Prober

A probe station and probe technology, applied in the field of probe station, can solve the problem of not being provided, and achieve the effects of eliminating stray capacitance, reducing the influence of external noise, and suppressing current leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, the present invention will be described using the drawings, but of course the probe station of the present invention is not limited to the illustrated probe station.

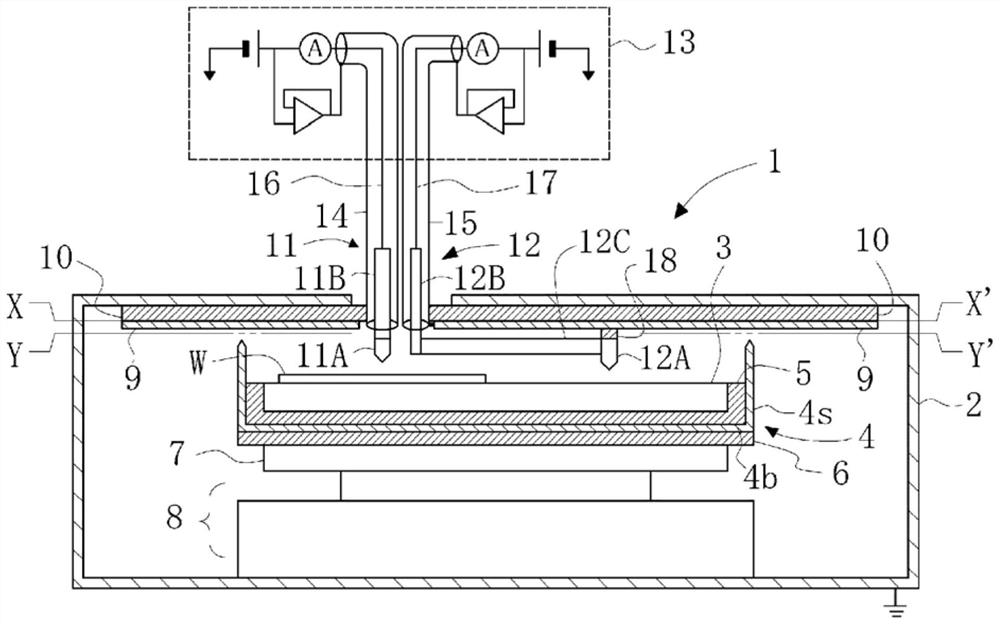

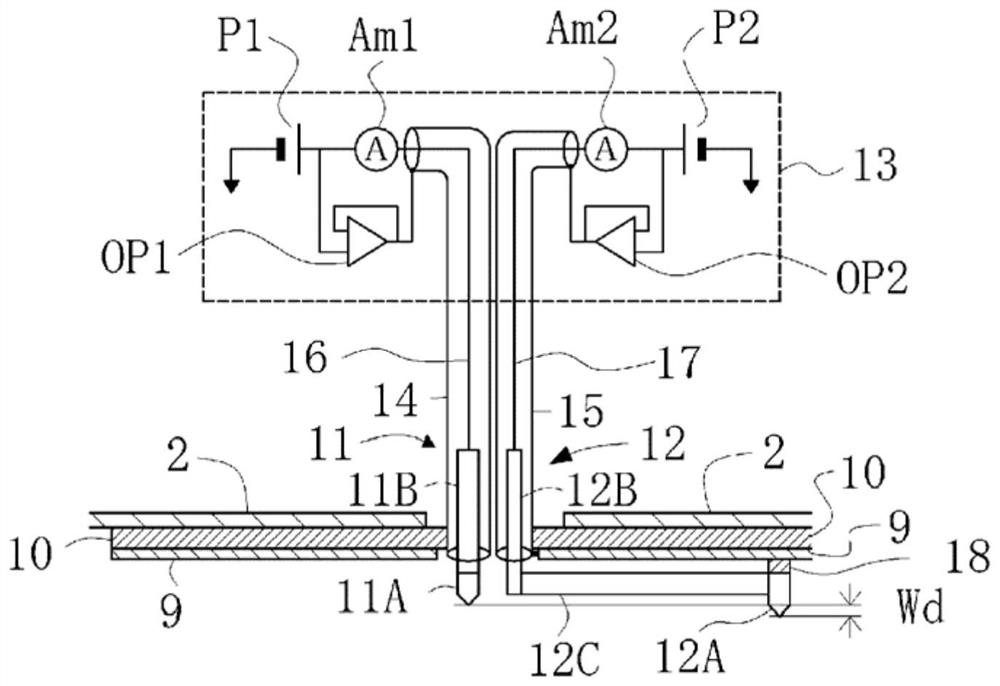

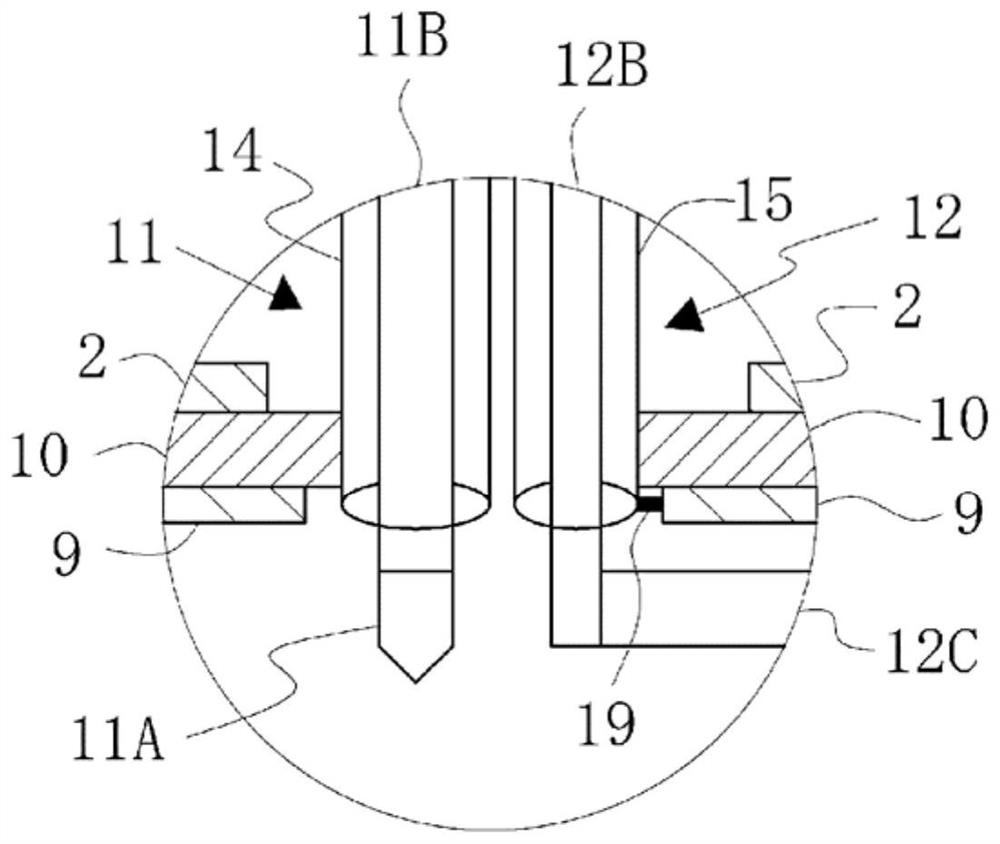

[0054] figure 1 It is a partial front sectional view showing an example of the probe station of the present invention. exist figure 1 Among them, 1 is the probe station of the present invention, 2 is the frame body, 3 is the chuck stage, and 4 is the chuck cover conductor. The chuck cover conductor 4 has a bottom conductor 4b and a side conductor 4s, and its upper surface is open. 5 is an insulator disposed between the chuck stage 3 and the chuck cover conductor 4 . As shown in the figure, the height of the side conductor 4s of the chuck cover conductor 4 is set so that the top end thereof is higher than the upper surface of the chuck stage 3, and the chuck stage 3 is embedded with the insulator 5 into the The space surrounded by the bottom conductor 4b and the side conductor 4s of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com