Sewing equipment for silicon steel normalization

A technology for suturing equipment and steel strips, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as easy fracture of silicon steel sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

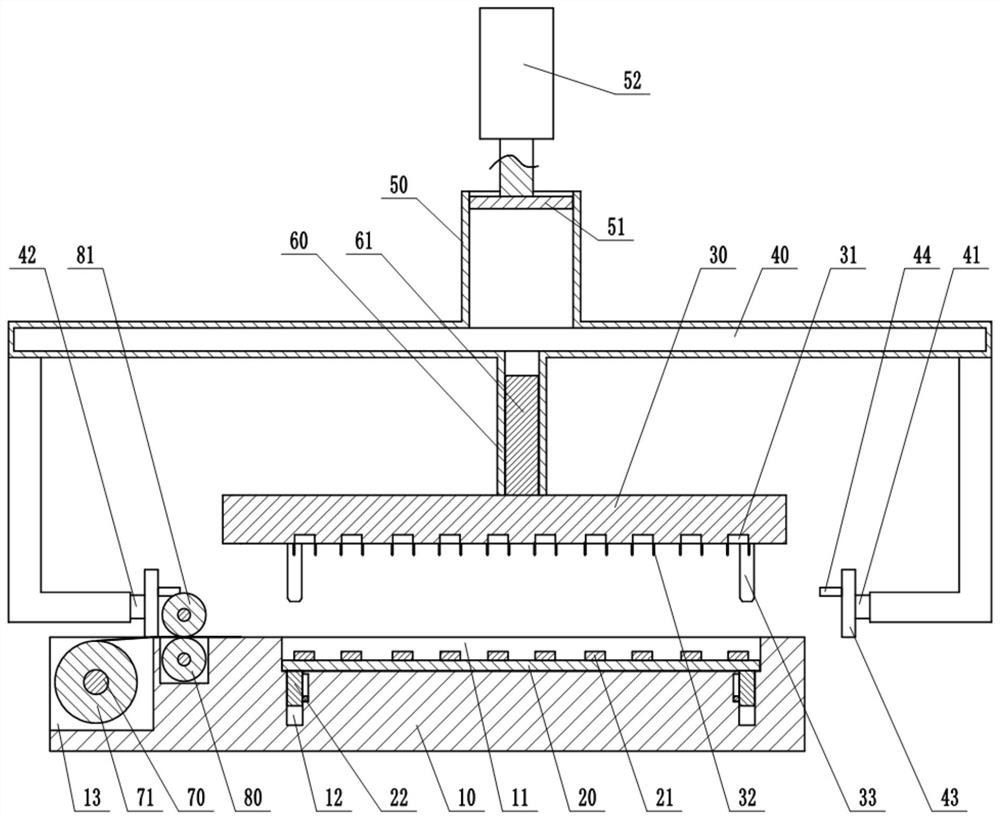

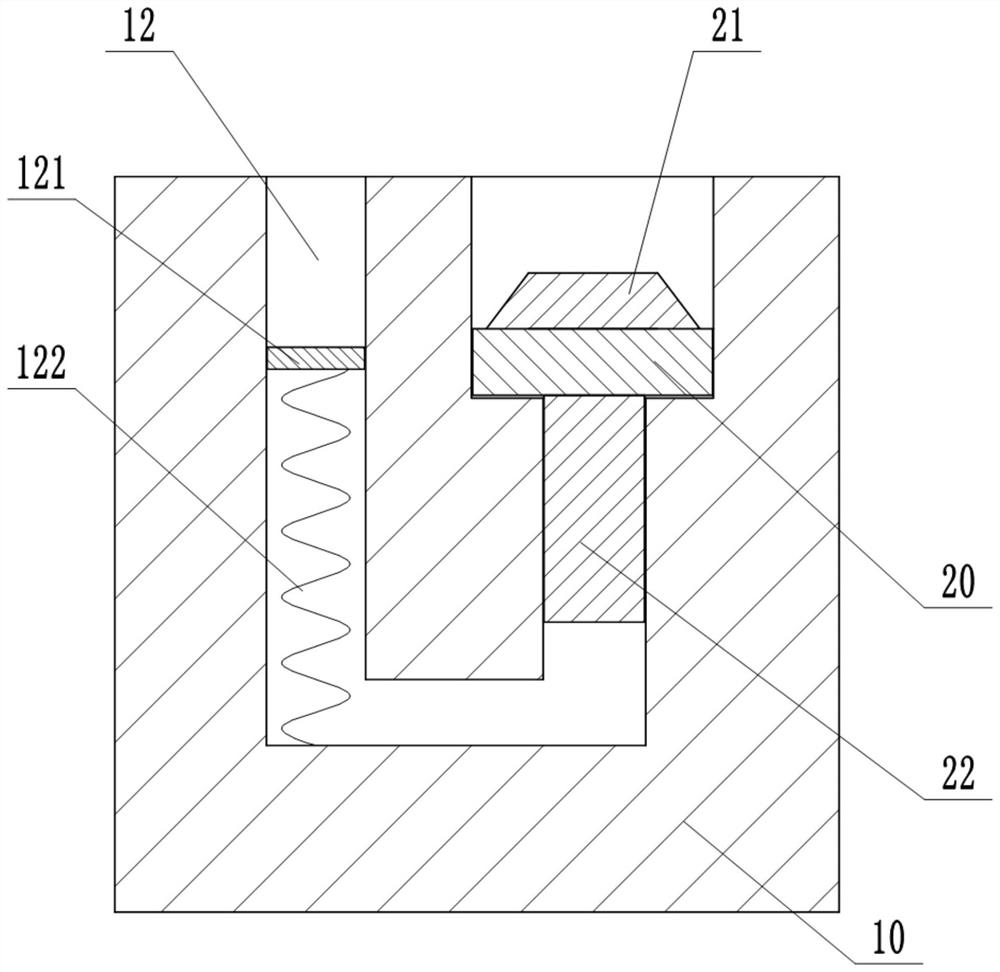

[0023] This embodiment is basically as figure 1 , figure 2 Shown: a suture equipment for silicon steel normalization, including a frame, a power mechanism, a steel belt feeding mechanism, a fixed seat 10, and a movable seat 30 located above the fixed seat 10, and a plurality of straight lines are arranged on the movable seat 30 The groove 31 is welded with punching knives 32 located on opposite sides of the groove 31, and the punching knives 32 are used to punch out openings on the silicon steel sheet. The fixed seat 10 is provided with a concave cavity 11, and a convex template 20 is slidably connected in the concave cavity 11. A plurality of bumps 21 are integrally arranged on the convex template 20, and each bump 21 is matched with a different groove 31. Also have the notch that cooperates with 32 stamping knives on the 20, 32 stamping knives can be inserted in the notch.

[0024]Four jacking mechanisms are arranged on the fixed seat 10 , and the four jacking mechanisms ...

Embodiment 2

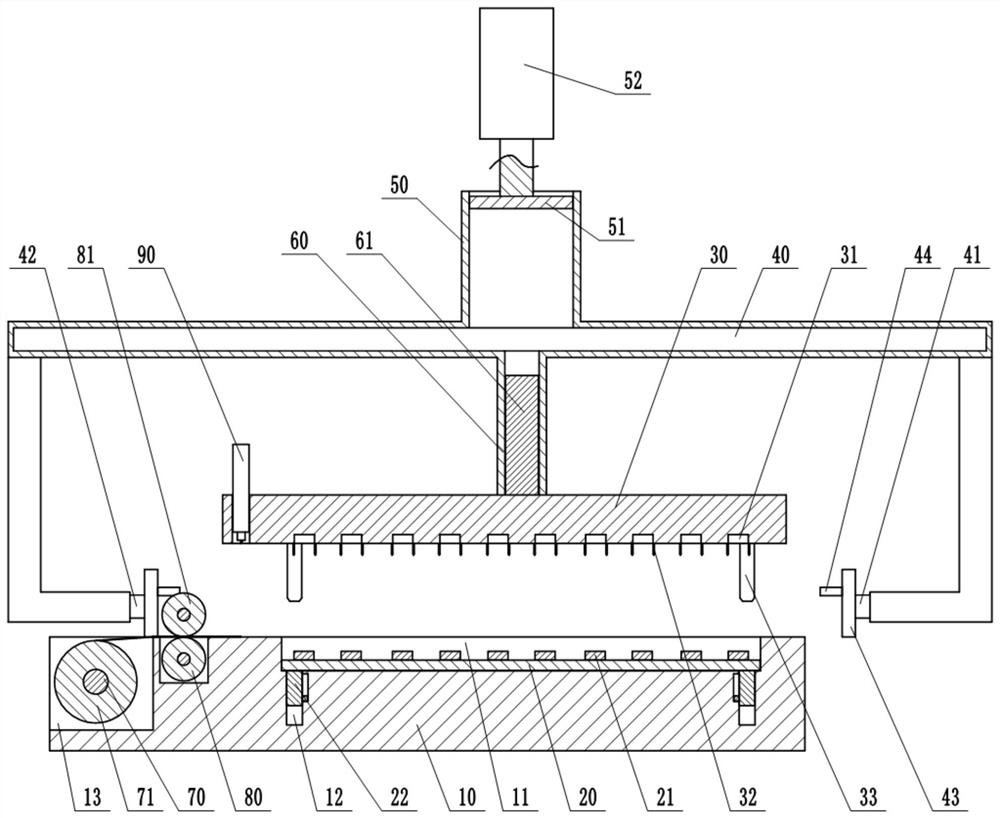

[0031] The difference between this embodiment and Embodiment 1 is that: image 3 As shown, in this embodiment, a kind of sewing equipment for normalizing silicon steel also includes a cutting mechanism for cutting off the steel strip and a rolling mechanism for compacting and sewing the silicon steel. Cylinder 90, the piston rod of cylinder 90 is provided with cutter. After the steel belt feeding mechanism makes the steel belt pass through each opening on the silicon steel sheet successively, the air cylinder 90 is operated to control the movement of the cutting knife, and the steel belt can be cut off by the cutting knife.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com