Patents

Literature

38results about How to "Save the workshop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing n-phenylglycinonitrile

ActiveCN101514170ARapid responseModerate responseCarboxylic acid nitrile preparationOrganic compound preparationAutomatic controlAcetonitrile

The present invention provides a method for preparing n-phenylglycinonitrile, wherein the method comprises a step of executing condensation reaction for generating n-phenylglycinonitrile when the phenylamine and glycolonitrile are used as raw materials. The invention is characterized in that according to the continuous production method, the raw materials continuously pass through a pipe type preheater, a pipe type mixer, a pipe type reactor and a reaction still for executing condensation reaction for generating the n-phenylglycinonitrile. The method of the invention has the advantages of fewer devices, simple and brief technical route, saved costs of man power, device, raw materials, energy, etc., improved operating environment, extraordinary automatic control realization, excellent guaranteed safety production operability and continuity, equitability and stability of production thereby guaranteeing the stability of product quality, increasing the product purity and yield. The product purity in the invention is above 95.5%, and the product yield is above 99.8%.

Owner:重庆渝化新材料有限责任公司

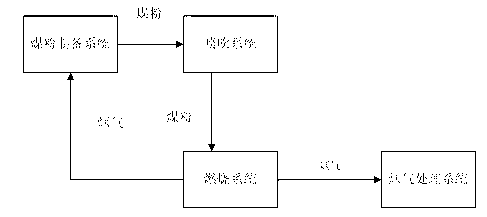

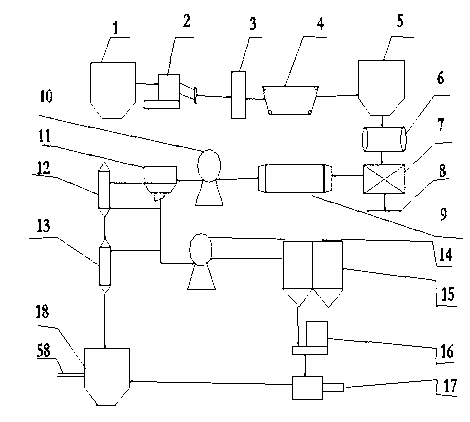

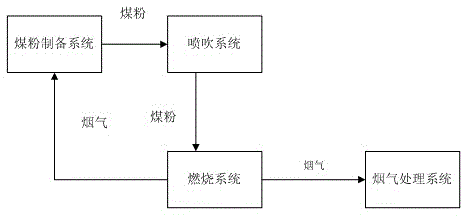

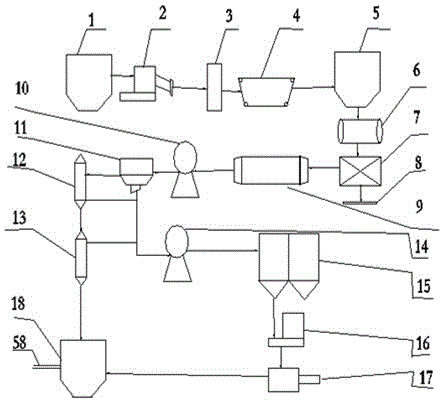

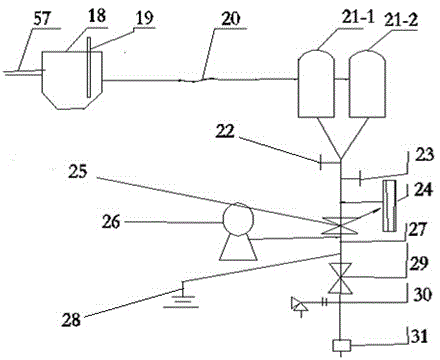

Blended pulverized coal combustion control device and method

InactiveCN103234215ABurn completelyImprove combustion efficiencyCombustion regulationLump/pulverulent fuel feeder/distributionCombustion systemThermodynamics

The invention discloses a blended pulverized coal combustion control device and method. The device organically integrates a pulverized coal preparation system, an injection system, a combustion system and a smoke processing system. A complete set of the device prepares pulverized coal through a ball mill, the injection system adopts a direct parallel-tank injection process, the grain size of the blended pulverized coal entering a combustion furnace is 80-120 mum, and the excess air coefficient is controlled to be 1.05-1.36. The combustion furnace conducts combustion reaction through double hearths, and when combustion reaction is conducted in one hearth, smoke enters another hearth to work in a circulation mode through a pipeline in the furnace. The processing system is arranged for discharged smoke, sulfur obtained by desulfurizing the discharged smoke can be used as a by-product of sulfur ointment to be sold, and secondary pollution is not caused. By means of the device, combustion efficiency of the blended pulverized coal is better than that of other devices and higher than 88%, and the blended pulverized coal combustion control device and method has the advantage of being simple in process, few in devices, less in covered area, short in plants, less in building investment, convenient to measure and the like. The device can also be applied to combustion of other solid fuels.

Owner:KUNMING UNIV OF SCI & TECH

Active peptide fruity beer and its preparing method

InactiveCN1858174ALong soaking timeLow costAlcoholic beverage preparationFood ingredientsFruit juicePhosphoric acid

The present invention relates to beer, and especially active peptide and fruity beer and its preparation process. The active peptide and fruity beer is superior to available peptide beer and fruity beer. The active peptide and fruity beer is prepared with soybean protein peptide powder 0.2-0.5 wt%, sodium carboxymethyl cellulose 0.05-0.15 wt%, fructose syrup 1.5-2.5 wt%, sweetener 0.05-0.15 wt%, citric acid 0.01-0.1 wt%, phosphoric acid 0.005-0.025 wt%, sodium citrate 0.001-0.02 wt%, CO2 0.4-0.65 wt% and water for the rest. The mixed mash is pumped into the CO2 mixing tank while maintaining tank pressure in 0.15-0.6 Mpa. The active peptide and fruity beer is cool, tasty and refreshing, and good for health, and the preparation process is simple and low in resource consumption.

Owner:哈尔滨三乐生物工程有限公司

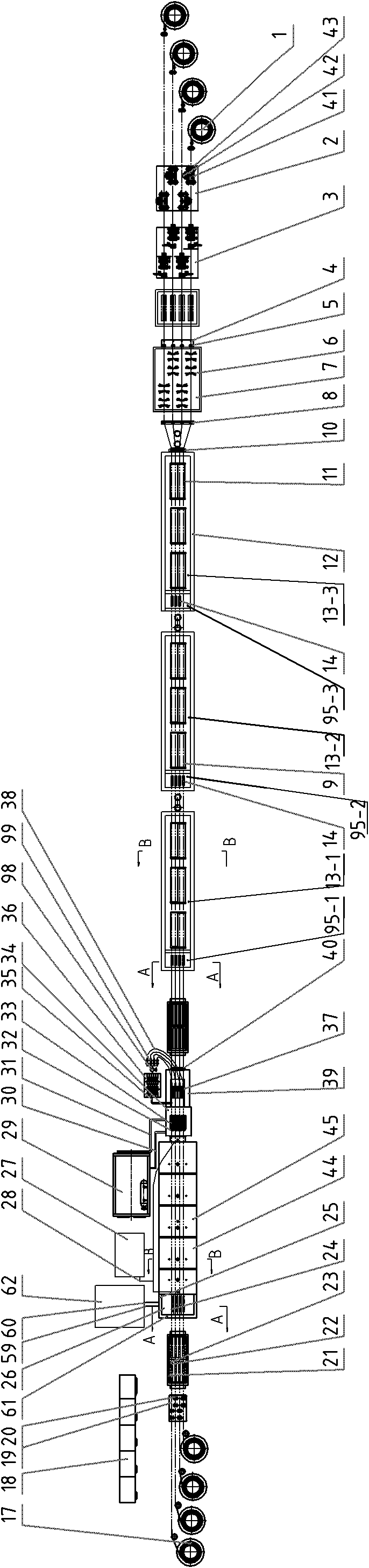

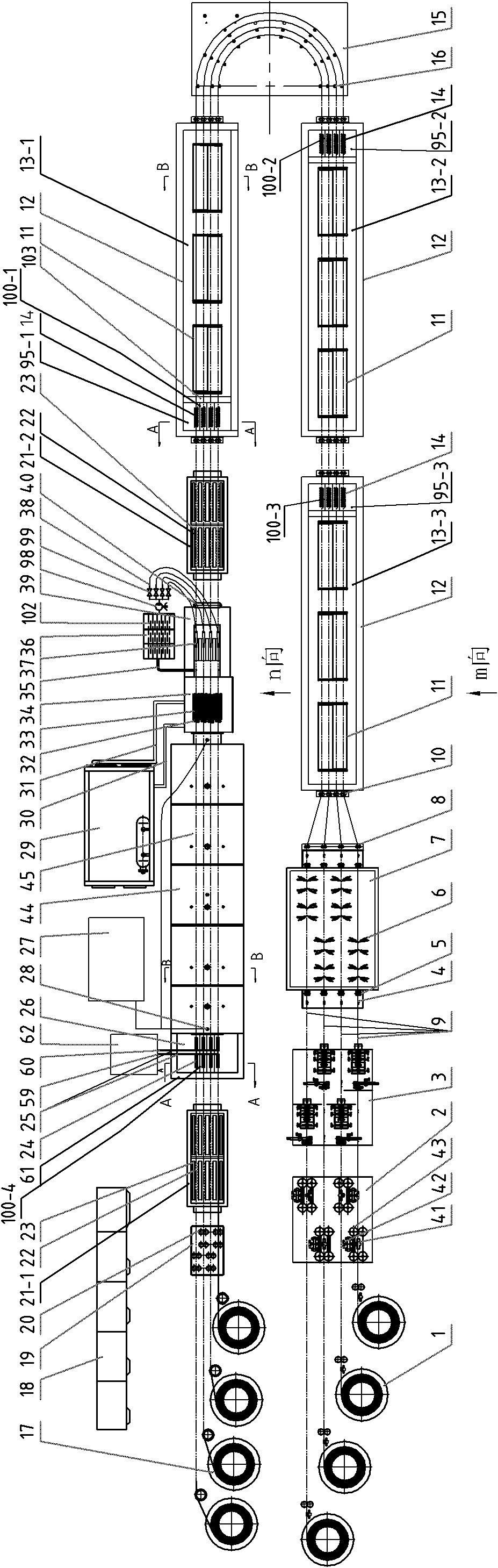

Multifunctional one-furnace multi-strip quick high-efficiency heat treatment production line and process for bimetal strip saw blades

InactiveCN102534169AImprove efficiencyIncrease production capacityFurnace typesHeat treatment furnacesMultiple functionLarge capacity

The invention discloses a multifunctional one-furnace multi-strip quick high-efficiency heat treatment production line and a process for bimetal strip saw blades, and relates to a heat treatment production line and a quenching process for bimetal strip saw blades. By the production line and the process, a technology for heating and cooling the saw blades quickly is implemented, the saw blades have high quality, and high efficiency, high capacity, low input, low cost and low energy consumption are achieved. Quick step quenching is performed by a deep cooling, water cooling, air cooling and nitrogen composite cooling process, so that the high efficiency and high capacity of production and the high quality of the saw blades can be ensured; and all process equipment is integrated into one production line, all processes such as quenching, tempering, sand blasting, cleaning, drying, marking, oiling, straightening and the like are finished on one production line, and a plurality of band saw blades of various specifications can be produced on one production line simultaneously. After the production line is implemented, the capacity of the saw blades is improved by about 3 times, the quality of products is improved by about 30 percent, energy such as electricity, water, oil, gas and the like is saved by over 200 percent, project investment is saved by over 200 percent, plant and land are saved by over 150 percent, production cost is reduced by over 50 percent, and the contradiction and technical bottleneck problem of conventionally exchanging quality for yield and exchanging high input for high capacity for years are radically solved.

Owner:曹玉贵

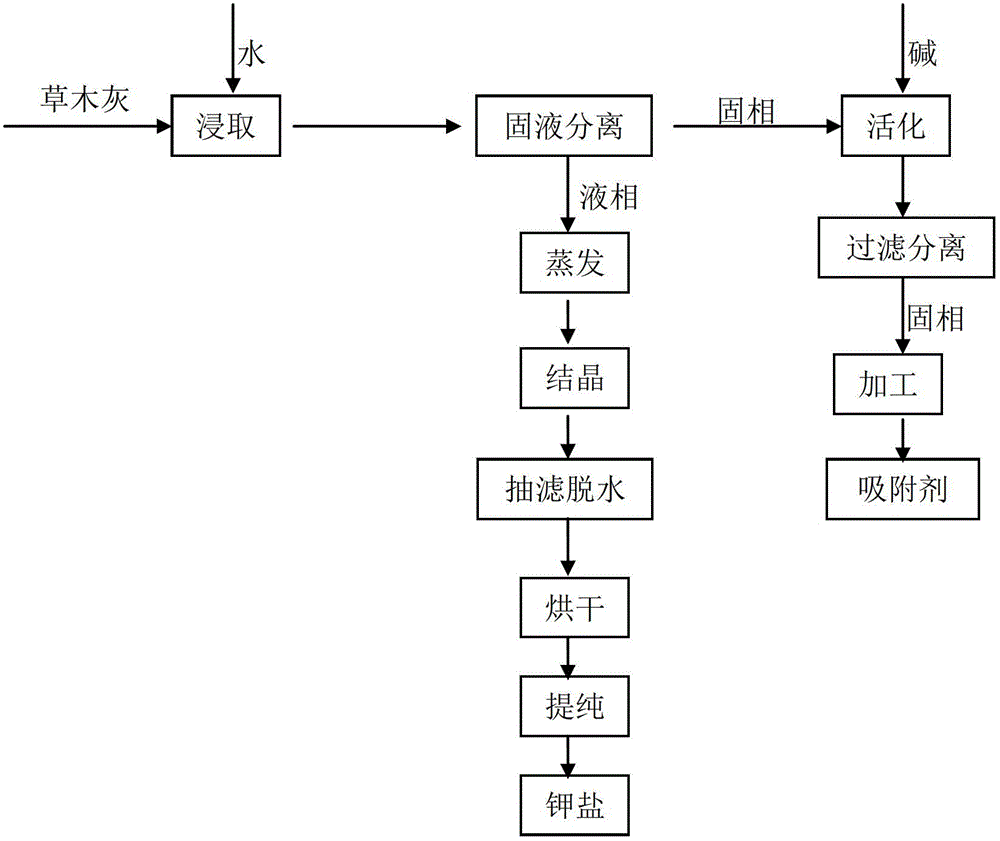

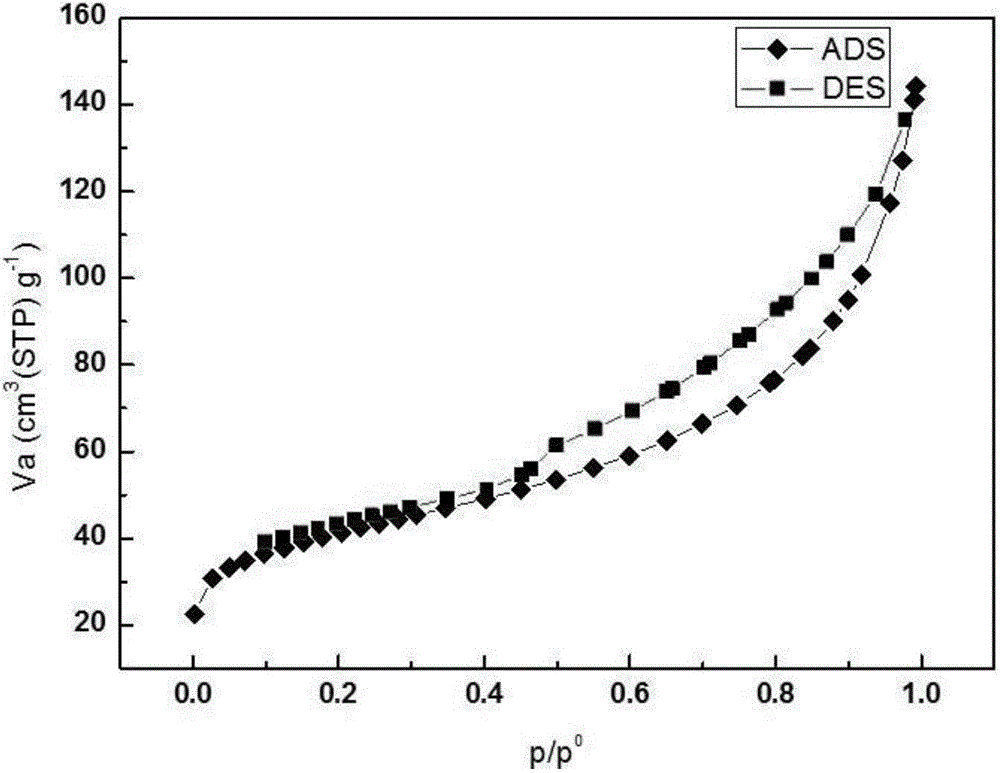

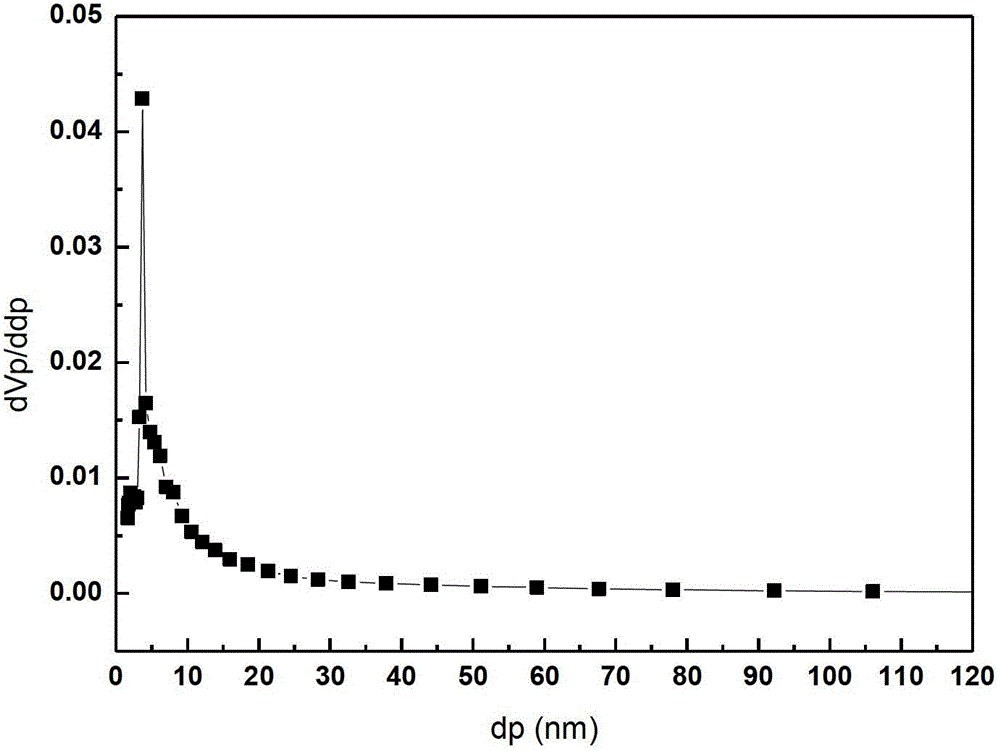

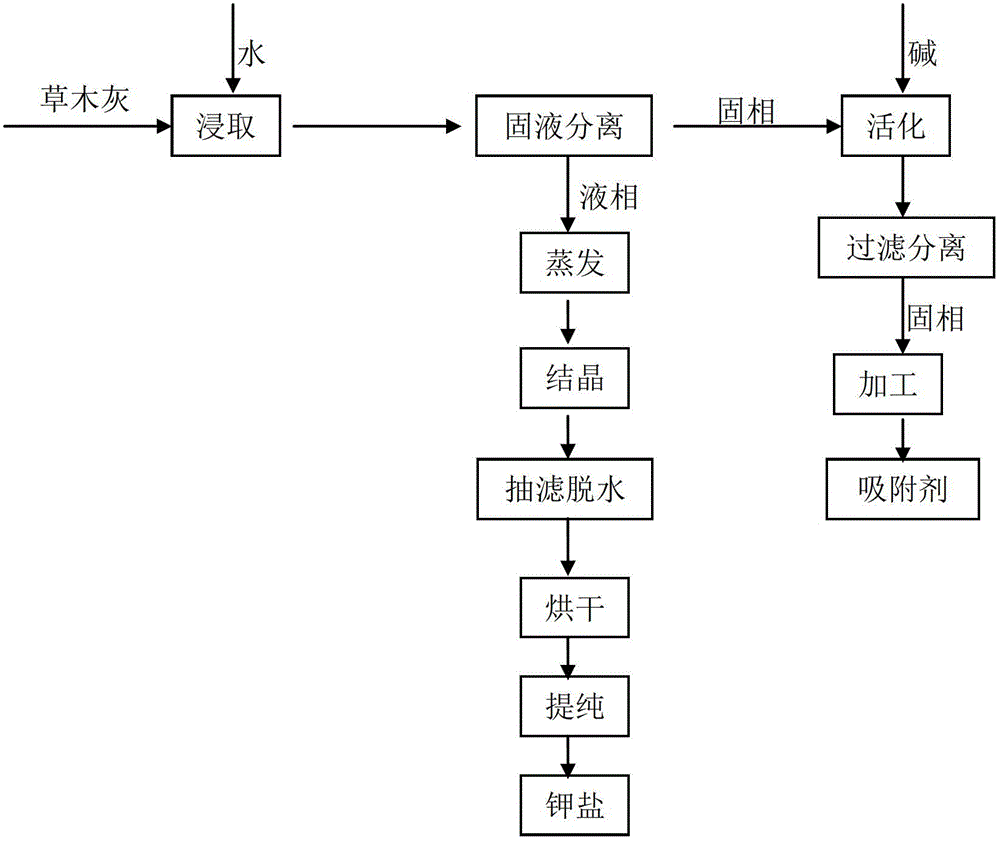

Comprehensive utilization method of plant ash for biomass power plant

ActiveCN102744238AReduce manufacturing costIncrease profitSolid waste disposalAlkali metal sulfite/sulfate purificationSocial benefitsCombustion

The invention provides a comprehensive utilization method of plant ash for a biomass power plant. The method comprises the following steps: extracting sylvite and preparing an adsorbent, wherein plant ash generated by combustion in a power plant is extracted with deionized water, and soluble sylvite in the plant ash is dissolved, and the sylvite is obtained by distilling and crystallizing the sylvite solution after solid and liquid are separated; activating the plant ash slag which is subjected to sylvite extraction with alkaline, is washed with acid or deionized water until the mixture is neutral, and is baked, grinded, screened and granulated to obtain the adsorbent. According to the method, the plant ash generated in combustion in the biomass power plant can be sufficiently utilized, waste is changed to be profitable, the problem of solid waste generated in the biomass power plant can be effectively solved, environmentally-friendly and economical popularization and operation of the biomass power plant can be facilitated. The method has the advantages of excellent economical, environmental and social benefits, simple process, low cost, and convenience for scale production.

Owner:NANJING UNIV OF TECH

High-strength environmentally-friendly rubber powder rubber plate and preparation method thereof

InactiveCN101665599AImprove mechanical propertiesHigh mechanical strengthFlat articlesPolymer scienceWastewater

The invention provides a high-strength environmentally-friendly rubber plate prepared by directly utilizing waste rubber powder and a method for preparing the rubber plate. Components selected by theinvention and the proportion of the components ensure that the rubber plate has good mechanical properties. The tensile strength of the rubber plate is between 3.49 and 5.3, the elongation at break isbetween 94 and 150 percent, and the strength is 66 DEG. The method has the mainly characteristics of using the waste rubber powder to directly produce the rubber plate, and saving working proceduressuch as desulfurization and refining during the production of regenerated rubber. The method saves a large amount of special equipment, factory buildings, power and manpower, and can also save chemical raw materials such as a softening agent, a tackifier and the like; and in addition, no pollution of waste water, waste gas and flying dust generates in the technological process.

Owner:丹军旗

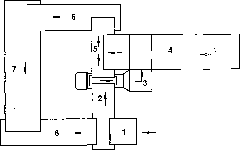

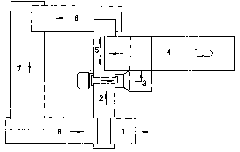

Fresh tea leaf quality automatic control machine set

ActiveCN102187915ASolve the technical problems of quality controlImprove product qualityPre-extraction tea treatmentAutomatic controlEconomic benefits

The invention discloses a fresh tea leaf quality automatic control machine set. A charging hopper is matched and connected with the input end of a charging conveyor belt, the output end of the charging conveyor belt is matched and connected with a charging hopper of a silage machine by a vertical lifter, and a connecting hopper of the silage machine is matched and connected with the input end of a discharging conveyor belt; and one channel of the output end of the discharging conveyor belt is matched and connected with the charging hopper of the silage machine by the vertical lifter, and the other channel of the output end of the discharging conveyor belt is matched and connected with the input end of the charging conveyor belt by an oblique conveyor belt, a quality control machine and a middle conveyor belt. The automatic quality control machine set has the advantages of: 1, solving the technical problem of controlling the quality of fresh tea leaves, and greatly improving the quality of tea products; 2, fulfilling the aim of continuous and automatic production of Wulong tea and red tea for the first time in several hundred years; 3, greatly improving efficiency of labor and reducing labor intensity; and 4, improving economic benefits and international competitive power of tea companies.

Owner:中华全国供销合作总社杭州茶叶研究院

Semi-artificial cultivation method for amanita parvipantherina

InactiveCN103004456AArtificial culture possibleEasy to operateHorticultureBiotechnologyChemical synthesis

The invention relates to a semi-artificial cultivation method for amanita parvipantherina, belonging to the technical field of large fungus culture. The semi-artificial cultivation method is characterized in that a large number of hyphae which are obtained in a laboratory through solid culture are directly inoculated into an outdoor natural habitat; and the hyphae are grown and developed by adding a growth promotion substance to finally grow fruiting bodies. Mycelia are directly induced to fruit by using natural growth conditions; and the method has the advantages of easiness in operation, original ecology, no pollution, energy saving, capability of saving a factory building and the like, and is a more ideal culture mode at present. The amanita is a special and precious large economic fungus, has high value and a wide application range, has potential application prospect in the fields of developing new specific medicines such as anti-tumor medicines, anti-bacterial and anti-viral medicines, sedatives or narcotic and the like, is difficult to develop and apply due to the problems such as valuable and rare resource, difficulty in artificial domestication and inactivity of chemical synthetic products of toxin up to now, is used as a peptide toxin of a biochemical reagent and is worth over one hundred thousand dollars every gram. The fact that the hyphae are difficultly developed into the fruiting bodies under the culture conditions is a key factor for restricting the artificial culture; and taking the amanita parvipantherina for instance, certain breakthrough is realized aiming at the problem, so that the artificial culture of the parvipantherina becomes possible, and conditions are created for sustainable development and utilization of the resource.

Owner:YUNNAN UNIV

High strength environmental protection type glue powder rubbor plate and its preparation method

InactiveCN1911992AHigh mechanical strengthIncrease water permeability and breathabilityVulcanizationActive agent

The present invention discloses high strength environment friendly rubber plate and its making process. The material for the rubber plate includes waste rubber powder 80-120 weight portions, vulcanizing accelerator 0.5-0.8 weight portion, vulcanizing activator 0.5-0.8 weight portion, and sulfur 1.5-1.7 weight portions. The making process of the rubber plate includes the following steps: weighing the material components; drying the waste rubber powder; mixing all the material and molding; and vulcanizing at temperature of 120 -160 deg.c and pressure of 3.4-4.5 kgf / sq cm for 10-20 min. The rubber plate has excellent mechanical performance and may be used in making different rubber products. The present invention has the advantages of simple making process, saving in chemical material and no environmental pollution.

Owner:JINGDONG RUBBER

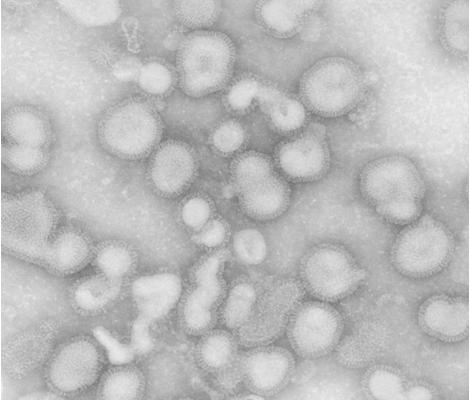

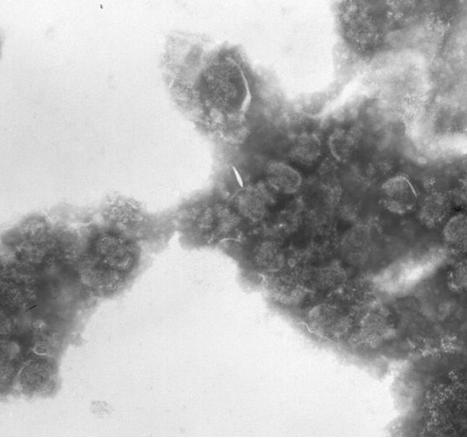

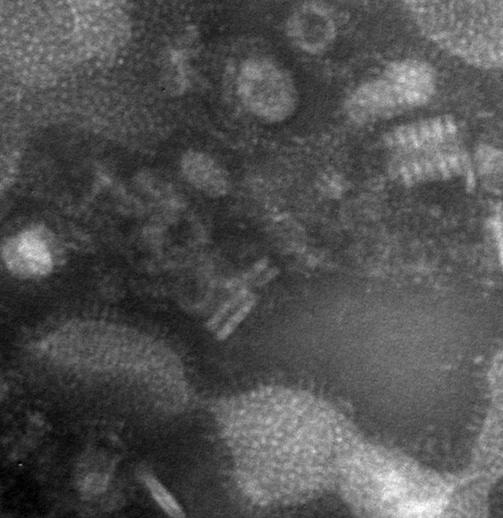

Virus split deactivation method for human influenza virus split vaccine

ActiveCN102614508ASolve the aggregation problemImprove uniformityInactivation/attenuationAntiviralsHuman influenzaVirus

The invention relates to a virus split deactivation method for a human influenza virus split vaccine, and belongs to the field of biological pharmacy. A method of firstly purifying and cracking H1N1 type, H3N2 type or B type monovalent influenza totivirus after gradient density centrifugal purification and then deactivating is adopted, so that the virus cracking effect can be improved, the deactivation time can be shortened, the deactivation efficiency can be increased, the using amount of a deactivator can be obviously reduced, deactivation operation steps can be simplified, the contamination risk can be reduced, factory buildings, facilities and energy consumption required for deactivation can be reduced, and the uniformity and the stability of deactivation can be increased.

Owner:长春生物制品研究所有限责任公司

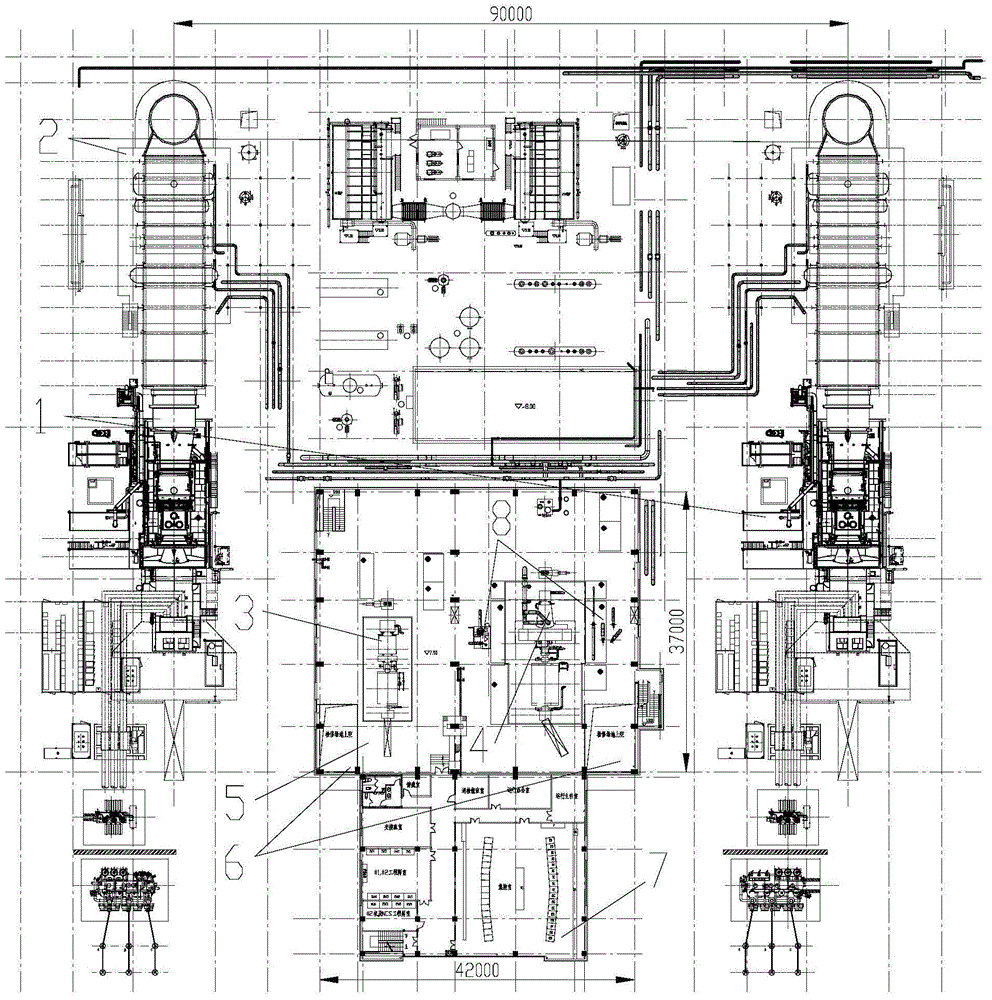

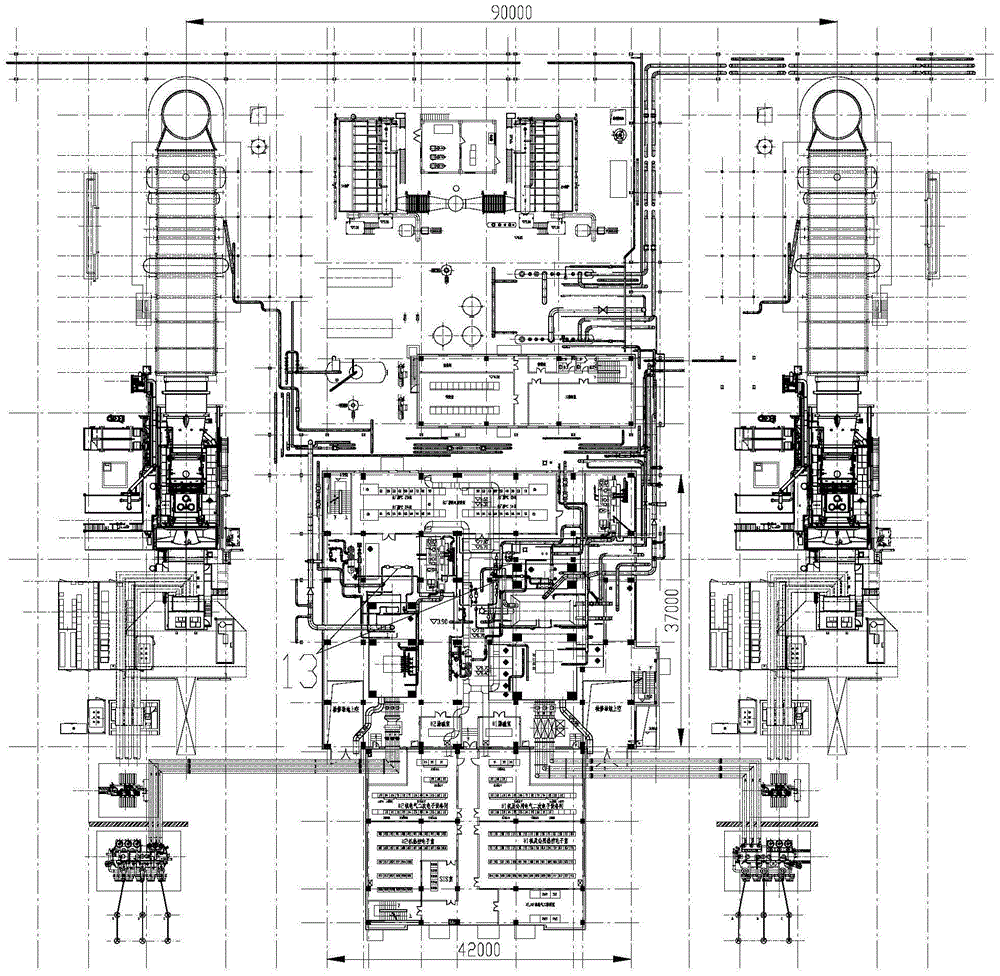

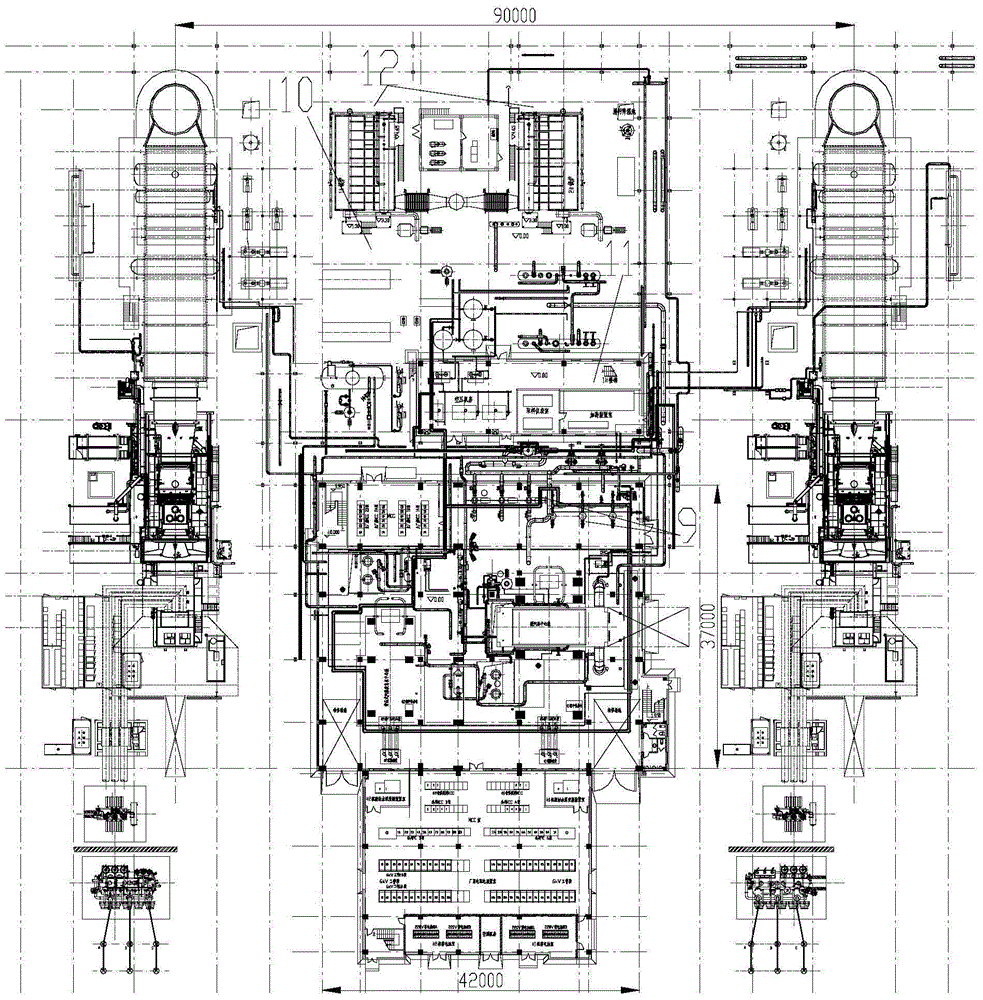

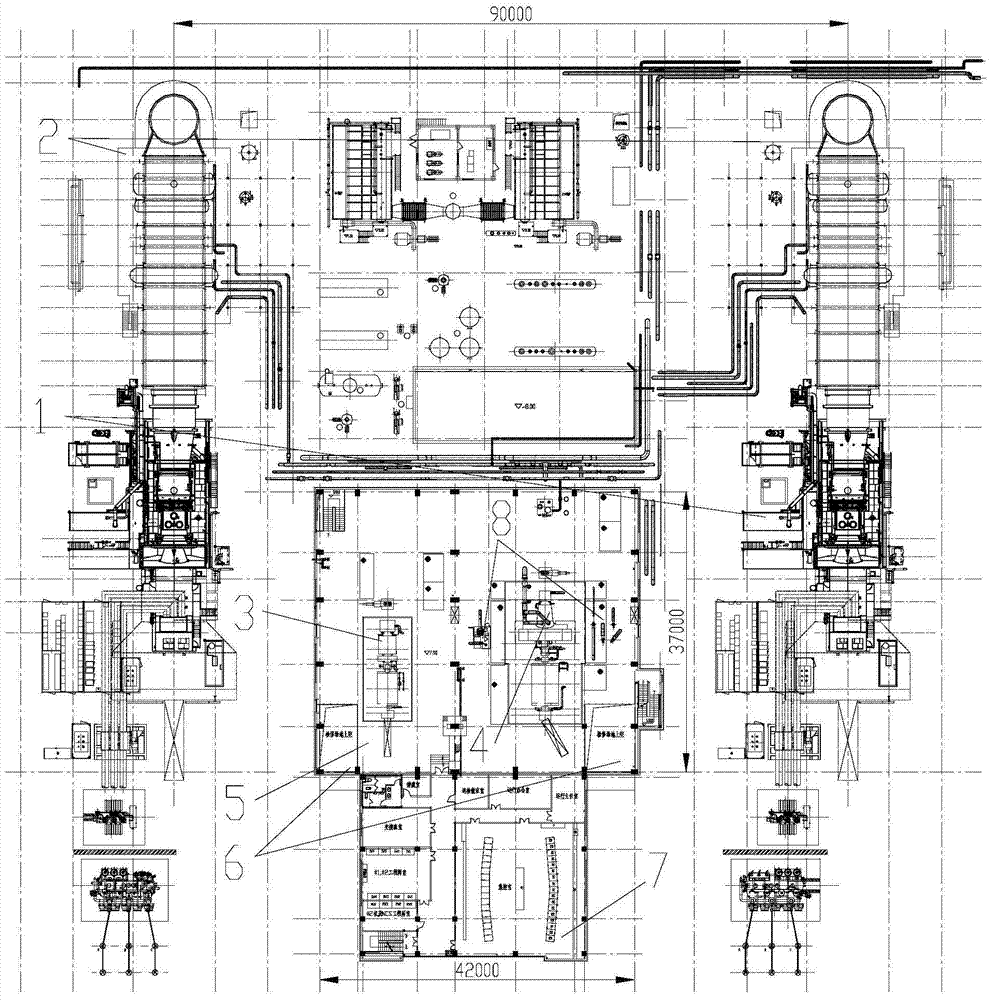

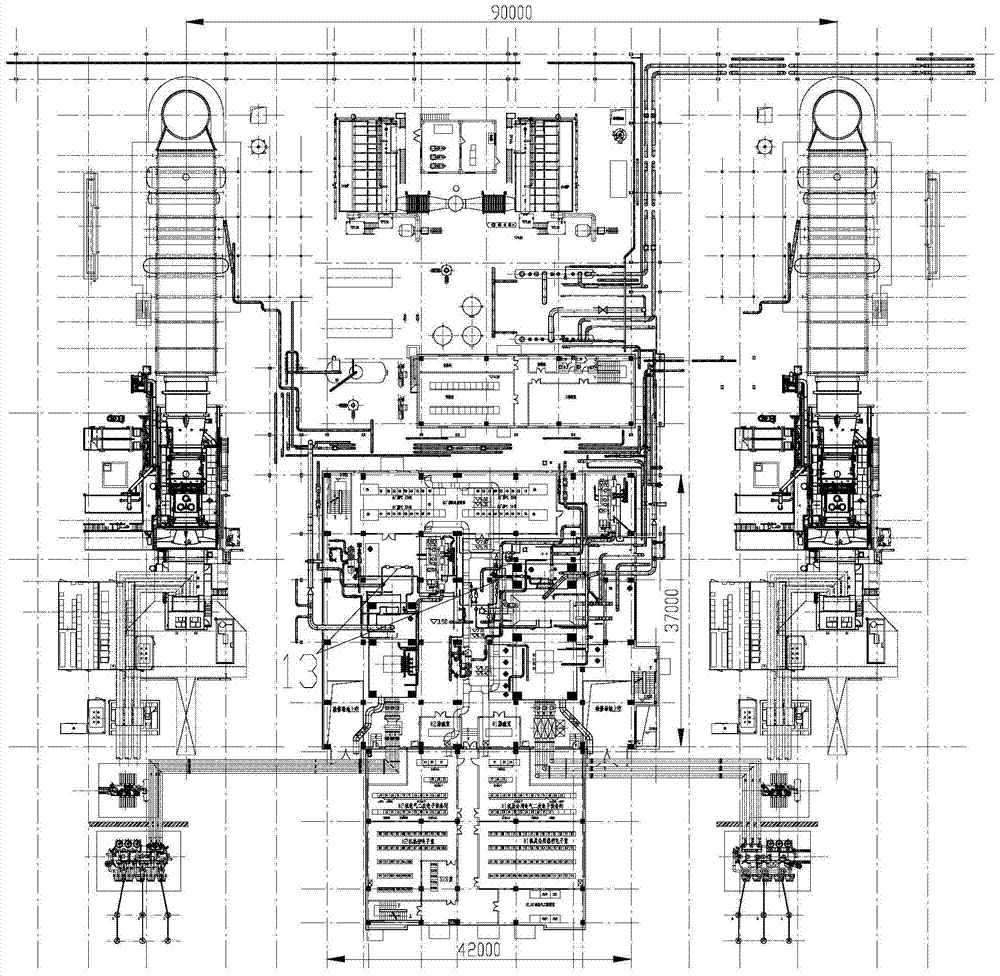

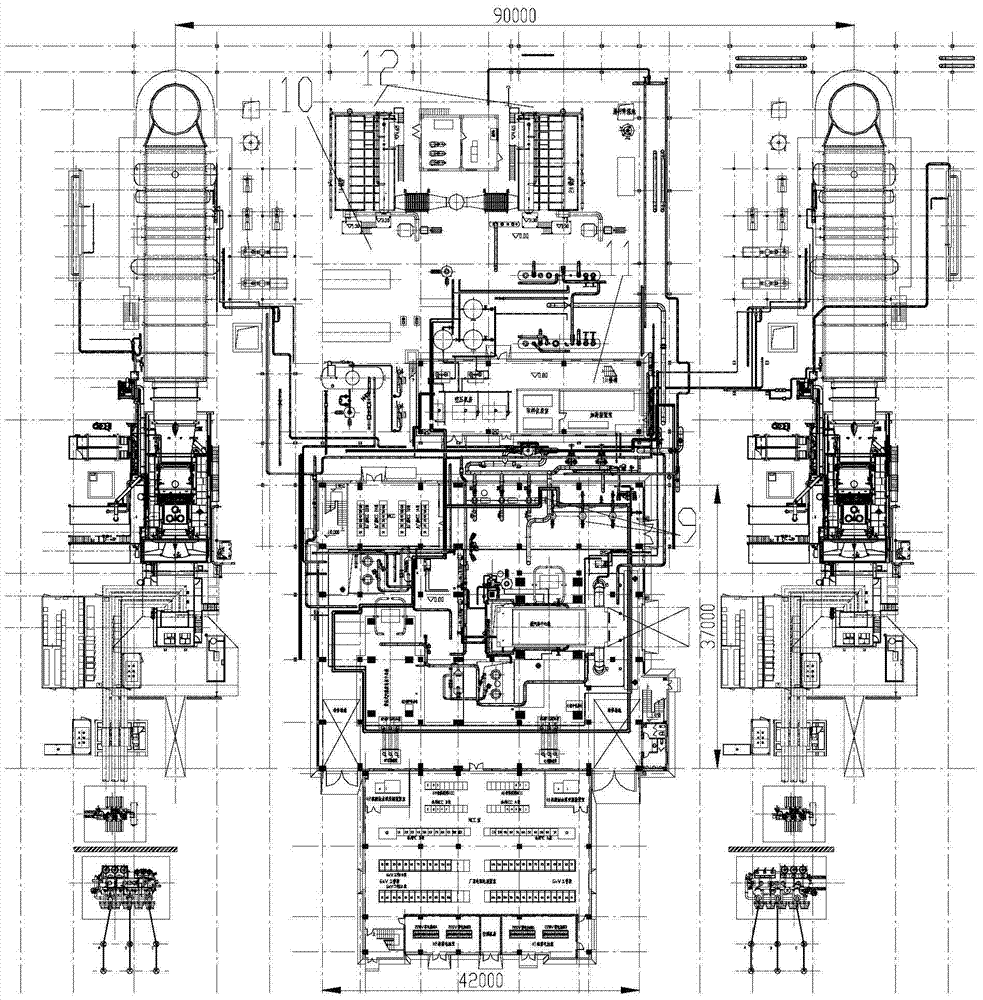

Power island arrangement structure of one-on-one multi-shaft gas turbine extraction condensing back-pressure turbine combined cycle power plant

ActiveCN105822098ASave space in the turbine roomConvenient for compact arrangementCombined combustion mitigationIndustrial buildingsAutomotive engineeringSteam engine

The invention discloses a power island arrangement structure of a one-on-one multi-shaft gas turbine extraction condensing back-pressure turbine combined cycle power plant. The power island arrangement structure comprises two gas turbines which are linearly arranged outdoors in the open air, wherein two waste heat boilers are arranged in a mirror symmetry manner; a steam turbine is arranged in a steam engine room, and the center line of the steam turbine is parallel to the center line of the gas turbines; the steam engine room is an unequal column space combined factory building; a back-pressure turbine side plant has the column space of 5m, 8m and 5m; a plant intermediate layer and an operating floor have the elevation of 3.9m and 7.9m respectively; an overhauling span is not needed, the back-pressure turbine and extraction condensing turbine are respectively and independently provided with independent access holes of 4.91m*9m and 6.15*9m; two travelling cranes of 32t / 5t and 75t / 20t are correspondingly configured; lower chord elevation of the plant is 22.73m; a main plant PC and MCC are respectively arranged on a condenser floor and an intermediate layer; a generator outgoing line is arranged on a 3.9m layer; the installation of a main transformer and a standby transformer of a steam turbine set arranged outside the column A can be canceled, and a centralized control building and an electric room are arranged.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

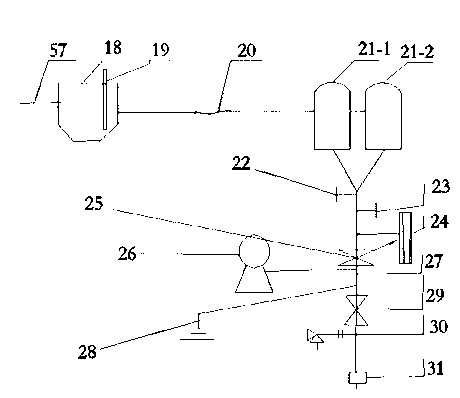

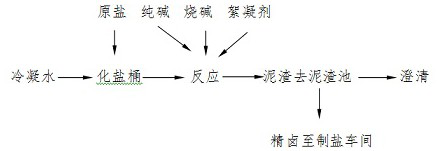

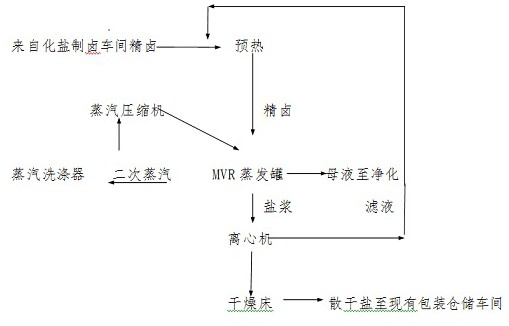

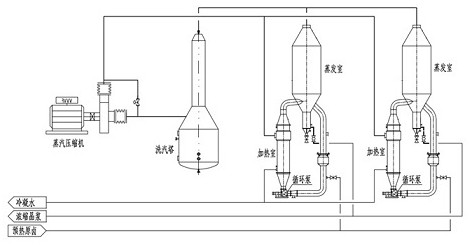

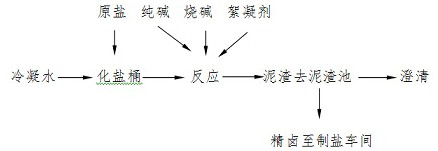

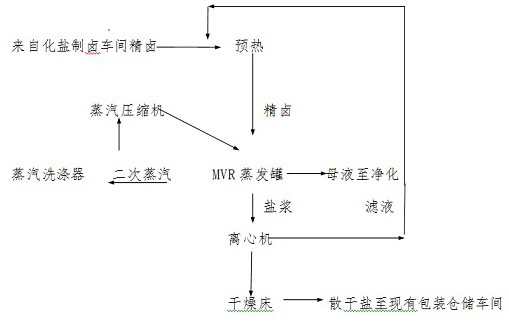

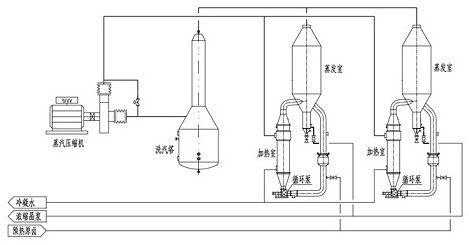

Application method of MVR heat pump evaporation salt production in multi-effect vacuum salt production technology

ActiveCN113577799AAdvanced technologySimple structureHeat pumpsEvaporator accessoriesAir preheaterProcess engineering

The invention relates to an application method of MVR (mechanical vapor recompression) heat pump evaporation salt production in a multi-effect vacuum salt production process technology. The application method comprises an evaporation crystallization process, a brine treatment process, a steam treatment process, a condensate water treatment process and a non-condensable gas treatment process. In the steam treatment process, live steam is introduced into an MVR evaporation device and an air preheater; after entrainment carried by secondary steam evaporated by each effect is removed through a demister, the secondary steam is gathered to enter a scrubber tower, is washed by circulating condensate water in the scrubber tower and then enters a steam compressor to be compressed; and secondary steam is compressed in the compressor and then enters each effect heating chamber to serve as a heat source. According to the application method disclosed by the invention, 40.5% of energy consumption can be reduced; the project construction period is only eight months; few plants, small occupied area and low equipment and facility investment are provided; and the payback period is only 3.34 years.

Owner:SHANDONG CAIYANGZI SALTWORKS

Method for preparing n-phenylglycinonitrile

ActiveCN101514170BRapid responseModerate responseCarboxylic acid nitrile preparationOrganic compound preparationAutomatic controlAcetonitrile

The present invention provides a method for preparing n-phenylglycinonitrile, wherein the method comprises a step of executing condensation reaction for generating n-phenylglycinonitrile when the phenylamine and glycolonitrile are used as raw materials. The invention is characterized in that according to the continuous production method, the raw materials continuously pass through a pipe type preheater, a pipe type mixer, a pipe type reactor and a reaction still for executing condensation reaction for generating the n-phenylglycinonitrile. The method of the invention has the advantages of fewer devices, simple and brief technical route, saved costs of man power, device, raw materials, energy, etc., improved operating environment, extraordinary automatic control realization, excellent guaranteed safety production operability and continuity, equitability and stability of production thereby guaranteeing the stability of product quality, increasing the product purity and yield. The product purity in the invention is above 95.5%, and the product yield is above 99.8%.

Owner:重庆渝化新材料有限责任公司

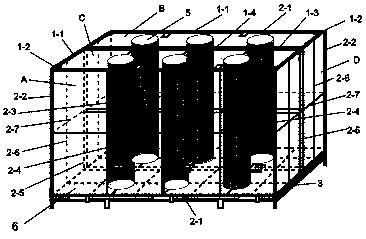

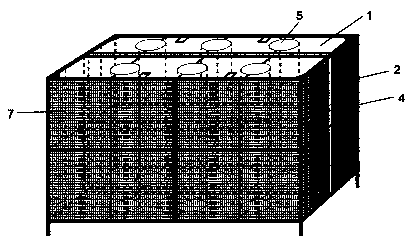

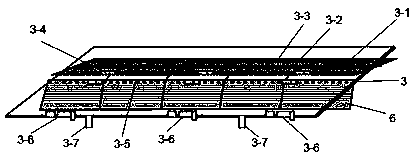

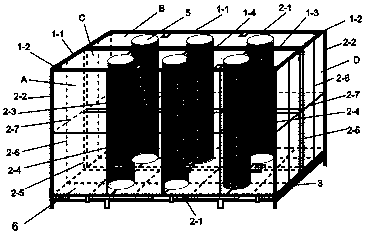

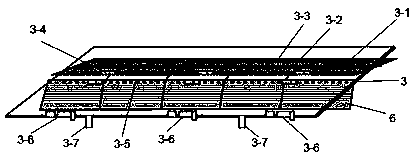

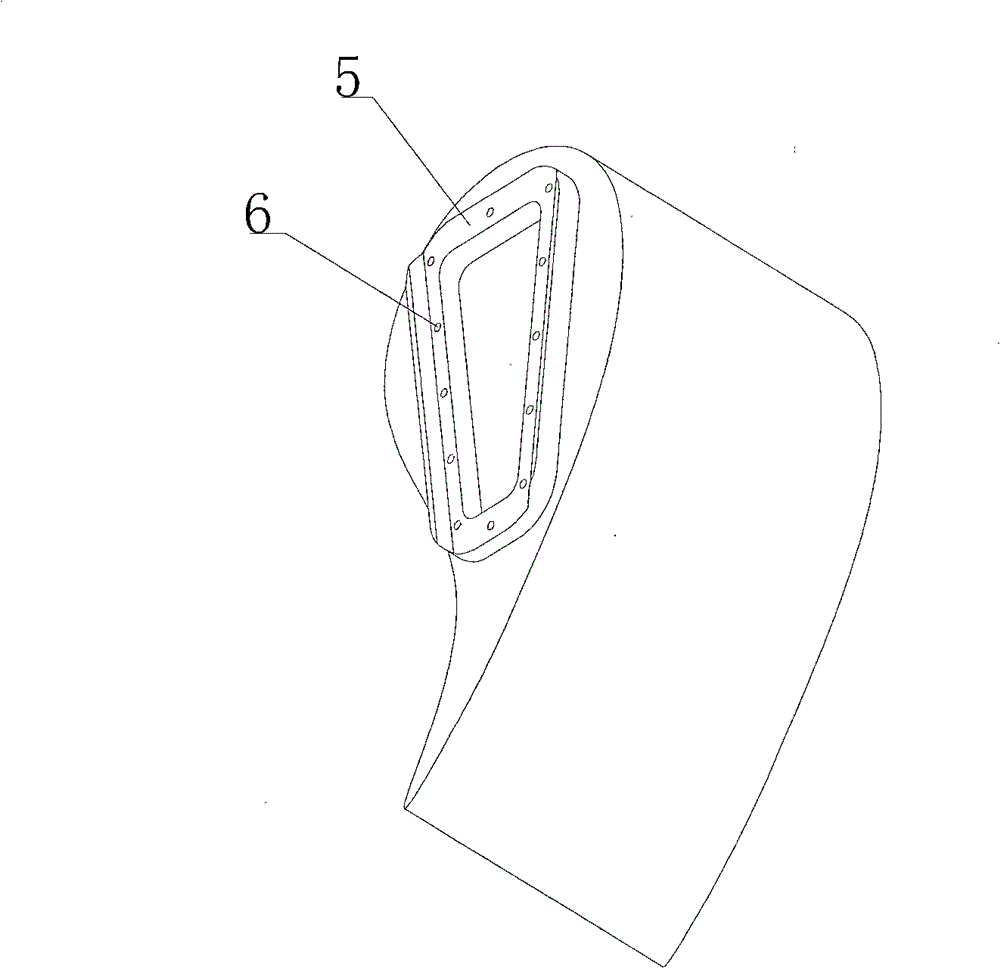

Substrate fermentation device with interlayer, gas chimneys and movable bottom doors

InactiveCN108017422ASimple processIntensive low-carbon fermentationBio-organic fraction processingOrganic fertiliser preparationNatural ventilationSemi automatic

The invention discloses a substrate fermentation device with an interlayer, gas chimneys and movable bottom doors. The device is of a steel grille frame structure and comprises a frame opening (1), aframe body (2) and a frame bottom (3). The device is characterized by being further provided with the interlayer (4), the gas chimneys (5) and the movable bottom doors (6); the interlayer (4) is double-sided galvanized steel wire mesh plates arranged in the middle of the device at spacing of 50-80 mm, the device is divided into 2-4 bins, and a hollow ventilation layer is formed; the gas chimneys (5) are arranged in the divided bins, and 4-6 hollow permeable cylinder holes penetrating the frame opening (1) and the frame bottom (3) are formed; the two movable bottom doors (6) are arranged at thebottom of the device and facilitate discharging. According to the device, the mesh plate hollow interlayer and the gas chimneys are adopted for natural ventilation, one-time turnover-free static fermentation and semi-automatic discharging of / at the movable bottom plates are achieved, and use is convenient; the device is made of a steel material, has reasonable structure and long service life, canbe stacked in multiple layers, saves fermentation sites, and is especially suitable for fermentation treatment of industrial solid waste raw materials by substrate production enterprises.

Owner:江苏兴农基质科技有限公司

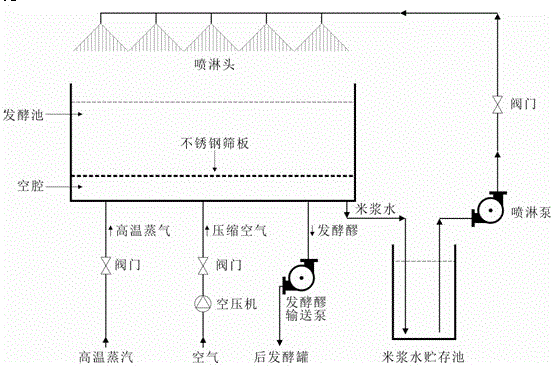

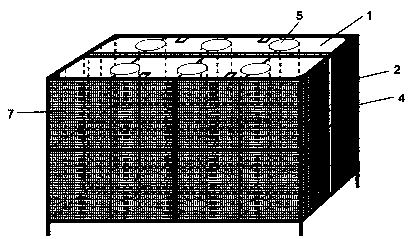

Energy-saving and water-saving yellow wine production device

InactiveCN106635636AEmission reductionReduce production water consumptionAlcoholic beverage preparationWater savingChemical oxygen demand

Traditional yellow wine production relates to extremely complicated technical processes such as rice soaking, rice steaming, cylinder filling, yeast adding, fermentation, filtering, boiling and ageing, during which large amounts of labor is required for transporting materials from one container to another, the rice soaking process can produce a large amount of rice milk, resulting in a COD (chemical oxygen demand) up to 53000 mg / L, accordingly waste of crops and environmental pollution are caused. Therefore, the invention relates to an energy-saving and water-saving yellow wine production device integrating rice soaking, rice steaming and fermentation. The energy-saving and water-saving yellow wine production device is characterized in that 1) rice soaking is performed in a cycling spraying manner, which, compared with traditional flooding type rice soaking manners, can save water by more than 1 / 2, and meanwhile, rice milk can be completely utilized to achieve zero discharge; 2) rice soaking period is shortened to 1-2 hours, so that losses of raw material rice during rice soaking can be significantly reduced; 3) rice soaking, rice steaming and fermentation are performed in situ through one device, so that material conveying strength can be significantly reduced, energy sources, labor, facilities and rice soaking and washing water can be saved, and meanwhile production lands can also be saved.

Owner:绍兴市抱龙山酒业有限公司

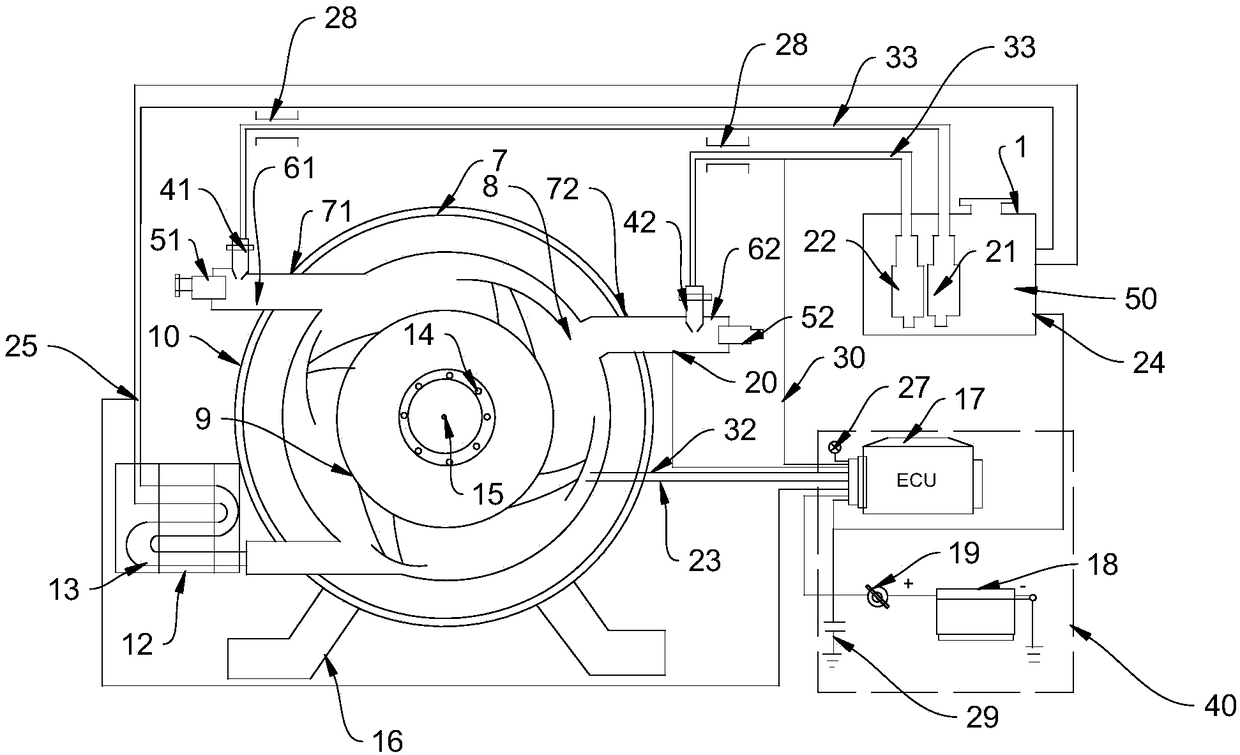

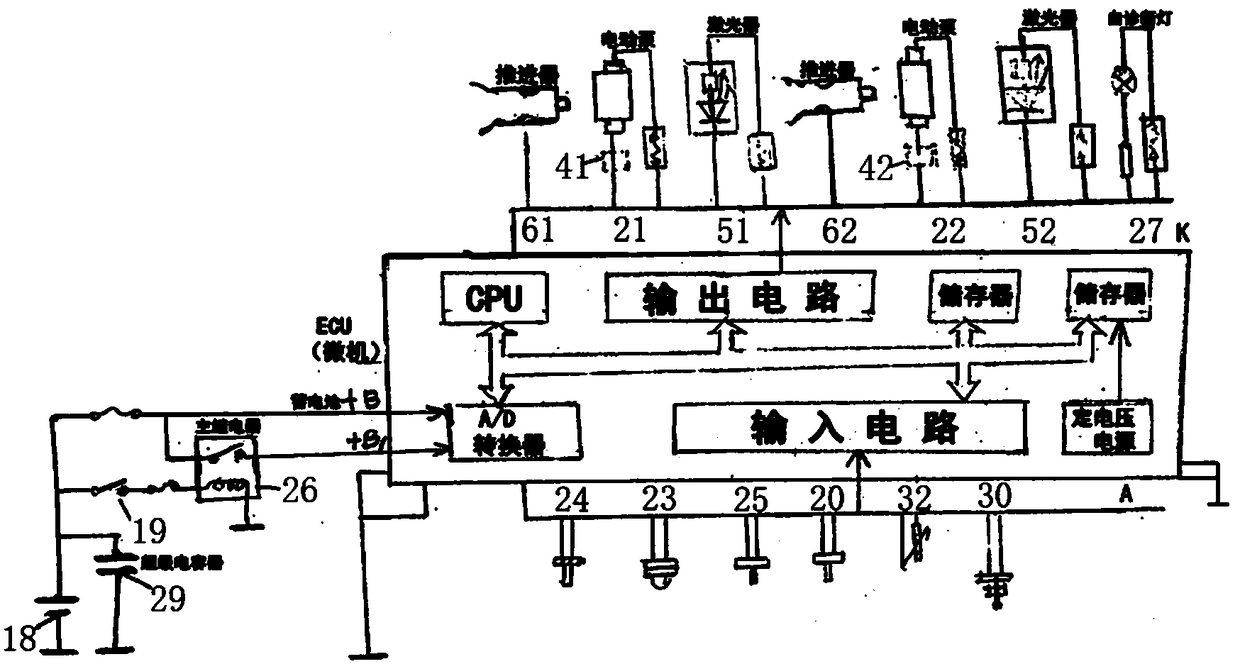

Rotary impeller engine

InactiveCN108412671ASave the workshopAvoid emissionsHydro energy generationSafety/regulatory devicesImpellerPropeller

The invention discloses a rotary impeller engine which comprises a liquid supply device, a controller and an engine body. The liquid supply device and the controller are connected with the engine body. The engine body comprises an engine shell, a rotary impeller is installed in the shell, and the shell is provided with at least one liquid inlet and liquid outlet, a direct injection propeller is arranged on the liquid inlet, a semiconductor laser device and a pump injector are installed on the direct injection propeller, the liquid supply device is connected with the engine shell through the pump injector, and a magnetizer is arranged between the liquid supply device and the pump injector. The rotary impeller engine can save equipment, workshops, materials, labor and time, is low in cost and high in yield, and can be put on the market conveniently. The problem that a large amount of pollutant is discharged to pollute environment and ecology is avoided, the purposes of high quality, highefficiency and high output power can be achieved, and an updated power source with the wide sustainable market development prospect is achieved.

Owner:王忠和

PUR and glue point transfer compounding process

PendingCN112848629AIncrease productivityReduce labor costsLamination ancillary operationsLaminationYarnManufacturing engineering

The invention belongs to a PUR and glue point transfer compounding process in the textile field. The PUR and glue point transfer compounding process comprises the steps of front fabric expanding, gluing, scutching, rear fabric expanding, yarn separating, scutching, deviation rectifying, large drying cylinder high-temperature drying and pressing, water cooling under the traction effect, edge cutting and floating roller adjusting and rolling. The front fabric and the rear fabric are independently operated and summarized, and two modes of automatic edge alignment double-roller surface rolling and swing arm surface friction center rolling are adopted, so that the production efficiency can be greatly improved, and the labor cost is saved.

Owner:江苏鑫利龙轻化设备有限公司

Manufacture method of stainless steel screw

InactiveCN103133473AHas self-tempering propertiesImprove mechanical propertiesScrewsRebarMechanical property

A manufacture method of a stainless steel screw includes the following steps: (1) forging, (2) carburization, (3) welding, and (4) quenching. According to the method, a low-carbon steel bar or a low-carbon alloy steel bar is used for treatment, and the low-carbon steel bar or the low-carbon alloy steel bar has the advantages of self tempering and high mechanical performance, replaces a medium-carbon alloy steel bar, has the same high mechanical performance and reaches the standard after the treatment and is bluing. Tempering is eliminated, equipment, electricity and plants are saved, an existing production line is improved, and cost is saved. The low-carbon steel bar or the low-carbon alloy steel bar is directly used along with a hot-rolled steel bar and treated through waste heat of the steel bar, steel is saved for construction engineering, and economic benefits are remarkable.

Owner:江苏亚洲气体设备有限公司

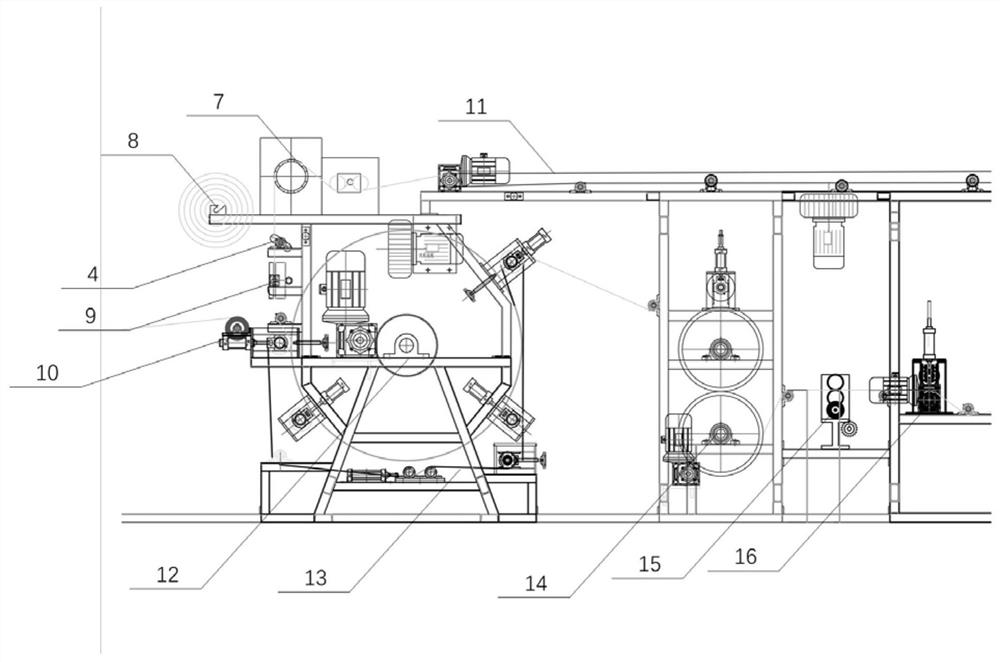

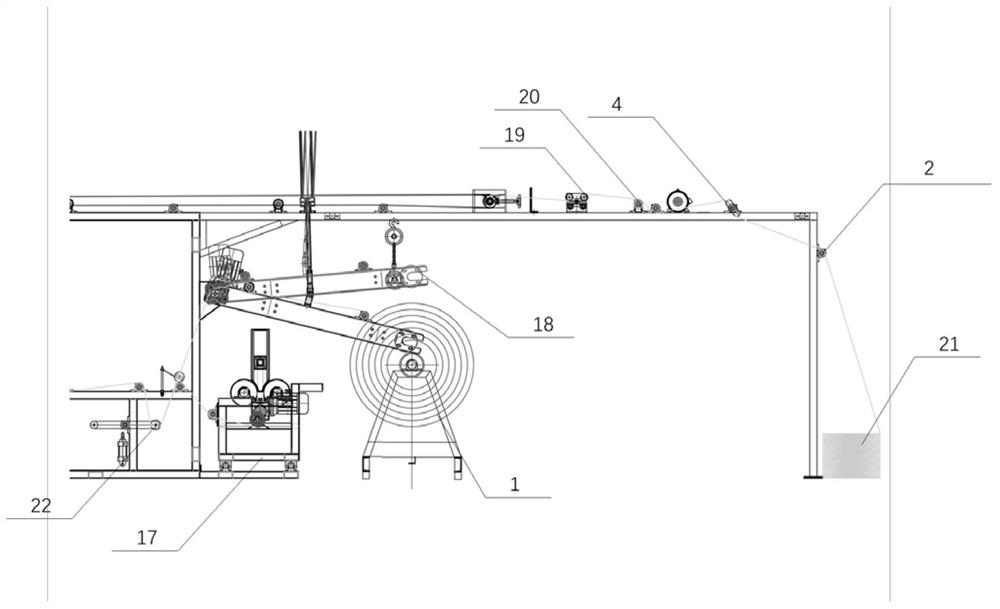

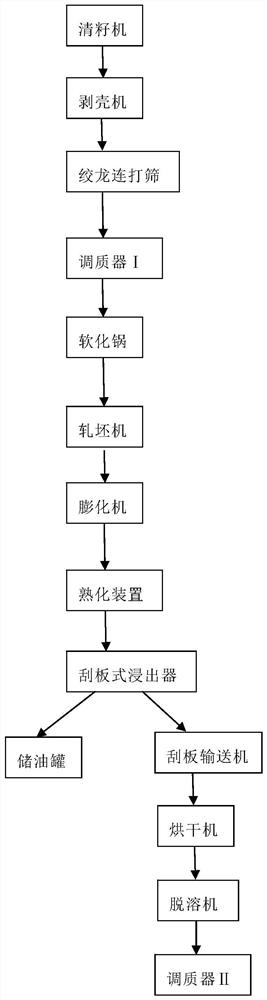

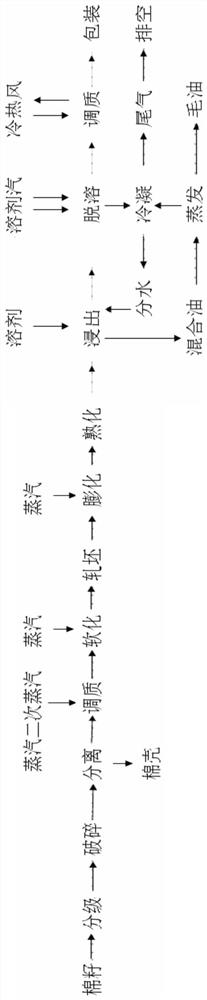

Cottonmeal processing system and technology

The invention provides a high-quality puffed cottonseed meal processing system and process. The cottonmeal processing technology comprises the following steps: cottonseed selection, shelling, tempering and softening, puffing, curing, leaching, desolventizing and re-tempering. The cottonseeds enter a puffing machine after tempering and softening and are puffed under a high-pressure condition, low-temperature extraction and desolventizing are performed after puffing, and natural active substances in the cottonseeds are retained greatly. The cottonseed meal produced by the technology is good in condition, light in color, low in free gossypol content (below 500 ppm), high in water-soluble nitrogen index (above 75%) and low in protein denaturation, original ecological protein is reserved as much as possible, the purpose of reducing the toxicity of the cottonseed meal is achieved, the cottonseed meal addition amount and the unit cottonseed meal absorptivity in the feed industry are improved, and the effectiveness of the cottonseed meal is enhanced.

Owner:刘庆锋 +1

Matrix fermentation device with interlayers, chimneys and movable bottom doors, and application

InactiveCN107805093ASimple processIntensive low-carbon fermentationBio-organic fraction processingOrganic fertiliser apparatusSemi automaticEngineering

The invention discloses a matrix fermentation device with interlayers, chimneys and movable bottom doors, and application thereof. The device is of a steel barrier type frame structure, which is formed by a frame opening (1), a frame body (2) and a frame bottom (3). The device is characterized by further comprising the interlayers (4), the chimneys (5) and the movable bottom doors (6); the interlayers (4) are double-sided zinc coating steel wire mesh plate at intervals being 50 to 80mm arranged in the middle of the device, divide the device into 2 to 4 silos, and form hollow aeration layers; the chimneys (5) are arranged in the separated silos and are 4 to 6 hollow ventilated cylindrical holes penetrating through the frame opening (1) and the frame bottom (3); the movable bottom doors (6)are arranged on the bottom part of the device and comprise two movable doors so as to be convenient to discharge. The device adopts the mesh plate hollow interlayers and the chimneys to naturally ventilate; when the device is applied to carry out matrix fermentation, one-time stirring-free static fermentation and semi-automatic discharging through the movable bottom plates can be realized, so thatthe device is convenient to use and good in effect. The device is made of steel materials so as to be reasonable in structure and long in service life, and can be multilayer stacked, so that a fermentation space is saved, and the device is particularly suitable to be applied to industrial solid waste raw material fermentation treatment carried out by matrix production enterprises.

Owner:江苏兴农基质科技有限公司

A method for comprehensive utilization of plant ash in biomass power plants

ActiveCN102744238BReduce manufacturing costIncrease profitSolid waste disposalAlkali metal sulfite/sulfate purificationSlagSorbent

Owner:NANJING TECH UNIV

Semi-artificial cultivation method for amanita parvipantherina

InactiveCN103004456BArtificial culture possibleEasy to operateHorticultureBiotechnologyChemical synthesis

The invention relates to a semi-artificial cultivation method for amanita parvipantherina, belonging to the technical field of large fungus culture. The semi-artificial cultivation method is characterized in that a large number of hyphae which are obtained in a laboratory through solid culture are directly inoculated into an outdoor natural habitat; and the hyphae are grown and developed by adding a growth promotion substance to finally grow fruiting bodies. Mycelia are directly induced to fruit by using natural growth conditions; and the method has the advantages of easiness in operation, original ecology, no pollution, energy saving, capability of saving a factory building and the like, and is a more ideal culture mode at present. The amanita is a special and precious large economic fungus, has high value and a wide application range, has potential application prospect in the fields of developing new specific medicines such as anti-tumor medicines, anti-bacterial and anti-viral medicines, sedatives or narcotic and the like, is difficult to develop and apply due to the problems such as valuable and rare resource, difficulty in artificial domestication and inactivity of chemical synthetic products of toxin up to now, is used as a peptide toxin of a biochemical reagent and is worth over one hundred thousand dollars every gram. The fact that the hyphae are difficultly developed into the fruiting bodies under the culture conditions is a key factor for restricting the artificial culture; and taking the amanita parvipantherina for instance, certain breakthrough is realized aiming at the problem, so that the artificial culture of the parvipantherina becomes possible, and conditions are created for sustainable development and utilization of the resource.

Owner:YUNNAN UNIV

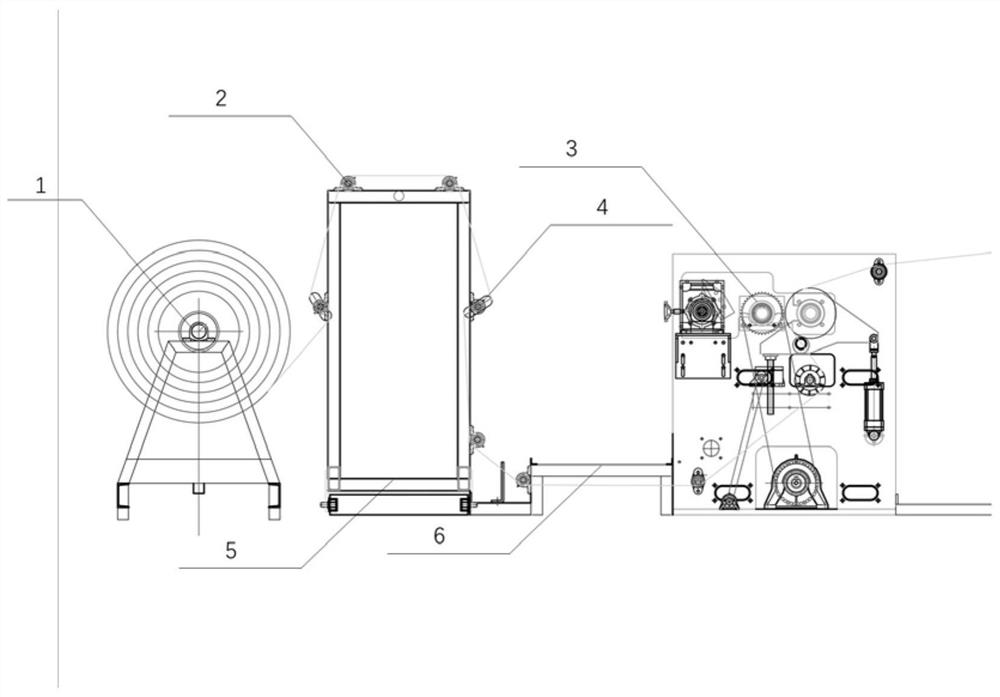

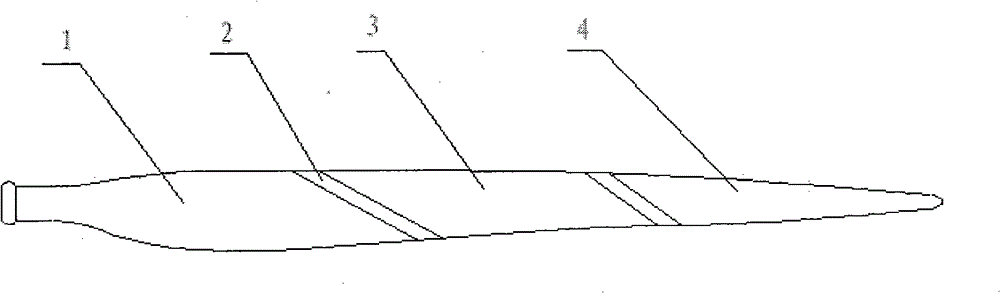

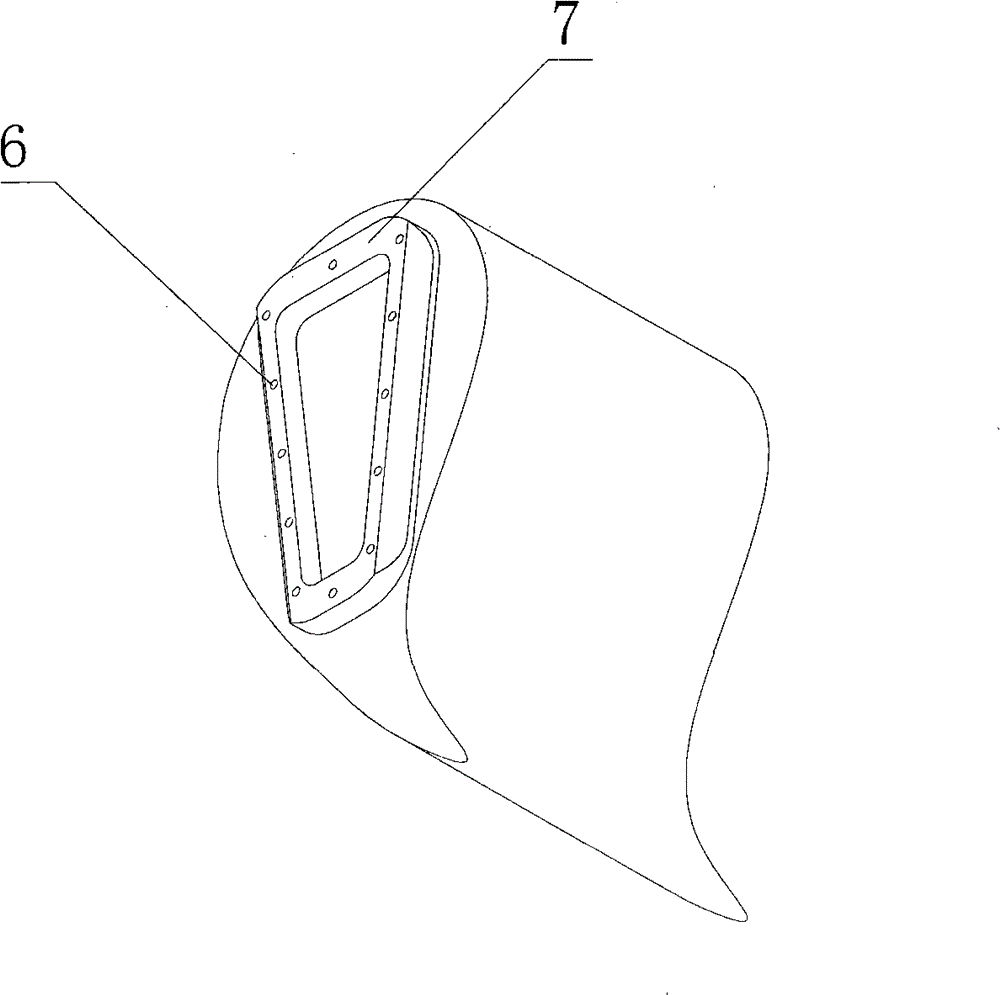

Sectionalized-assembly type fan blade and manufacturing method thereof

InactiveCN102011711BSave the workshopEasy to assembleFinal product manufactureWind energy generationPulp and paper industryFan blade

The invention discloses a sectionalized-assembly type fan blade and a manufacturing method thereof. The fan blade comprises a blade body, wherein the blade body is at least divided into two sections which are respectively provided with an abutting surface; and the abutting surfaces between adjacent sectionalized blade bodies are fitted and connected. The invention has the beneficial effects that sectionalized manufacture can be conducted without larger dies, thereby saving workshop cost and manufacturing cost; sectionalized transport and storage can be realized, thereby being more convenient;and each sectionalized-assembly is more convenient and the assembly is firmer, thereby being safe to use.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

Blended pulverized coal combustion control device and method

InactiveCN103234215BBurn completelyImprove combustion efficiencyCombustion regulationLump/pulverulent fuel feeder/distributionCombustion systemThermodynamics

Owner:KUNMING UNIV OF SCI & TECH

Application method of mvr heat pump evaporation salt production in multi-effect vacuum salt production technology

ActiveCN113577799BAdvanced technologySimple structureHeat pumpsEvaporator accessoriesAir preheaterProcess engineering

Owner:SHANDONG CAIYANGZI SALTWORKS

A kind of pure polyphenylene sulfide fiber high-grade electrical insulating paper and its preparation method

Owner:SICHUAN TEXTILE SCI RES INST

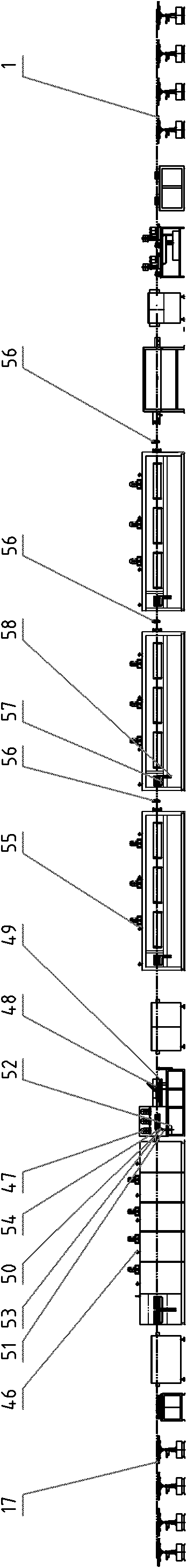

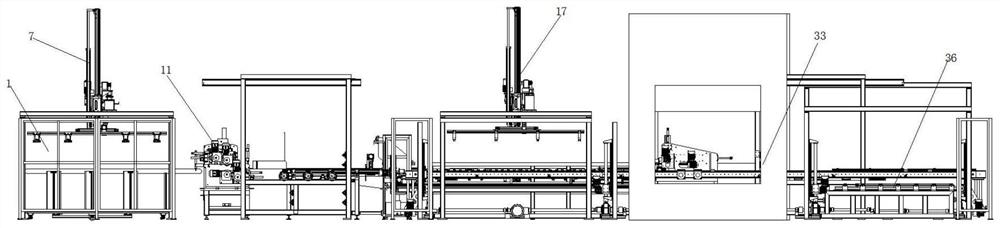

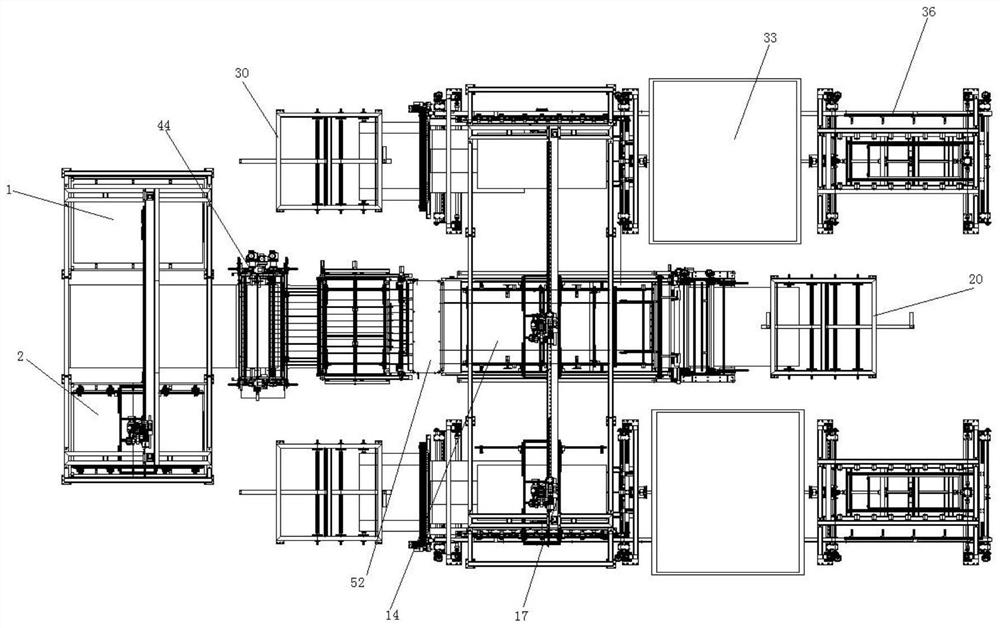

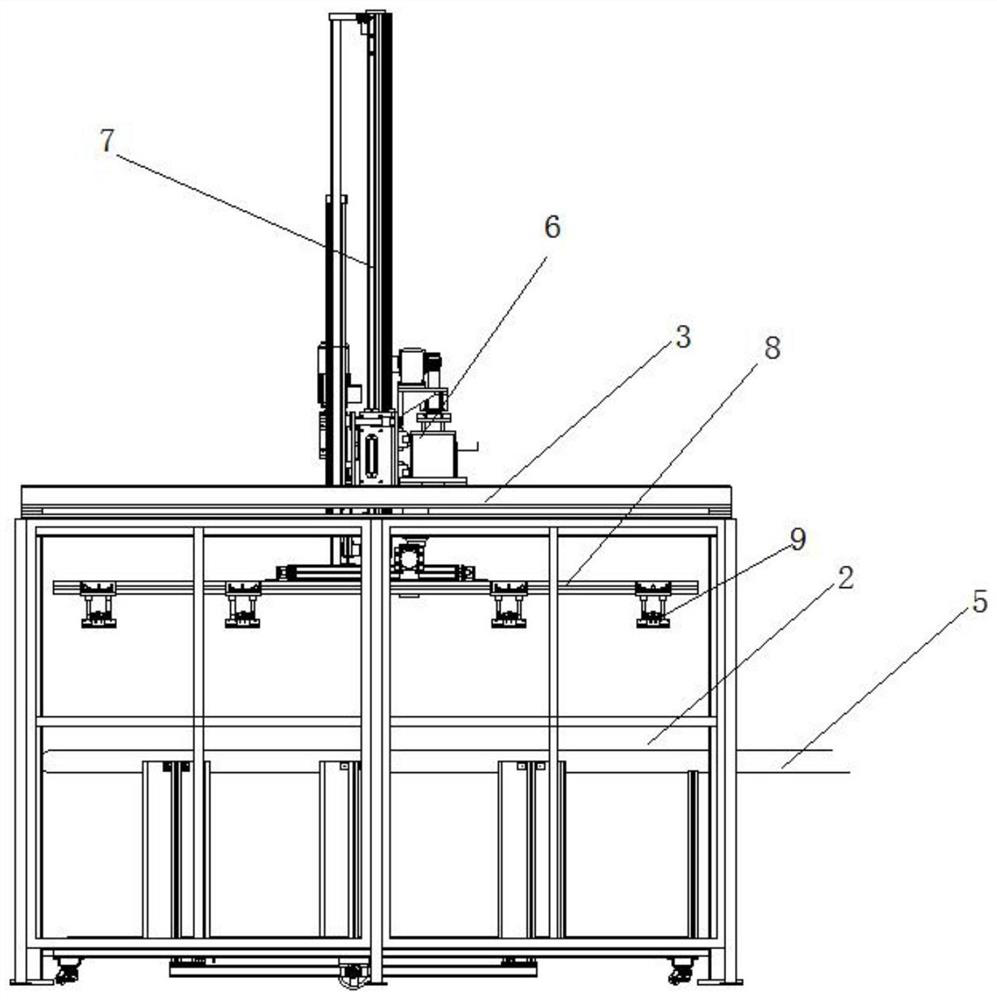

Composite production line of automobile top interior trim assembly

ActiveCN114683669ASave the workshopSave landLamination ancillary operationsLaminationCommon lineManufacturing line

The invention relates to a composite production line of an automobile top interior trim assembly. Comprising a set of formed skeleton transferring stations, pressing units arranged corresponding to the formed skeleton transferring stations, auxiliary material feeding stations connected with the pressing units, roll material cutting stations connected with the auxiliary material feeding stations, a double-station needling feeding structure connected with the rear ends of the roll material cutting stations and a middle common line adjusting structure. The production line has the advantages that workshops and land can be saved, and the productivity of one-span workshop can reach that of two-span workshops in a traditional scheme; the production efficiency is twice that of a traditional production line, only one span of plants are occupied, land and plants are reduced, and the investment cost is greatly reduced. Under the condition that stations are not increased, the problems of simultaneous composite production of two products and composite production of two products A and B according to a specified proportion are solved. The industrial effect is obvious, the productivity is high, and the practicability is very good.

Owner:昆山隆昌车业有限公司

A power island layout structure of a combined cycle power plant with one dragging one multi-shaft gas turbine extraction condensing back pressure unit

ActiveCN105822098BReduce areaSave the workshopCombined combustion mitigationIndustrial buildingsTransformerCondensate pump

A power island layout structure of a combined cycle power plant with a one-to-one multi-shaft gas turbine extraction-condensation back-pressure unit includes: two gas turbines are arranged in an outdoor open air, two waste heat boilers are arranged in a mirror-symmetrical arrangement, and a steam turbine is arranged in a steam engine room Indoor and the center line of the steam turbine and the center line of the gas turbine are kept parallel; the steam turbine room adopts a combined workshop with unequal column spacing, and the column spacing of the workshop at the side of the back pressure unit is 5 meters, 8 meters, and 5 meters; They are 3.9 meters and 7.9 meters respectively; the maintenance span is cancelled, the back pressure unit and the condensation extraction unit are respectively set with independent manholes of 4.91 × 9 meters and 6.15 × 9 meters, correspondingly equipped with two 32t / 5t and 75t / 20t vehicles. The lower chord elevation of the powerhouse is 22.73m; the PC and MCC of the main powerhouse are arranged on the 0m floor and the middle floor respectively, and the generator outlet is set on the 3.9m floor. electrical room.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

Damp-proof film coating agent and salt film coating method

InactiveCN105685938AImprove liquidityEvenly dispersedFood coatingInorganic compound food ingredientsSolventStearic acid

The invention belongs to the technical field of film coating and discloses a damp-proof film coating agent. The damp-proof film coating agent comprises components in parts by mass as follows: a film forming agent and a solvent in a ratio being 1:(2-10), wherein the film forming agent is selected from one or more of stearic acid, beewax, collodion, ethyl cellulose and prolamine; the solvent is selected from one or more of ethanol, acetone, propane, ethyl ether and dimethyl ether. The preparation method of the damp-proof film coating agent comprises steps as follows: the raw materials in the formula ratio are taken, mixed and stirred until the film forming agent is dissolved completely, and the mixture is uniformly stirred. The invention further discloses a salt film coating method. The salt film coating method comprises steps as follows: the film coating agent and the solvent in the formula ratio in Claim1 are taken, mixed and stirred until the film forming agent is completely dissolved, the mixture is uniformly stirred, and a film coating solution is obtained; (2), salt and the prepared film coating solution are uniformly stirred, mixed and air-dried. The damp-proof film coating agent and the salt film coating method have good application prospect in the aspect of film coating damp-proof processing of low sodium salt and granules containing magnesium sulfate, potassium chloride, sodium chloride, calcium chloride and the like.

Owner:卢广荣 +1

Virus split deactivation method for human influenza virus split vaccine

ActiveCN102614508BSolve the aggregation problemImprove uniformityInactivation/attenuationAntiviralsHuman influenzaAvian influenza virus

Owner:长春生物制品研究所有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com