Air floatation vertical movement device

A technology of vertical motion and air flotation, applied in the direction of tool storage devices, electrical components, electrical components, etc., can solve the problems of complex structure, cumbersome process, huge overall structure, etc., and achieve reduced structure, reduced size, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

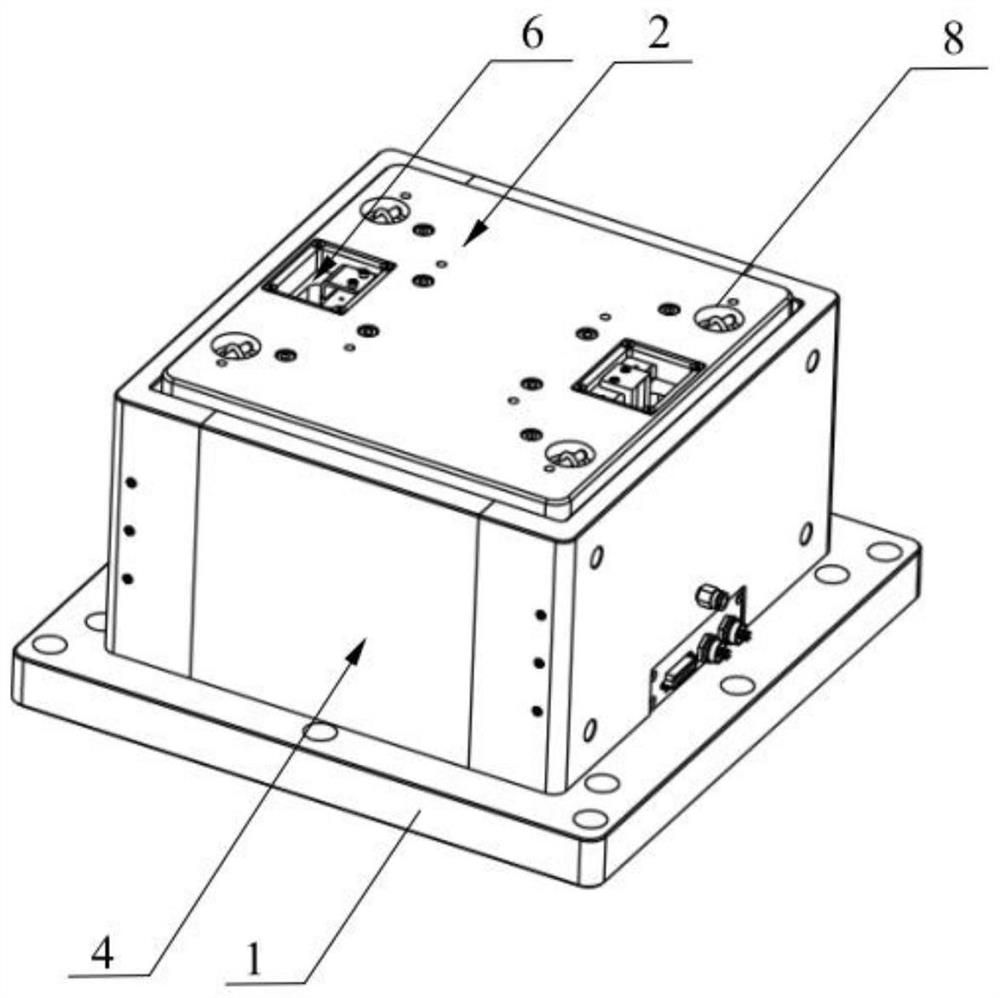

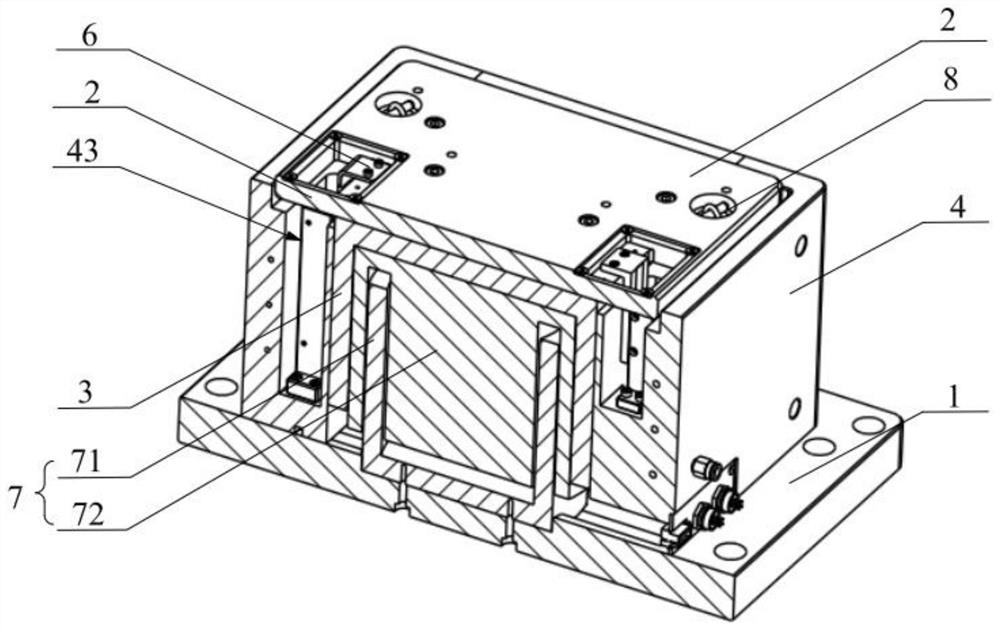

[0038]This embodiment provides a gas floating vertical moving device, which relates to the field of integrated circuitry manufacturing, such asFigure 1 to 4 As shown, the air floating vertical migration device includes a tray 2, a motor 7, a gas floating shaft 3, and a gas floating sleeve 4 in which the air floating shaft 3 is connected, the air floating shaft 3 is connected to the tray 2, the air floex 3 and the air float The sleeve 4 forms an air floating rail, and the motor 7 is provided in the air floating shaft 3, and the output of the motor 7 is connected to the air floating shaft 3, and the motor 7 drives the air floating shaft 3 to move the tray 2 in the axial direction of the gas floating rail.

[0039]The tray 2 of the present embodiment is used to present the processing workpiece, and the air floating shaft 3 is connected to the tray 2, allowing the air floating shaft 3 to move the tray 2 vertically. A stable gas film is formed between the outer wall of the air floating shaf...

Embodiment 2

[0056]In this first embodiment, an air floating traveling device is disclosed. The first example gas floating shaft 3, the motor 7, the tray 2, and the base 1 are identical to the embodiment, and the difference between the embodiments and the embodiment is only in the implementation. The air floating sleeve 4 is integrally formed. Such asFigure 5 As shown, the air floating sleeve 4 is arranged in an integrated structure, and the processing difficulty of the air flub 4 is reduced, and the processing step is reduced. In this embodiment, a pipeline assembly 5, a pipeline assembly 5 communicates with a gas supply assembly is provided in the air floating sleeve 4, and the gas assembly is transported from the air supply assembly to the guide rail space. The pipe assembly 5 can be provided in the outer wall of the air floating 4 or within the air flop 4.

Embodiment 3

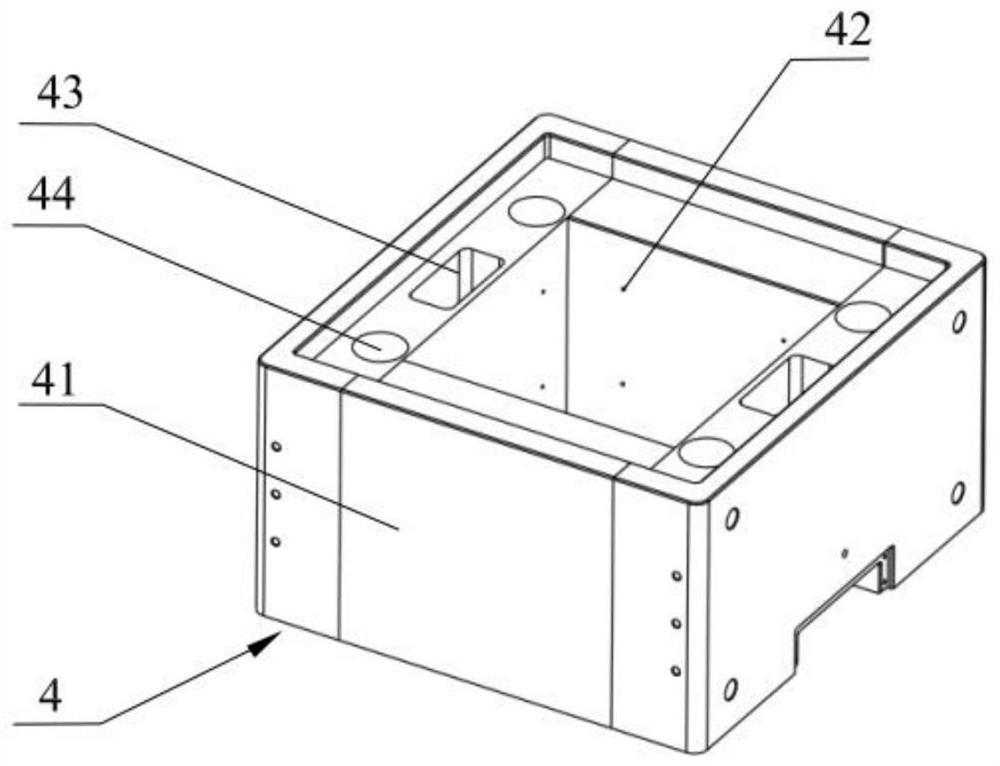

[0058]The third embodiment discloses an air floating vertical moving device, the present embodiment, the tray 2, and the base 1 are the same as the embodiment, and the difference between the present embodiment and the embodiment is only the air flurch of the present embodiment. 4 includes three panels 41, such asFigure 6 As shown, the three panels 41 are connected to each other, and the air floating shaft 3 of the present embodiment is also three prisms. That is, the air floating sleeve 4 includes three inner walls, and the air floating shaft 3 includes three outer walls, and the pipe assembly 5 can be disposed in the outer wall of the air floating sleeve 4, and may be embedded within the air floating sleeve 4, as long as the transport gas function is achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com