PP plastic recycling treatment system and treatment method

A treatment system and plastic recycling technology, applied in plastic recycling, recycling technology, chemical instruments and methods, etc., can solve problems such as prolonging the working hours of cleaning operations, reducing the cleaning efficiency of plastic bottles, and residual chemical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

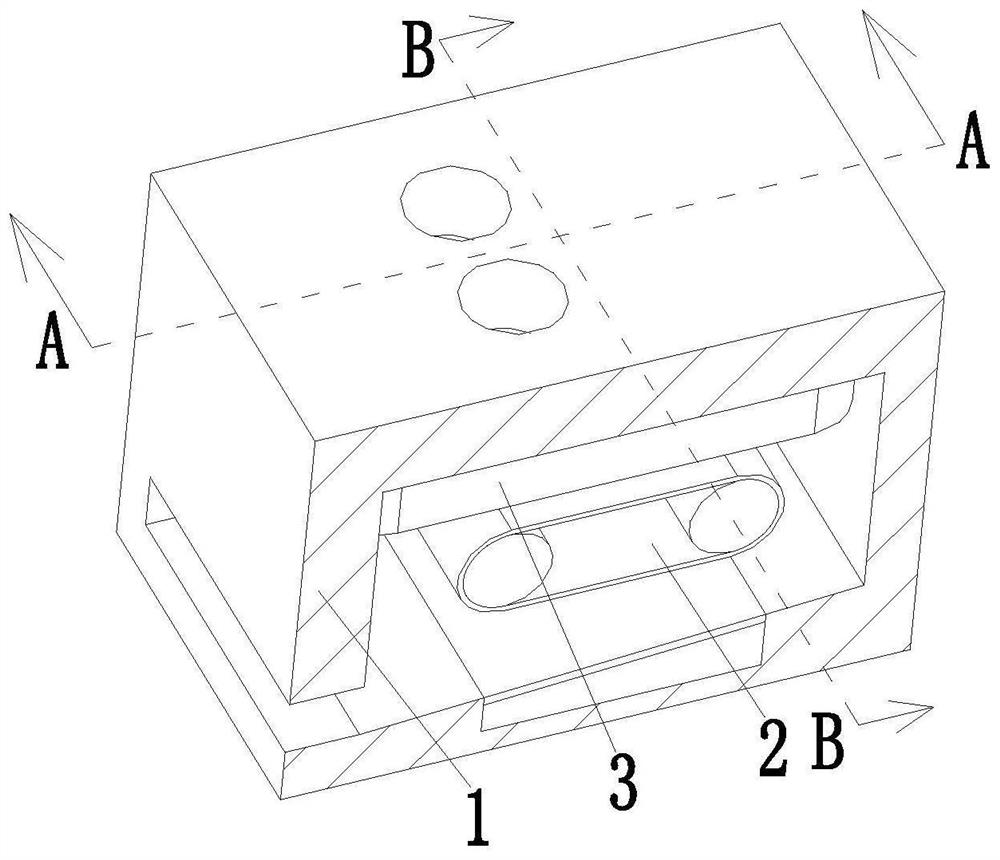

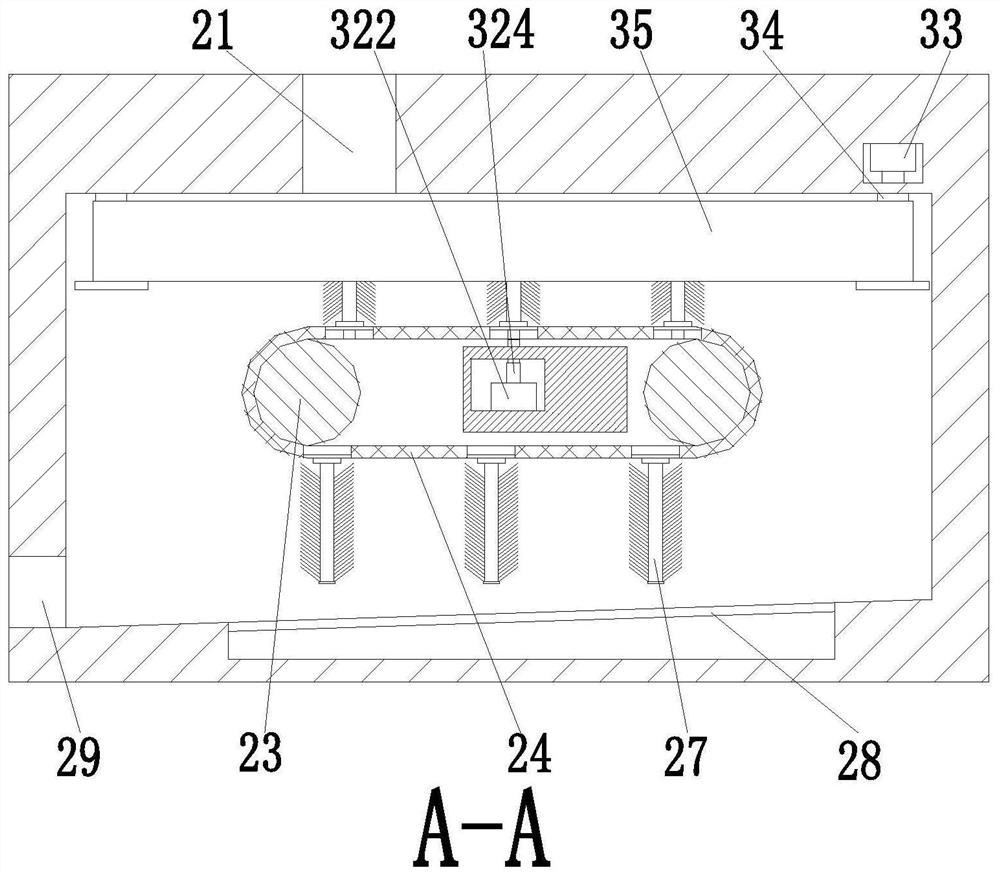

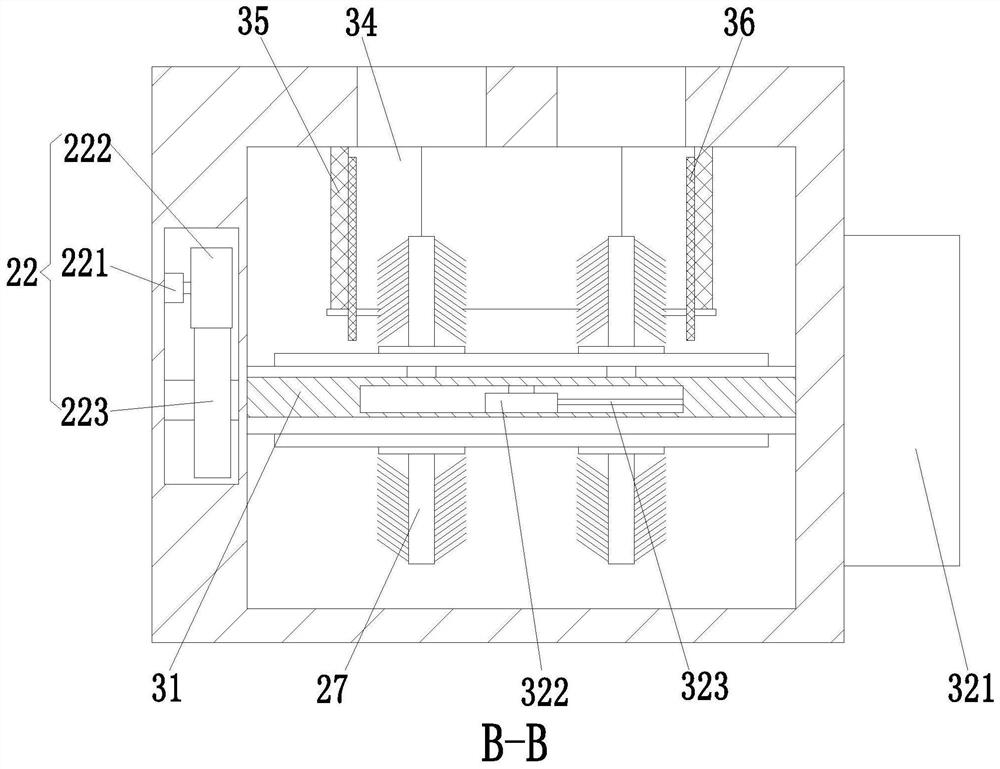

[0030] Such as Figure 1 to Figure 6 As shown, a PP plastic recovery and reuse processing system includes a base frame 1, a feeding and conveying device 2, and an internal and external cleaning device 3. A feeding and conveying device 2 is arranged between the inner walls of the front and rear ends of the base frame 1, and the base The internal and external cleaning device 3 is arranged on the inner wall of the upper end of the frame 1; the lower end surface of the base frame 1 is inclined from the bottom to the right from left to right.

[0031] The feeding and conveying device 2 guides the plastic bottle from the feeding position to the cleaning position. After the inner and outer cleaning device 3 finishes cleaning the plastic bottle, the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com