Printer structure for preventing printer head wiredrawing

A printer and print head technology, applied in the field of printing, can solve problems such as troubles, influence on the appearance of printed products, and wire drawing, and achieve the effect of quick and convenient use, simple and reasonable structure, and avoid wire drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

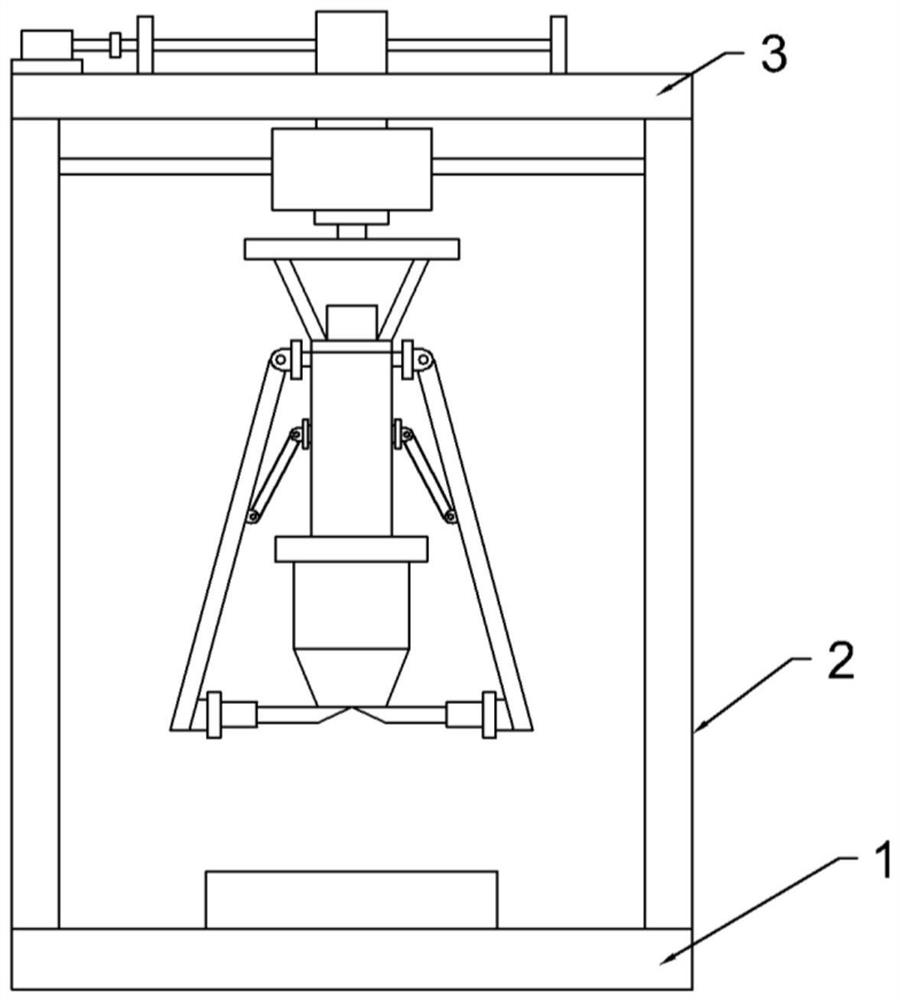

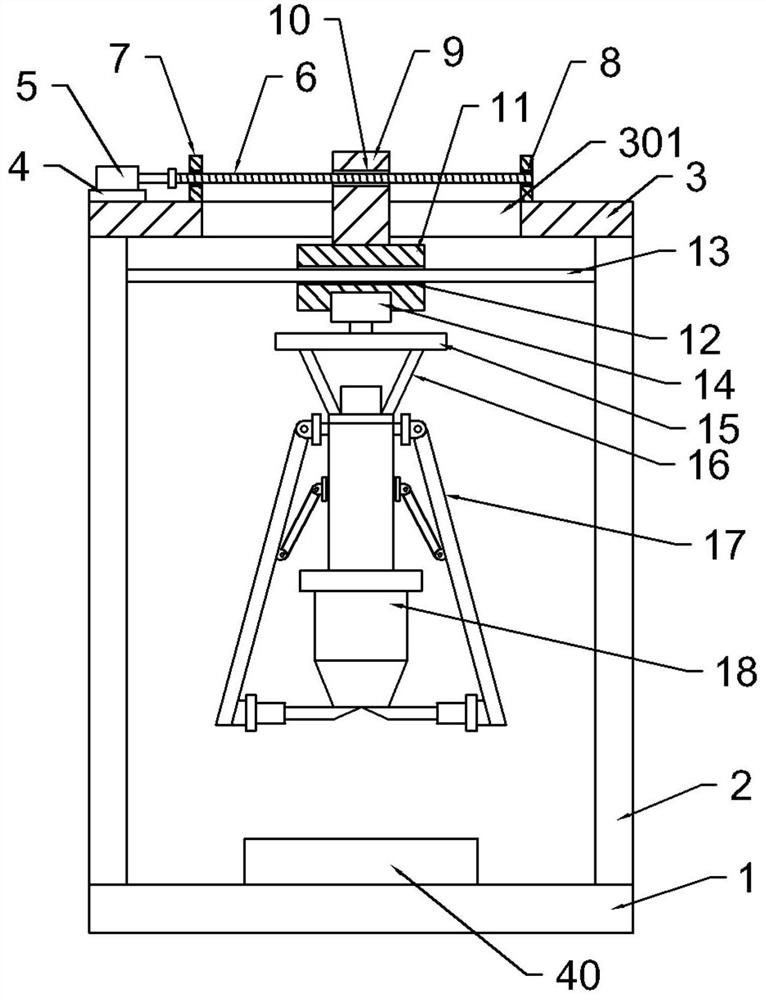

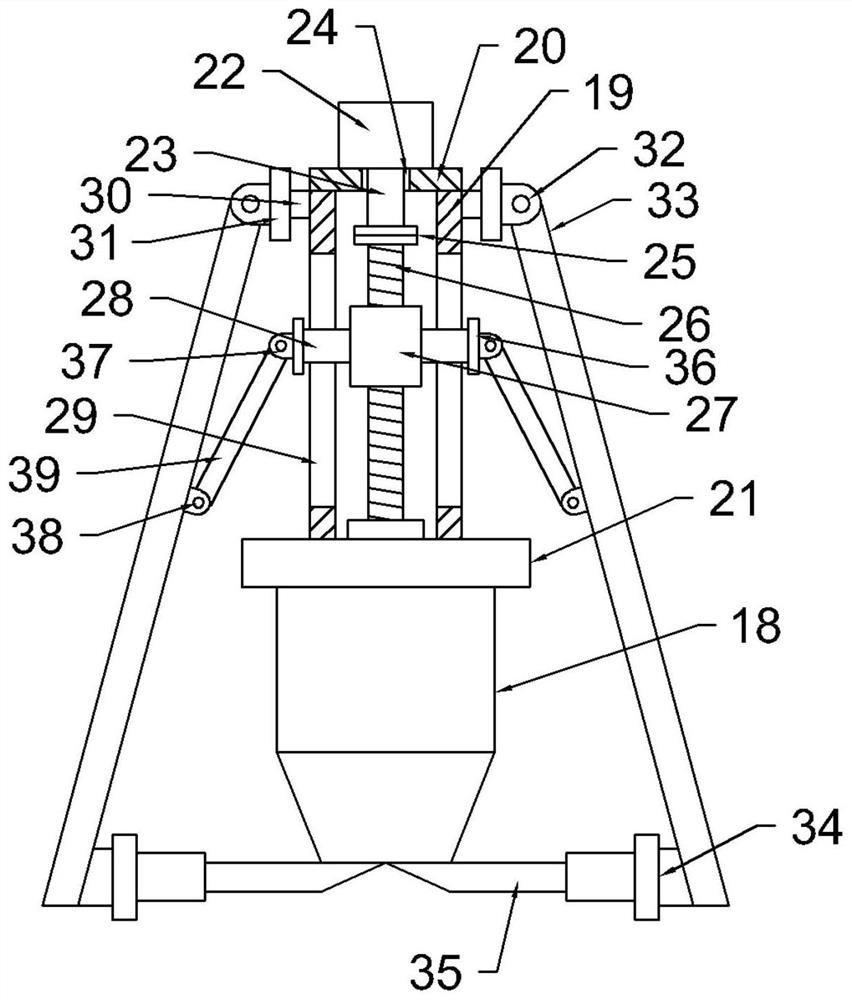

[0022] see Figure 1-4 , according to an embodiment of the present invention, a printer structure for preventing the printer head from being drawn, includes a base 1, a support frame 2 is installed on the top of the base 1, a top plate 3 is fixedly installed on the top end of the support frame 2, and the top plate 3 A motor base 4 is fixedly installed on the top side, and a drive motor 5 is fixedly installed on the motor base 4. The end of the output shaft of the drive motor 5 is connected with a screw rod 6. The screw rod 6 is parallel to the top plate 3, and the screw rod 6 runs along the top plate. 3. Set in the length direction, the top of the top plate 3 is symmetrically installed with the fixed plate 7 along the center, the screw rod 6 is rotationally connected with the fixed plate 7 through the connecting bearing 8, the top center of the top plate 3 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com