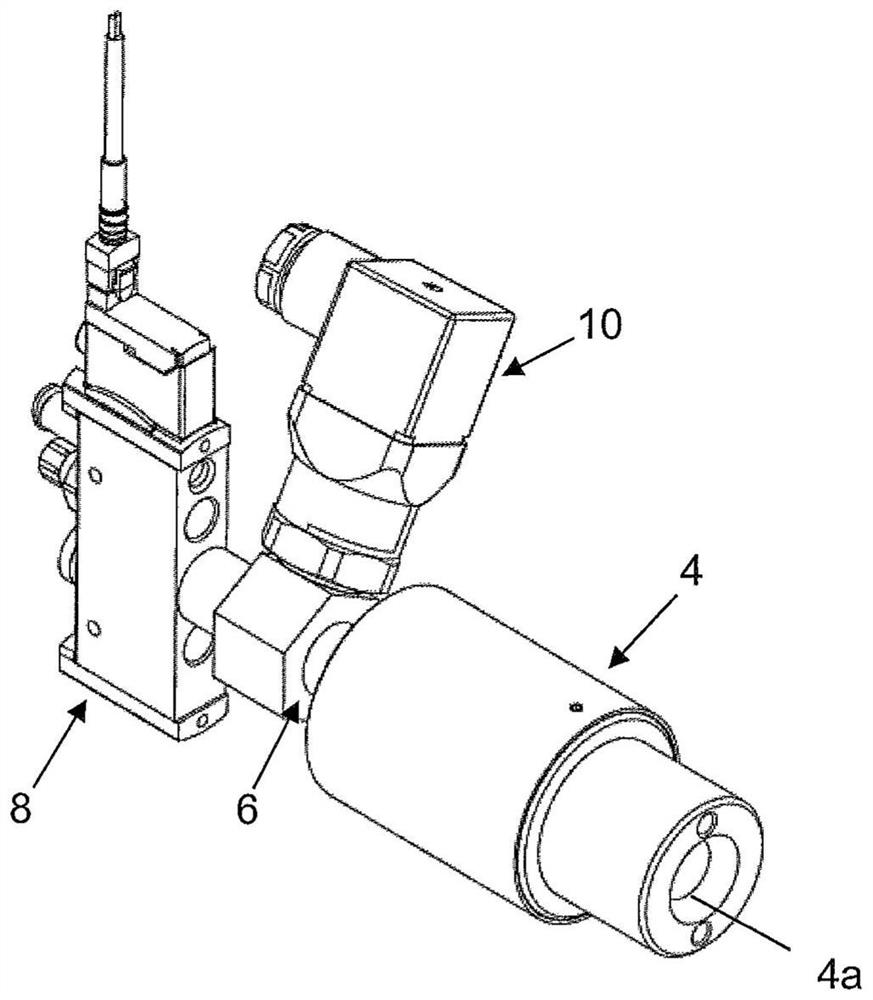

[0168] Each measuring unit comprises a substantially hollow-cylindrical adapter 4 which, in the mounted state, protrudes with its insertion opening 4a, which is open to the front, from a corresponding opening in the housing 2, so that the test body or test piece can be The open test end is inserted into said insertion opening 4a. Each adapter 4 is connected to a valve 8 via a line piece 6 arranged at the rear end of the adapter 4 . Furthermore, connected to the line part 6 is a pressure sensor 10 which detects the line pressure and the system pressure in the line and test body. Finally, the valve is connected to a piston ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap