Ore pass dust treatment device

A technology for dust treatment and sliding mines, which is applied in the direction of combined devices, separation of dispersed particles, chemical instruments and methods, etc. It can solve the problems of inefficient dust treatment, affecting the normal operation of staff, and excessive dust in shafts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

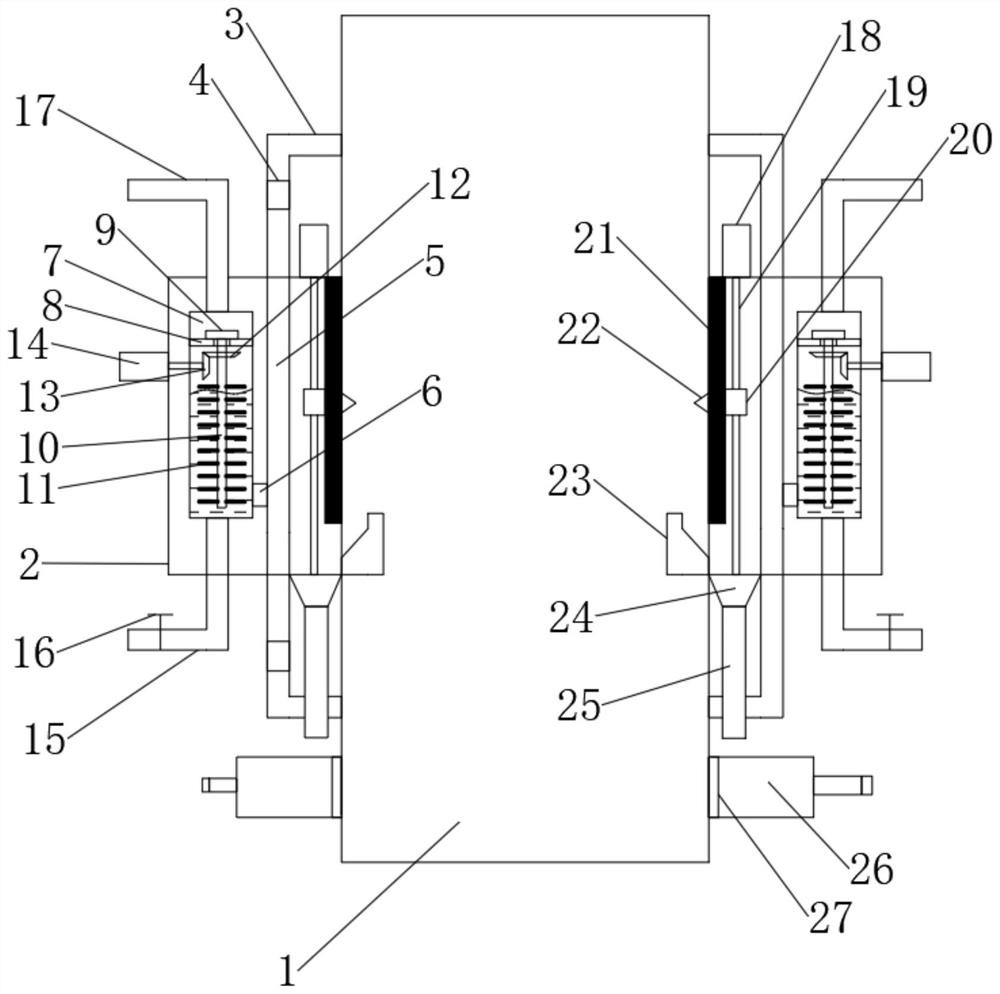

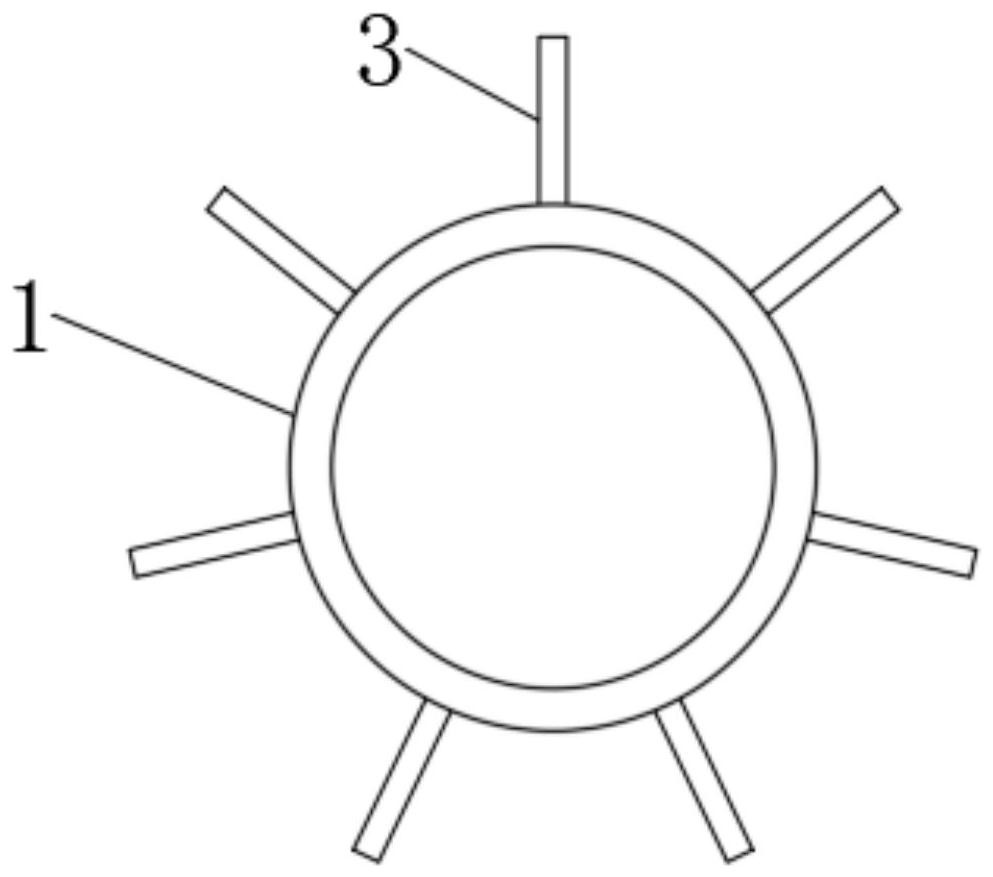

[0026]Such asFigure 1-4As shown, a slip dust treatment apparatus includes a mounting tank 2 mounted on the side of the mine 1, and the upper side of the mounting tank 2 is provided with a suction tube 3, and the upper straw 3 is evenly distributed around the outer periphery of the mine 1. The suction pump 4 is provided in the upper suction tube 3, and the upper strip 3 is connected to the air tube 5, the air pipe 5 is connected to the joint pipe 6, and the engaging tube 6 is connected to the filter cartridge 7, the filter cartridge The cleaning liquid is provided, and the filter cartridge 7 is provided with a stirring device, and the bottom of the filter cartridge 7 is provided with a drain pipe 15, and a valve 16 is provided on the drain pipe 15, the upper side of the filter cartridge 7. An air intake pipe 17 is provided, and the mounting tank 2 is provided with an electrostatic adsorption plate 21 between 1, and the electrostatic adsorption plate 21 is provided with a scraper blad...

Embodiment 2

[0039]The present embodiment is a further improvement and definition of Example 1 on the basis of Example 1.

[0040]A slip dust treatment apparatus, including all components in Example 1, further comprising:

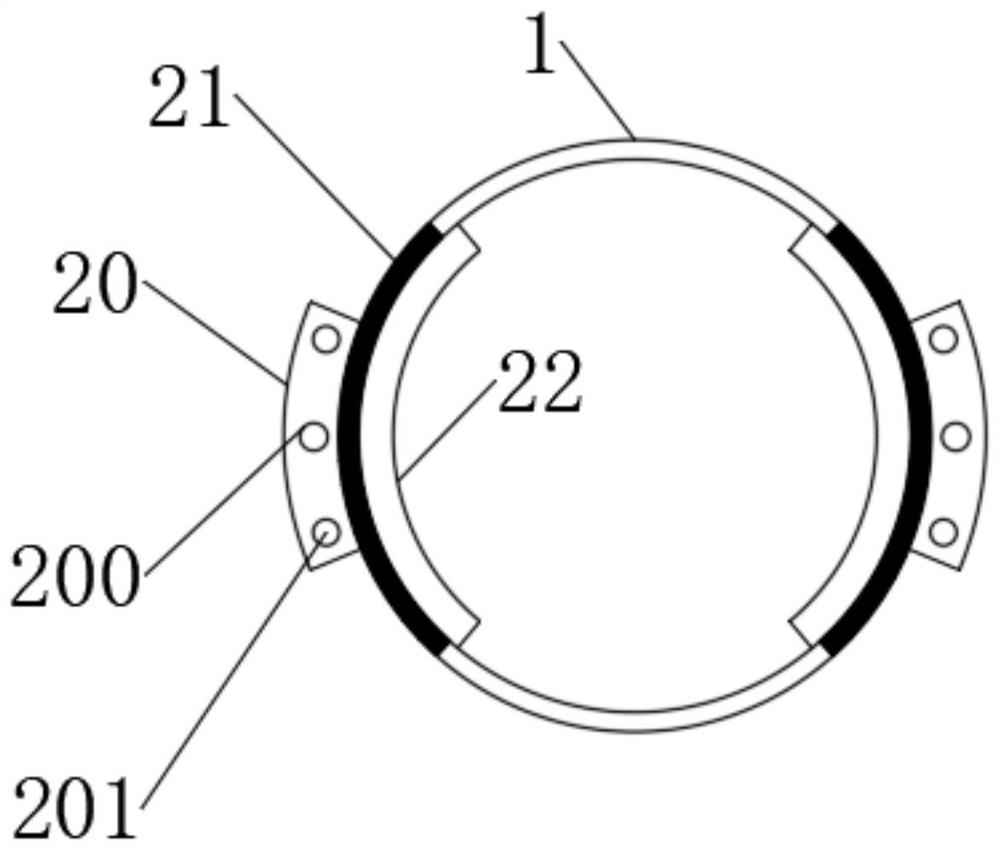

[0041]Further, the lifting device includes a second motor 18 that is fixed to the mounting tank 2, the second motor 18 is connected to the threaded rod 19, and the intermediate position of the rumor block 20 is provided with a threaded hole. 200, the threaded hole 200 is threaded with the threaded rod 19, and a light pore 201 is provided on the lift block 20, which is provided with a slip post, and the spool is fixed to the mounting box 2.

[0042]Specifically, by setting the second motor 18 and the threaded rod 19, the lifting control of the lifting block 20 is realized, so that the upper and lower moving movement of the electrostatic adsorption plate 21 is moved, and the dust removal operation is performed.

[0043]Further, two light pores 201 are provided.

[0044]Specifically, in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com