Reserved hole anti-leakage treatment process and wall-penetrating cantilever scaffold profile steel

A technology of overhanging scaffolding and reserving openings, which is applied to scaffolding supported by housing structures, housing structure support, housing structure support, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

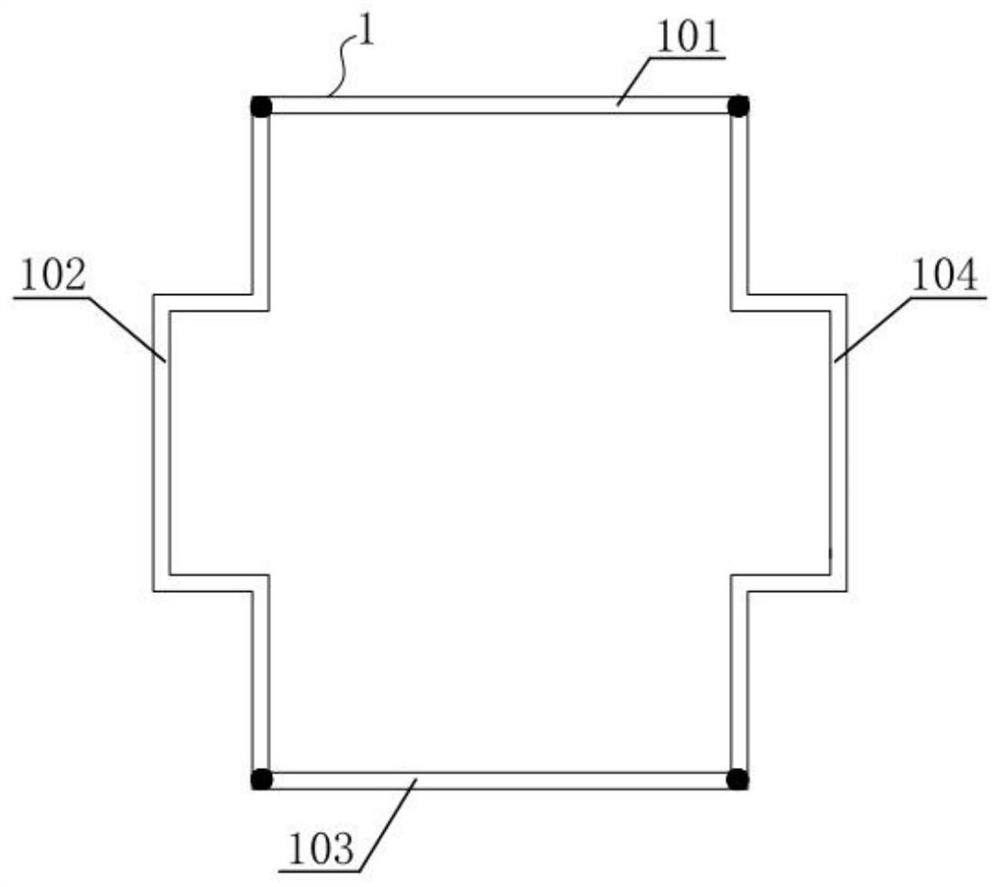

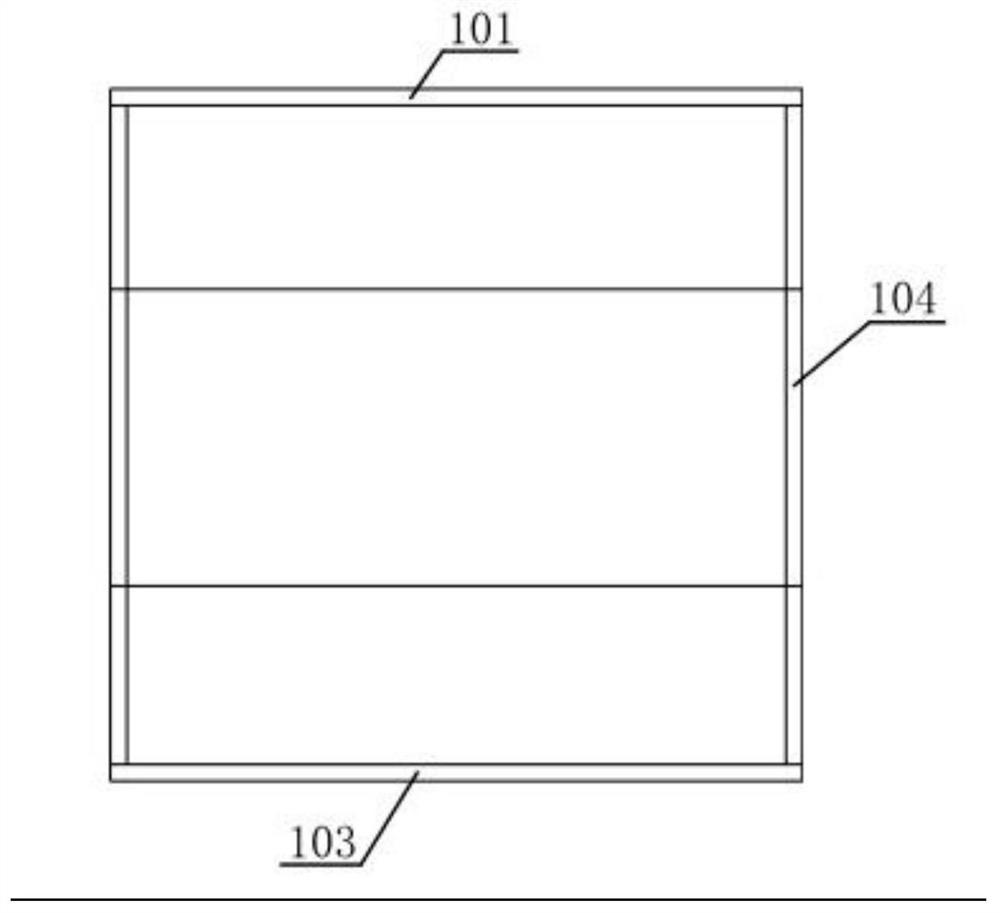

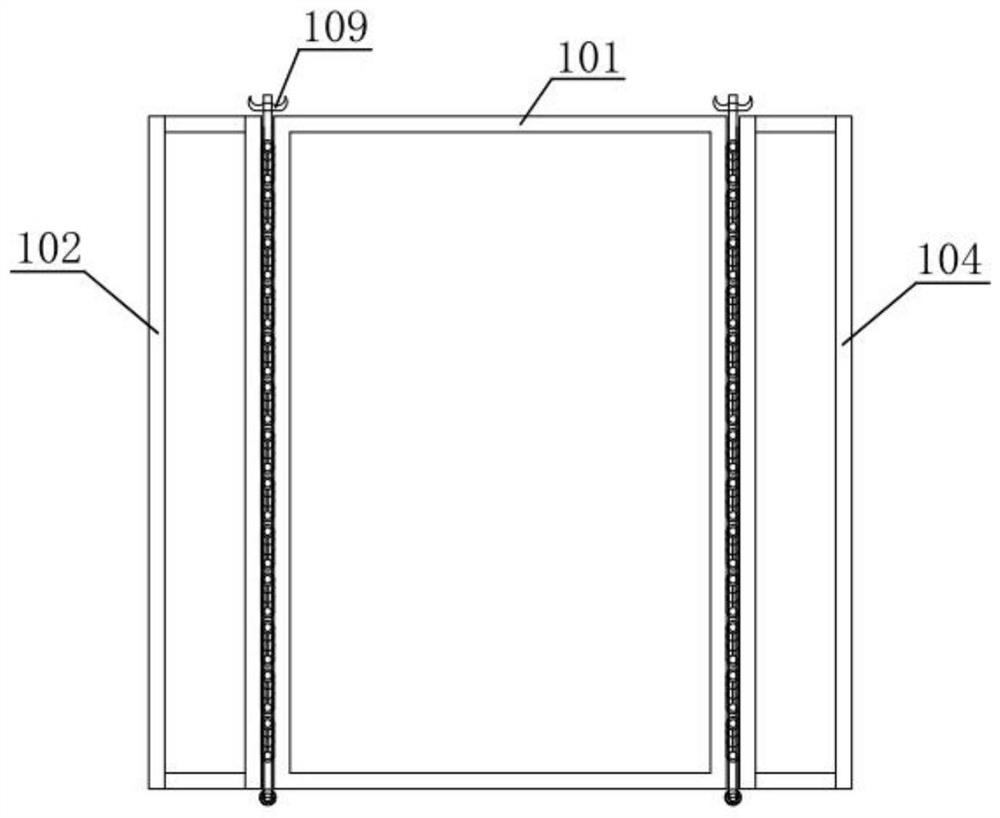

[0038] Cantilevered scaffold steel through the wall, such as Figure 1-3 As shown, the cantilevered scaffold section steel 1 through the wall is a frame structure surrounded by an upper branch 101 , a left branch 102 , a lower branch 103 and a right branch 104 .

[0039] In this embodiment, the upper branch 101 and the lower branch 103 are rectangular frame structures, and the left branch 102 and the right branch 104 are provided with protrusions, so that the cantilevered scaffold steel 1 formed by enclosing the wall is Cross frame structure.

[0040] It should be noted that the cantilevered scaffold section steel 1 through the wall is not limited to the cross frame structure, and in other embodiments, it can also be a rectangular frame structure or other shapes, because the cantilevered scaffold section steel 1 through the wall needs to be pre-embedded To the reserved hole, therefore, the shape and size of the cantilevered scaffold steel 1 through the wall need to be adjuste...

Embodiment 2

[0046] Concrete block molds for making precast concrete such as Figure 5-7 As shown, the concrete block mold 2 is made up of an upper mold 201 and a lower mold 202, as Figure 5 As shown, the upper mold 201 has a convex structure, and the lower mold 202 is provided with a protrusion opposite to the convex structure of the upper mold 201, so that the concrete block mold 2 has a cross frame structure.

[0047] The concrete block mold 2 is also not limited to the cross frame structure of the present embodiment, and it can be adjusted according to the shape of the reserved hole.

[0048] In order to facilitate the removal of the precast concrete block, the concrete block mold 2 of this embodiment is a detachable structure, that is, the upper mold 201 and the lower mold 202 are detachably connected, and the detachable structure is the same as that in the first embodiment.

[0049] In this embodiment, the upper mold 201 is provided with a first convex line 203, the first convex line...

Embodiment 3

[0052] The anti-seepage treatment process for reserved openings includes the following steps:

[0053] (1) if Figure 10 As shown, the original wall structure is provided with a reserved hole 4, and the wall-mounted cantilevered scaffold steel 1 is pre-buried at the reserved hole 4, and the wall-through cantilevered scaffold steel 1 is set close to the wall of the reserved hole 4;

[0054] (2) make prefabricated concrete block 3 according to the shape and size of reserved hole 4, the size of prefabricated concrete block 3 is 20mm smaller than the size of reserved hole 4, but not limited to this, specifically can be between 15-25mm Adjust; Prefabricated concrete block 3 specifically adopts the concrete block mold 2 in embodiment 2 to carry out the making of prefabricated concrete block 3, and maintains after prefabricated concrete block 3 demoulding;

[0055] (3) After the overhanging scaffolding through the wall is removed, if Figure 11 with 12 As shown, remove the cantile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com