PUR and glue point transfer compounding process

A composite process and glue point technology, which is applied in the direction of lamination device, lamination auxiliary operation, lamination, etc., can solve the problems of low efficiency and high labor intensity of textile process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

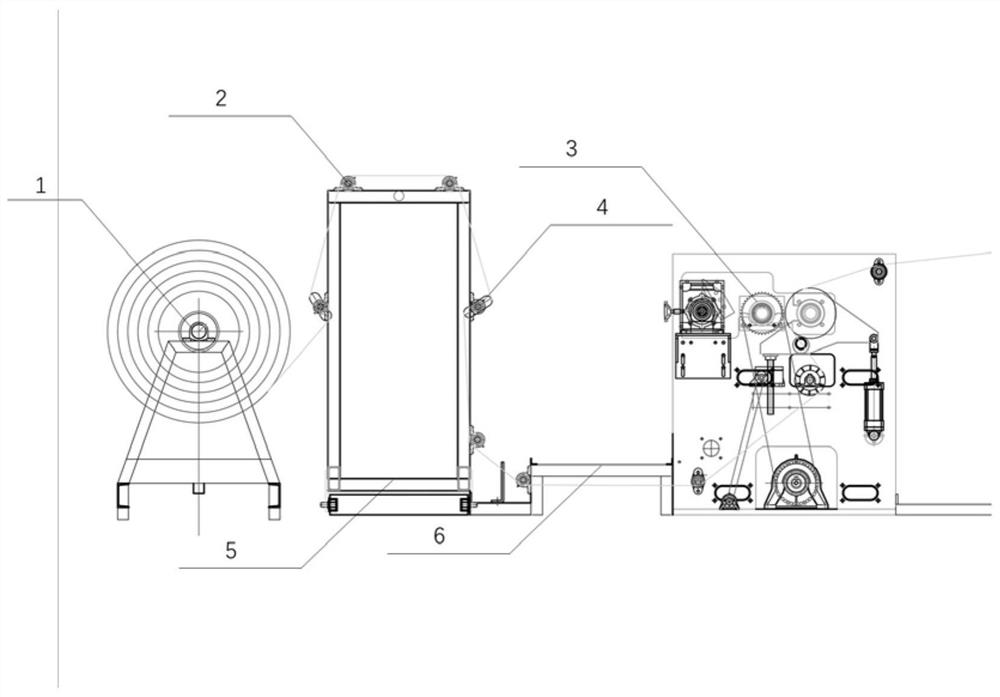

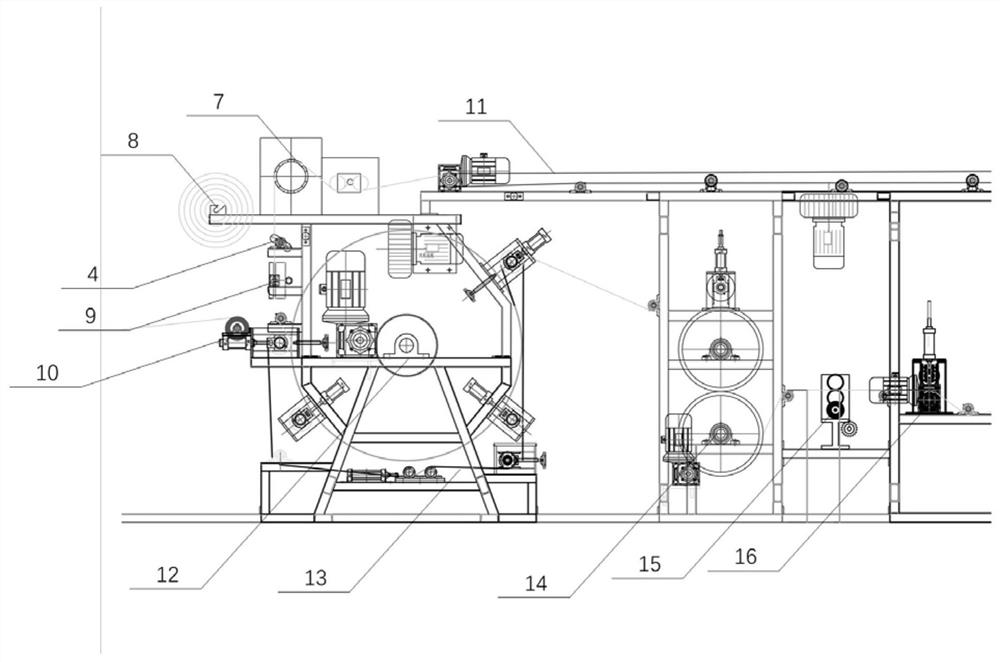

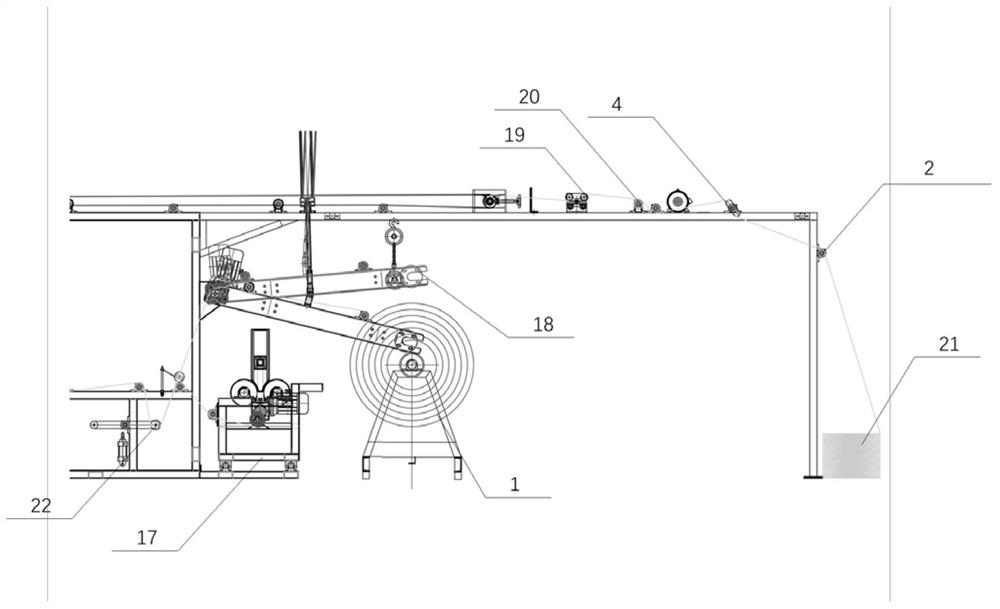

[0025] Example: such as Figure 1-5 As shown, a PUR and glue dot transfer composite process includes the following processes:

[0026] Step 1: The cylindrical front fabric located in the lining unwinding 1 of the bracket A is sent to the fabric expander 4 on the front frame 5 through the fabric guide roller 2 to flatten the cylindrical front fabric;

[0027] Step 2: The flattened front fabric is directionally transferred to the PUR glue dot transfer dual-purpose gluing device 3 under the driving action of the pedal for gluing;

[0028] Step 3: The front fabric that has been glued is transferred to the opening device 10 for opening operation to prevent the fabric from wrinkling and make the fabric reach the required width for production. The unused front fabric will be unwound by the front fabric unwinding device 8 Temporary storage of volumes;

[0029] Step 4: The rear fabric 21 is transported to the fabric expander 4 by the cloth guide roller and then flattened. The flatten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com