Electrostatic state capacity shape change detector

A technology of capacity and state, applied in the direction of measuring devices, instruments, etc., can solve the problems of lowering accuracy, lowering detection accuracy, etc., and achieve the effect of reducing production cost, keeping accuracy and resolution unchanged, and being widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

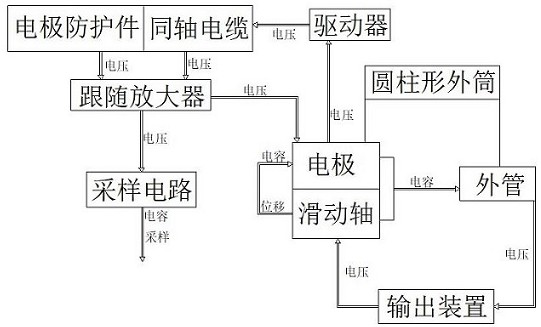

[0017] see figure 1 , the present invention provides a technical solution: a detection of capacitance shape variation in an electrostatic state, the detection of capacitance shape variation in an electric state includes a cylindrical outer cylinder, and the cylindrical outer cylinder is slidably loaded with a metal sliding shaft, and an outer tube is slidably connected to the sliding shaft, and a sampling circuit is arranged outside the outer tube.

[0018] Preferably, an output device, an electrode and a protective pole are arranged outside the sliding shaft, and the electrode is surrounded by an electrode guard.

[0019] Preferably, a coaxial cable is arranged outside the cylindrical outer cylinder, and a follower amplifier and a driver are arranged outside the output device.

[0020] A capacitance shape variation detection in an electrostatic state, the capacitance shape variation detection in an electrostatic state includes the following steps:

[0021] S1: The outer tub...

Embodiment 2

[0027] A capacity shape variation detection in an electrostatic state, the capacitance shape variation detection in an electric state includes a cylindrical outer cylinder, the cylindrical outer cylinder is slidably loaded with a metal sliding shaft, and the sliding shaft is slidably connected There is an outer tube, and a sampling circuit is arranged outside the outer tube, an output device, an electrode and a protective pole are arranged outside the sliding shaft, an electrode guard is surrounded on the outside of the electrode, and a coaxial cable is arranged outside the cylindrical outer cylinder , and the output device is provided with a follower amplifier and a driver.

[0028] A capacitance shape variation detection in an electrostatic state, the capacitance shape variation detection in an electrostatic state includes the following steps:

[0029] S1: The outer tube is near the outer circumference of the sliding shaft. The capacitance-voltage conversion circuit converts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com