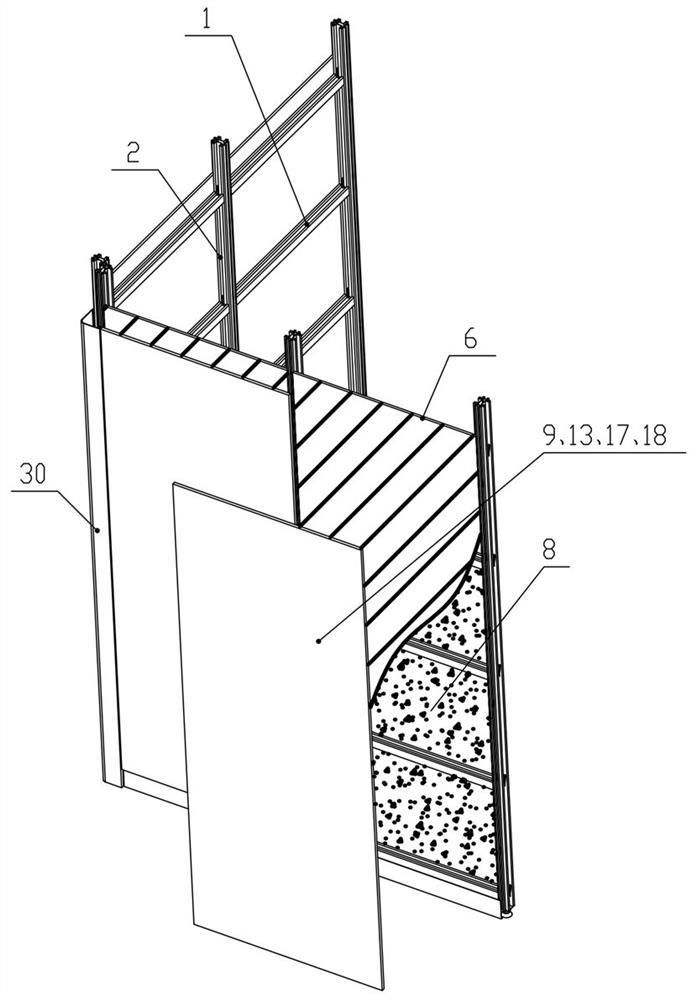

Multifunctional assembly type cold-bent light steel keel frame wall structure

A light steel keel and wall structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of inconvenient disassembly, lack of overall strength, and high personnel requirements, improve surface flatness, and achieve recyclability. , The effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

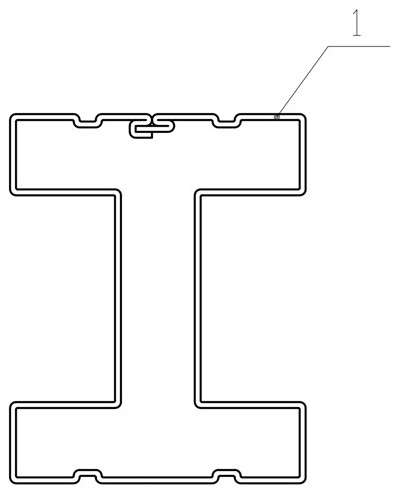

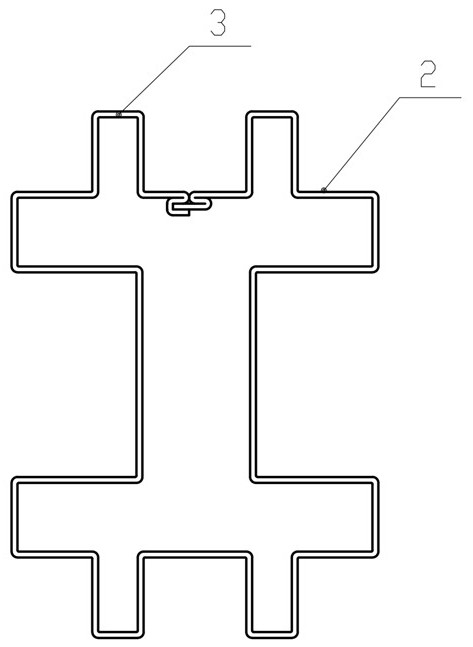

[0046] Embodiment one: if Figure 13 , Figure 14 , Figure 15 As shown, the decorative layer is a convenient hanging wallboard 9, wallboard hooks 10 are arranged on both sides of the convenient hanging wallboard 9, and wallboard hanging hooks 10 are arranged on the top surface of the functional protrusion 3 of the vertical keel 2. Mounting hole 11, the wall panel hook 10 falls in the wall panel hanging hole 11 to realize the convenient hanging of the wall panel 9 on the vertical keel 2; a rectangular sealing strip 12 is clamped between the functional protrusions 3, and the rectangular sealing The upper surface of the bar 12 is offset against the outer edge flanging of the portable hanging wallboard 9 . After the keel wall is installed, the keel hanging hole 5 on the vertical keel 2 can perfectly cooperate with the finished modularized convenient hanging wall panel 9, so that the keel frame can be vertically erected, and the hanging plate can also be installed synchronously ...

Embodiment 2

[0047] Embodiment two: if Figure 16 , Figure 17 As shown, the decorative layer is a hanging panel 13, and the hanging panel 13 can be made of inorganic pre-coated board, glass, resin board or marble. A panel horizontal hook 14 is fixedly arranged on the inner surface of the hanging panel 13, and a panel horizontal hanging seat 15 is fixedly arranged at a corresponding position on the outer surface of the inorganic panel 6, and the panel horizontal hanging seat 15 falls into the panel horizontal hook 14 to realize the hanging panel 13 for hanging on the inorganic panel 6, a cushioning pad 16 is arranged on the side of the panel transverse hanging seat 15, and the cushioning pad 16 is offset against the inner surface of the hanging panel 13.

Embodiment 3

[0048] Embodiment three: as Figure 18 As shown, the decorative layer is a veneer decorative board 17, and the veneer decorative board 1 and the inorganic panel 6 are directly attached by glue. After the keel wall is installed, there is no need for secondary treatment on the overall wall surface. It can be directly brushed with all-purpose glue, pasted with inorganic pre-coated board and resin board. Since the strength of the keel is better than that of the general square tube keel, the surface smoothness can be very good ensure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com