Rotary impeller engine

An engine and rotary wheel technology, applied in the direction of engine components, machines/engines, impact engines, etc., can solve the problems of engine environmental pollution, low thermal efficiency, high manufacturing cost, etc., and achieve the effect of saving workshops, high output power, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

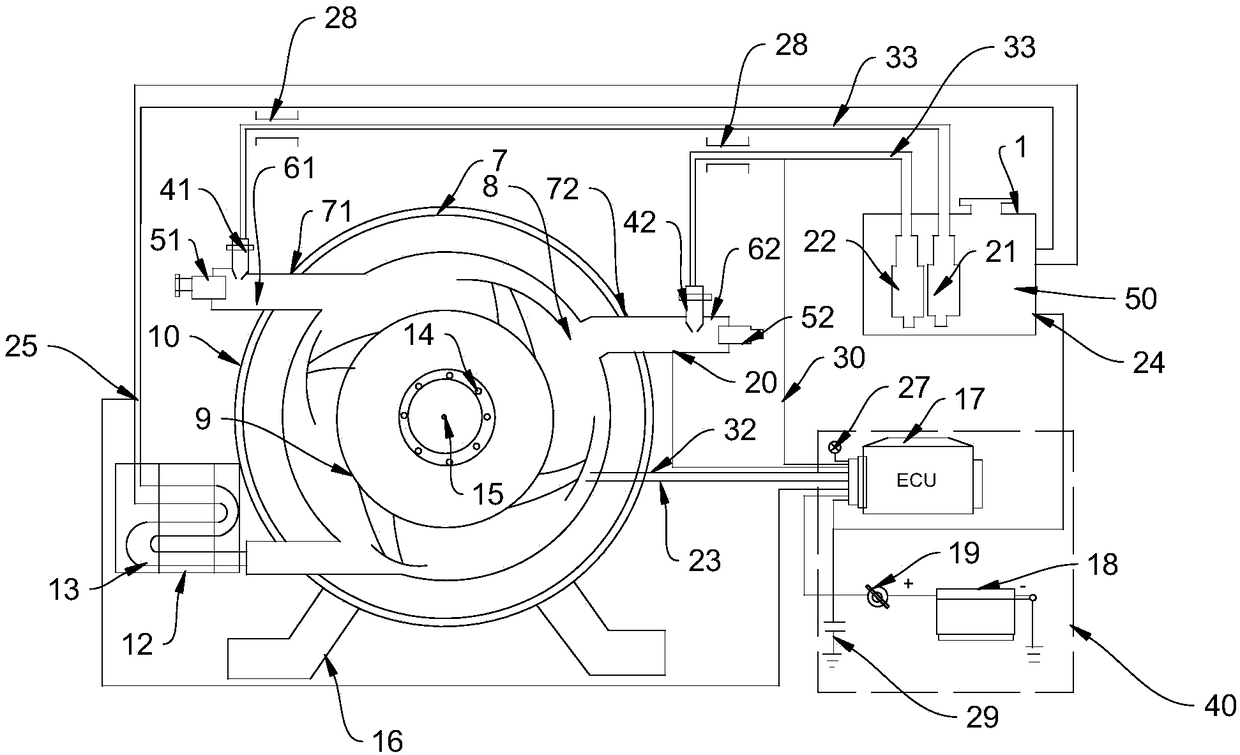

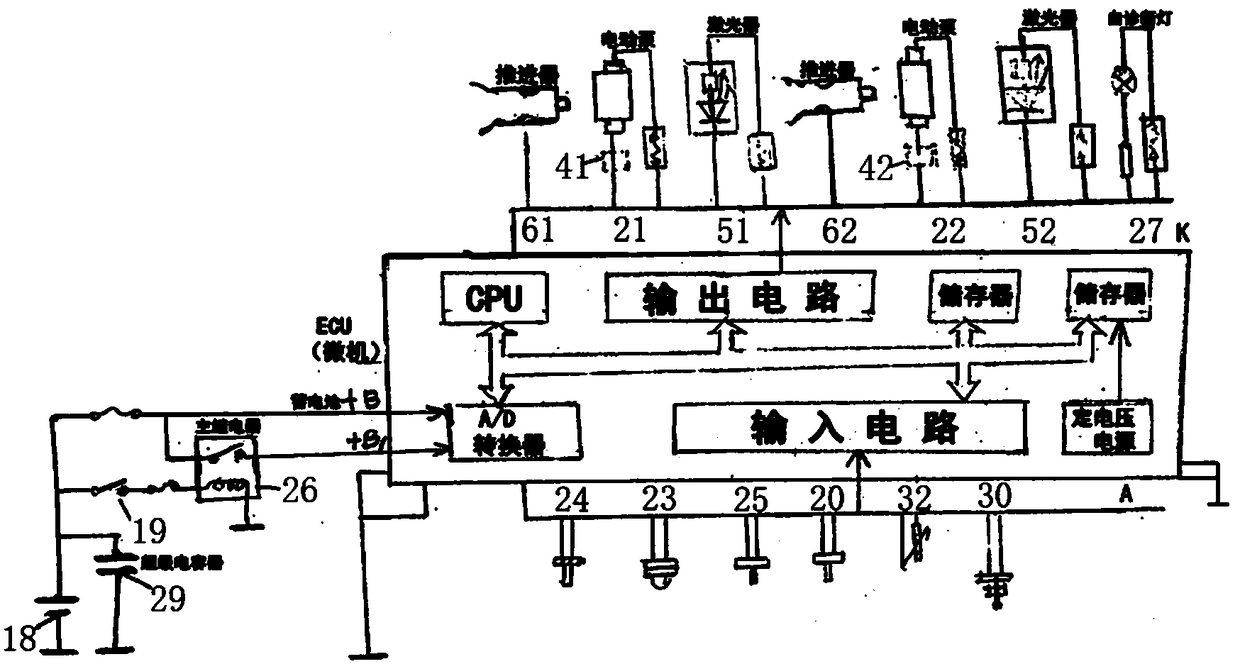

[0024] Such as figure 1 As shown, the rotary wheel engine of the present invention includes a liquid supply device 50, a controller 40, and a body 10, and the liquid supply device 50 and the controller 40 are connected to the body 10 respectively; A rotating impeller 9 is installed, and the center of the rotating impeller 9 is set as a rotating shaft 15, through which the power is output to the outside. mouth and liquid outlet; a direct injection propeller 41 is provided at the liquid inlet, a semiconductor laser 51 and a pump injector 41 are installed on the direct injection propeller 61, and the liquid supply device 50 is connected with the casing 7 through the pump injector, A magnetizer 28 is provided between the liquid supply device 50 and the pump injector 41; there is a propellant in the liquid supply device 50, and the propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com