A kind of pulp mixing process technology

A pulp mixing and process technology, applied in pulp beating/refining methods, papermaking, paper recycling, etc., can solve the problem of high energy consumption, achieve the effects of simplification of chemical systems, realization of costs, and reduction of the number of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

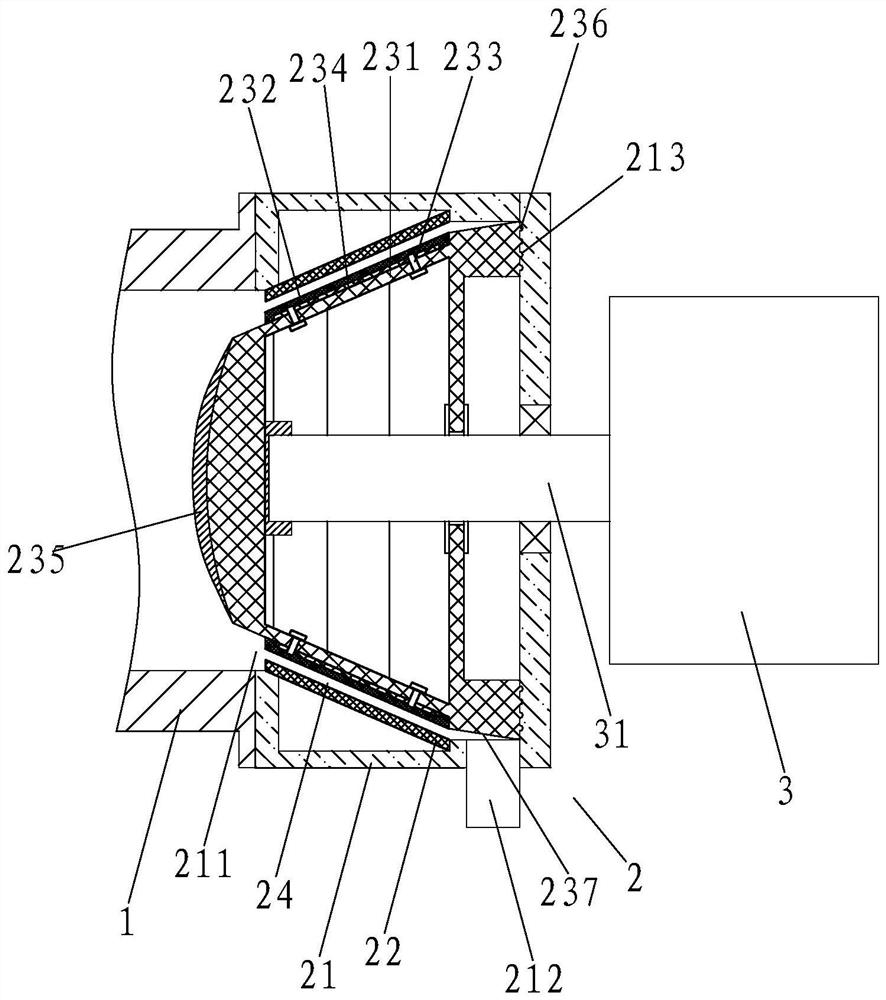

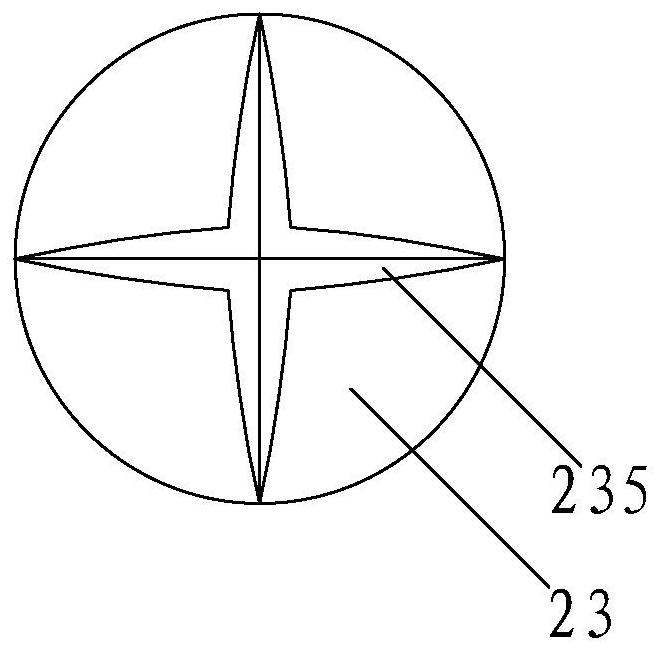

[0030] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

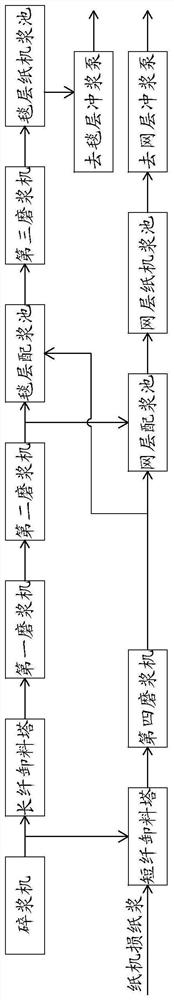

[0031] refer to figure 1 , the present embodiment provides a pulp blending process technology, including the following steps:

[0032] In the first step, the long fiber material enters the pulper for pulping, and then the long fiber is output to the long fiber discharge tower, and the paper machine broke pulp is output to the short fiber discharge tower;

[0033] In the second step, the long fibers stay in the long fiber discharge tower for 65-216 minutes and then enter the first refiner and the second refiner in turn, and then output to the felt layer mixing pool and the mesh layer mixing pool respectively;

[0034] In the third step, the short fibers stay in the short fiber discharge tower for 35-116 minutes and then enter the fourth refiner, and output to the felt layer mixing pool and the mesh layer mixing pool;

[0035] Step 4: After mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com