Direct current contactor insulation performance detection device

A DC contactor and insulation performance technology, which is applied in the direction of measuring devices, measuring device shells, and grounding resistance measurements, can solve the problems of high misjudgment rate, poor consistency, and low efficiency of manual insulation resistance testing, so as to improve utilization rate, The effect of saving working space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

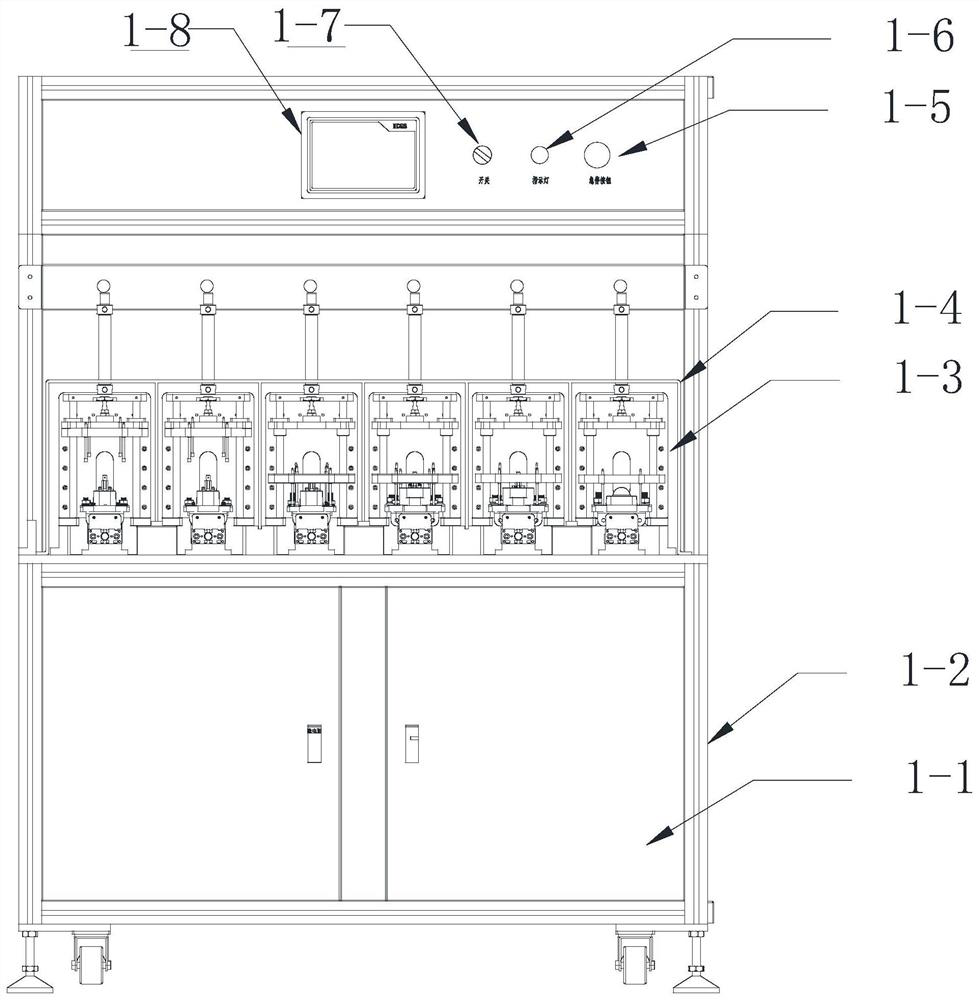

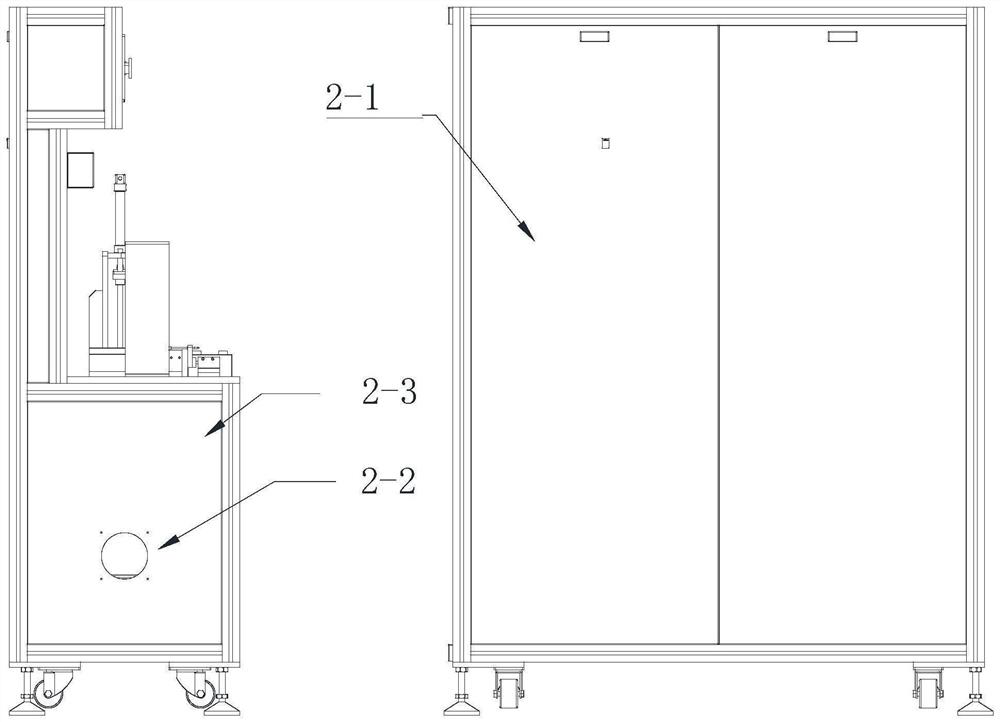

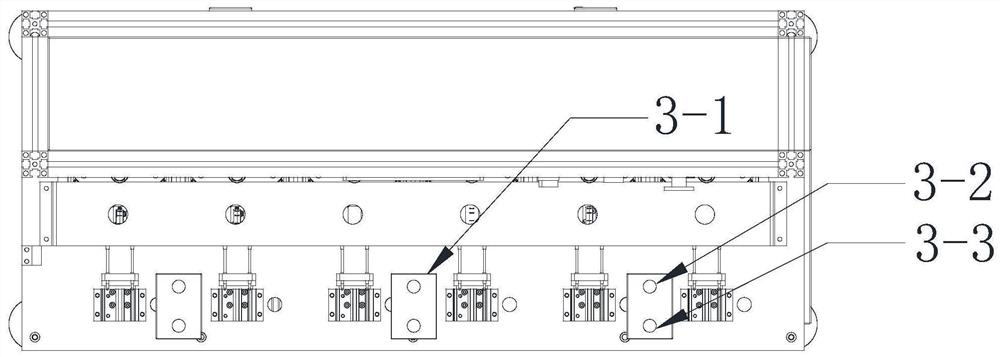

[0044] like Figure 1 to Figure 11As shown, the present invention discloses a DC contactor insulation performance detection device, including a cabinet, a compatible detection mechanism for product positioning and connection testing, a control switch, and an electric control component. The compatible detection mechanism is installed on the cabinet. The compatible detection mechanism includes a slide assembly, a press-down cylinder, a probe assembly and a special-shaped pad for fixing the DC contactor to be tested. The press-down cylinder is connected to the slide assembly, and a probe assembly is installed on the slide assembly. The probe assembly Driven by pressing down the cylinder, it is in contact with the DC contactor to be tested to be installed on the base. The detection station device is installed at the bottom of the cabinet, and the detection station device includes an insulation resistance meter composed of several insulation resistance The resistance side instrumen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com