Cotton feeding machine for fire prevention and plastic film removal

A cotton feeding machine and mulching technology, applied in fiber feeding, fiber opening and cleaning machines, textiles and papermaking, etc., can solve problems such as difficult rescue, serious problems, and high risk of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

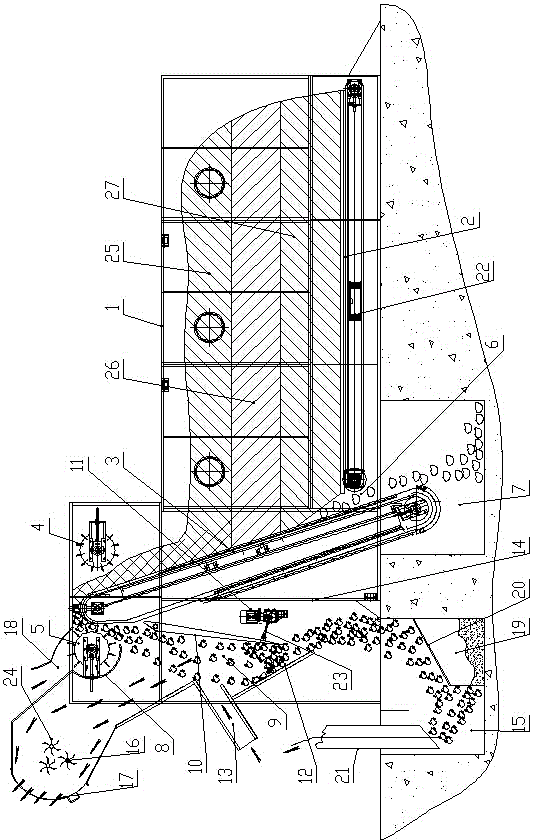

[0022] Such as figure 1 As shown, the fire-proof and film-removing cotton feeding machine of the present invention includes a cotton storage box 1, and a horizontal conveying mechanism 2, a lifting chain 3, a cotton roller 4 and a cotton stripping roller 5 are arranged in the cotton storing box 1, and the horizontal conveying mechanism 2 is set horizontally on the rear side of the bottom of the cotton storage box 1, and the lifting chain 3 is set in front of the horizontal conveying mechanism 2, and the rear of the lifting chain 3 is set with a low front height and an inclined setting, between the front end of the horizontal conveying mechanism 2 and the lower rear side of the lifting chain 3 There is a debris drop gap 6, and a storage pit 7 connected to the debris drop gap 6 is provided under the cotton storage box 1. Cotton leveling roller 4 is set behind the upper end of the lifting chain 3, and cotton stripping roller 5 is set on the lifting chain 3. In front of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com