Belt baffle structure of snow sweeper

A baffle structure and technology for snow plows, applied in belt/chain/gear, snow surface cleaning, mechanical equipment, etc., can solve the problems of poor rigidity of belt baffles, affecting the normal operation of snow plows, and belt failure, etc. The effect of reducing friction, reducing deformation and misalignment, and extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

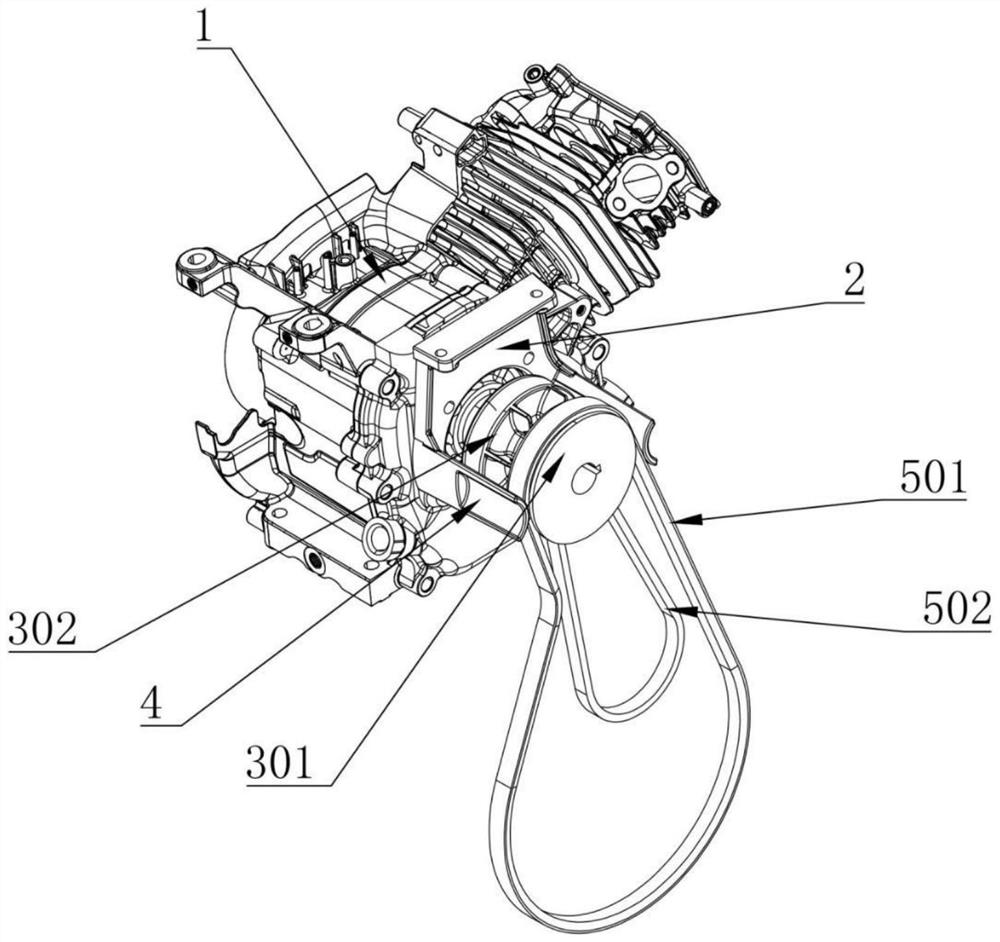

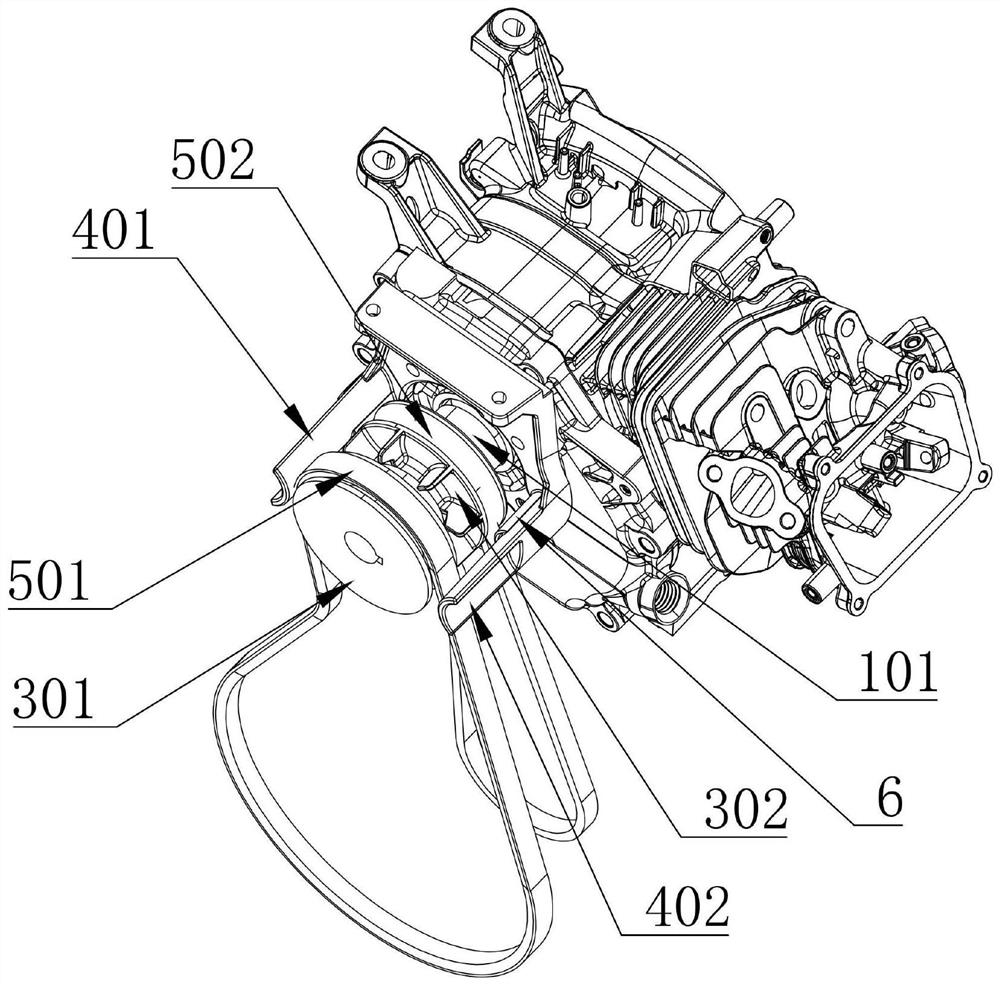

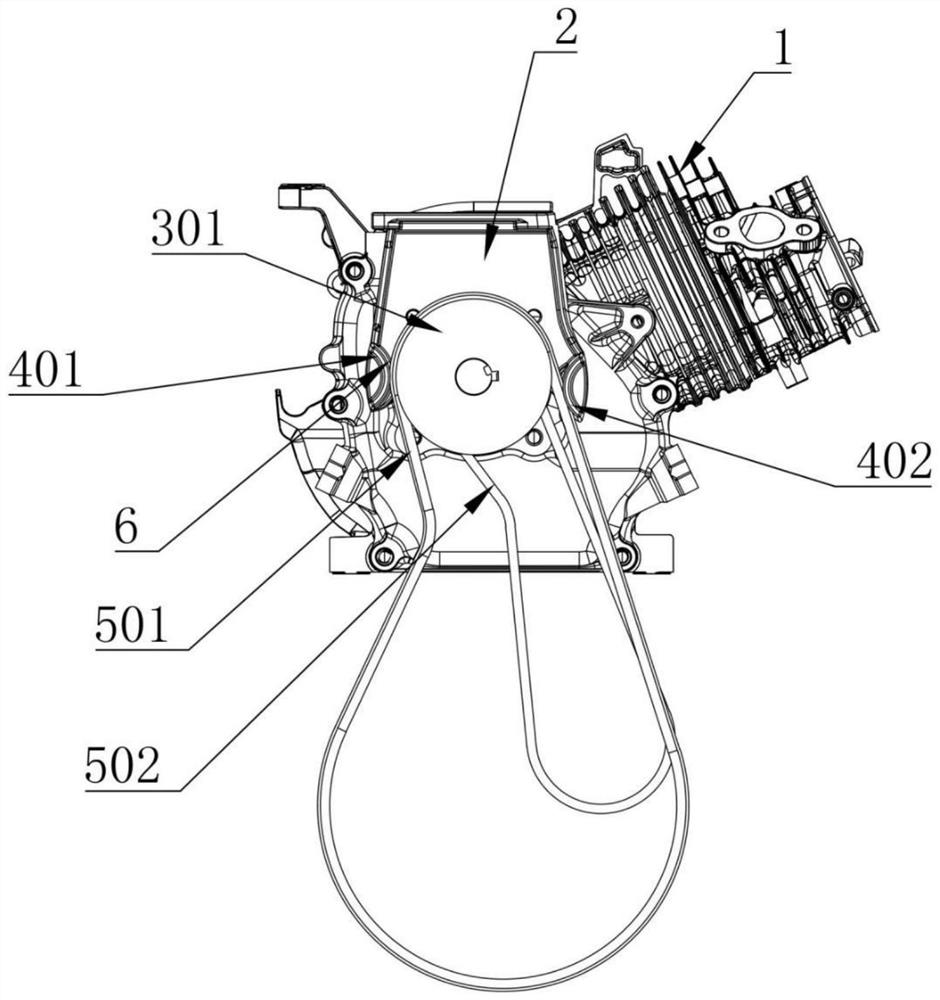

[0021] refer to Figure 1 to Figure 5 , a belt baffle structure of a snowplow, comprising a fixing part 2 arranged on one side of the engine case 1, one side of the engine case 1 is connected with a first pulley 301 through an output shaft 101, and the first pulley 301 is provided with There is a first belt 501 connected to an external driving device, and one side of the fixing member 2 is provided with a stopper 4 for stopping the first belt 501, and the stopper 4 includes: a first stopper 401 and a second stopper Block 402, the first stop block 401 and the second stop block 402 are placed at both ends of one side of the fixture 2, and the inner sides of the first stop b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com