Composite anode for hydrometallurgy and its preparation method and application

A composite anode and hydrometallurgy technology, applied in the direction of electrodes, electrolytic components, electrolysis process, etc., can solve the problems of lower grade of cathode products, easy to produce a large amount of anode slime, low catalytic activity, etc., and achieve improved cathode current efficiency and anode corrosion The effect of reducing the rate and reducing the overpotential of oxygen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] When the composite anode for hydrometallurgy of the present invention is used as a zinc electrodeposition anode, the working anode is Al / Sn-Ni-Ag / MnO 2 , the oxygen barrier intermediate layer Sn-Ni-Ag ternary alloy, its thickness is 40μm, the electrocatalytic oxygen evolution layer is MnO 2 layer, the anode structure is a flat plate, and the cathode is an aluminum electrode.

[0048] Its Al / Sn-Ni-Ag / MnO 2 The composite anode preparation method is as follows:

[0049] (1) Cut the Al plate into 10mm×10mm×2mm samples by wire cutting method, and use 1200-mesh metallographic sandpaper to polish the surface, and place it in 10% acetone solution to clean the surface of the Al substrate by ultrasonic vibration Take out the oil stains and impurities, wash them with distilled water and ethanol, and set aside.

[0050] (2) The Sn-Ni-Ag coating was prepared on the surface of the Al substrate by electroless plating.

[0051] The bath system is: SnCl (40%), NiCl (30%), AgCl (30%)...

Embodiment 2

[0060] When the composite anode for hydrometallurgy of the present invention is used as a copper electrodeposition anode, the working anode is Fe / Sn / MnO 2 , the oxygen barrier middle layer Sn, its thickness is 42μm, the electrocatalytic oxygen evolution layer is MnO 2 layer, the anode structure is a flat plate, and the cathode is a stainless steel electrode.

[0061] Its Fe / Sn / MnO 2 The composite anode preparation method is as follows:

[0062] (1) Using the wire cutting method, cut the Fe plate into a sample of 10mm×10mm×2mm, and polish the surface with 1200-mesh metallographic sandpaper, and place it in 10% acetone solution with ultrasonic vibration to remove the surface of the Fe substrate Take out the oil stains and impurities, wash them with distilled water and ethanol, and set aside.

[0063] (2) The Sn coating was prepared on the surface of the Fe substrate by electroless plating.

[0064] The plating solution system is: SnCl (30g / L), sodium hypophosphite (4g / L) as ...

Embodiment 3

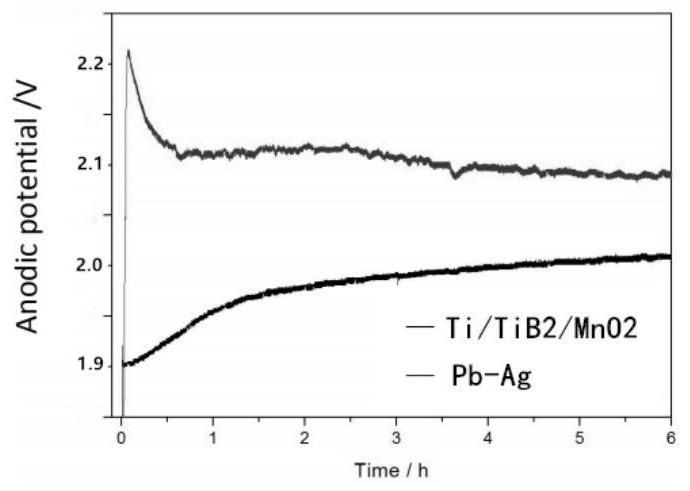

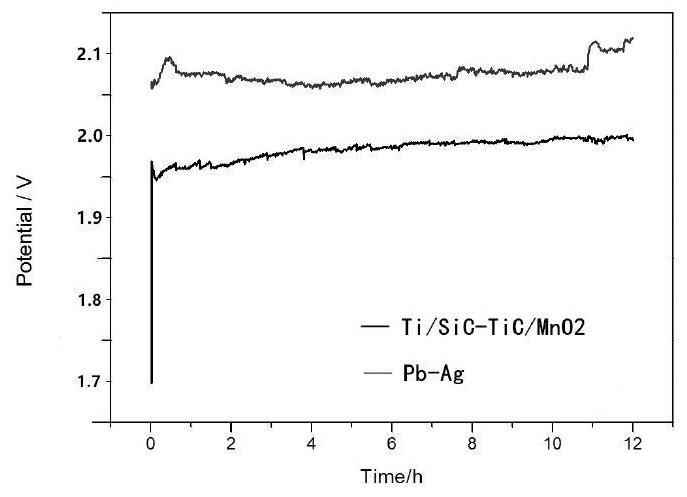

[0073] When the composite anode for hydrometallurgy of the present invention is used as a manganese electrodeposition anode, the working anode is Ti / TiB 2 / MnO 2 , the anode structure is grid-shaped, in which the oxygen barrier layer TiB 2 The thickness is 120μm, and the electrocatalytic oxygen evolution layer is MnO 2 layer, and the cathode is a stainless steel electrode.

[0074] Its Ti / TiB 2 / MnO 2 The composite anode preparation method is as follows:

[0075] (1) Using the method of wire cutting, the Ti plate is cut into a sample of 10mm×10mm×2mm, and the surface is polished with 1200 mesh metallographic sandpaper, and the polished Ti substrate is placed in 5% sodium hydroxide Soak in the solution, and then rub the metal substrate with sandpaper, then place the metal substrate in 10% oxalic acid solution, under boiling, etch for 2 hours, take it out and wash it with distilled water and ethanol for later use.

[0076] (2) Prepare TiB on the surface of Ti substrate by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com