Pipeline through-wall culvert filling construction process

A construction technology and pipeline technology, applied in the direction of pipes, general water supply conservation, pipes/pipe joints/fittings, etc., can solve problems such as difficult operation for construction personnel, leakage, and difficult operation of construction methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

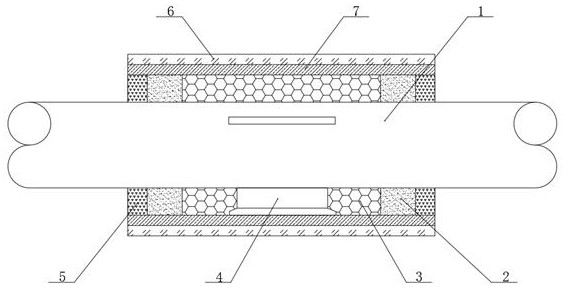

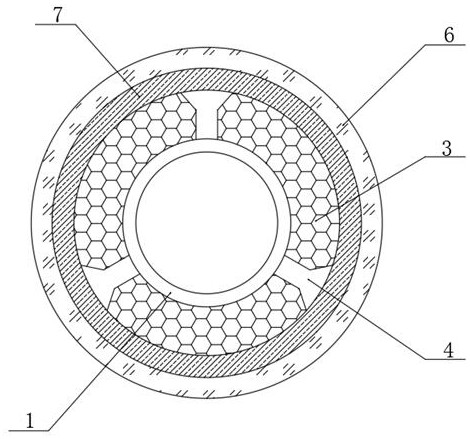

[0022] see Figure 1~2 , in an embodiment of the present invention, a construction process for pipeline through-wall culverting, comprising a pipeline 1 penetrating through the wall, including the following construction steps:

[0023] Step 1: Put a wall-piercing sleeve 7 on the outside of the pipe 1 at a position corresponding to the wall, and weld and fix three supporting steel plates 4 that are respectively against the outer wall of the pipe 1 at equal intervals at the position of the inner middle section of the wall-piercing sleeve 7, It is used to ensure that the pipeline 1 is always at the center of the wall bushing 7;

[0024] Step 2: Prepare the foam filler 3 and fill it into the gap between the wall bushing 7 and the pipe 1 by spraying to form the first waterproof seal, and remove excess scraps at both ends to make the foam filler The overall length of the material 3 is shorter than the length of the wall-piercing sleeve 7, ensuring that there is a reserved space bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com