Powder patting and falling device of full-automatic pressure-free magnetic powder forming machine

A molding device and fully automatic technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve problems such as density differences and achieve highly uniform results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

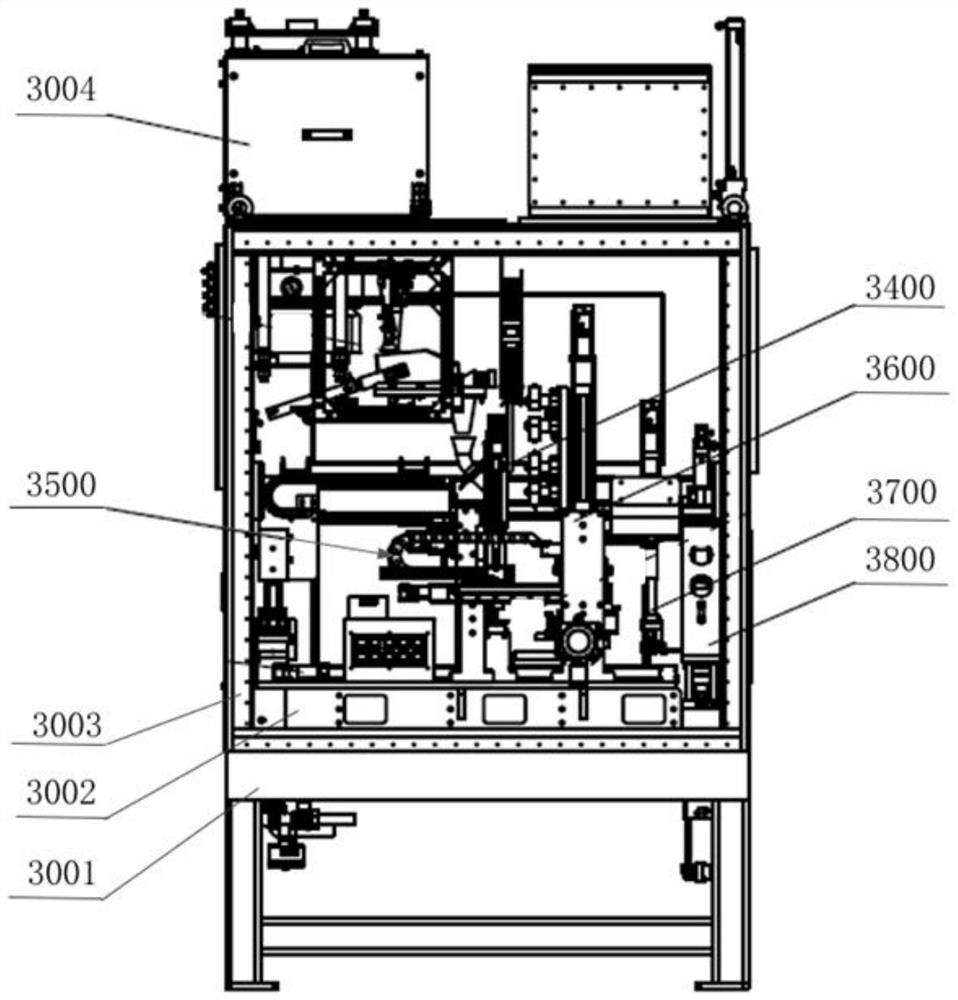

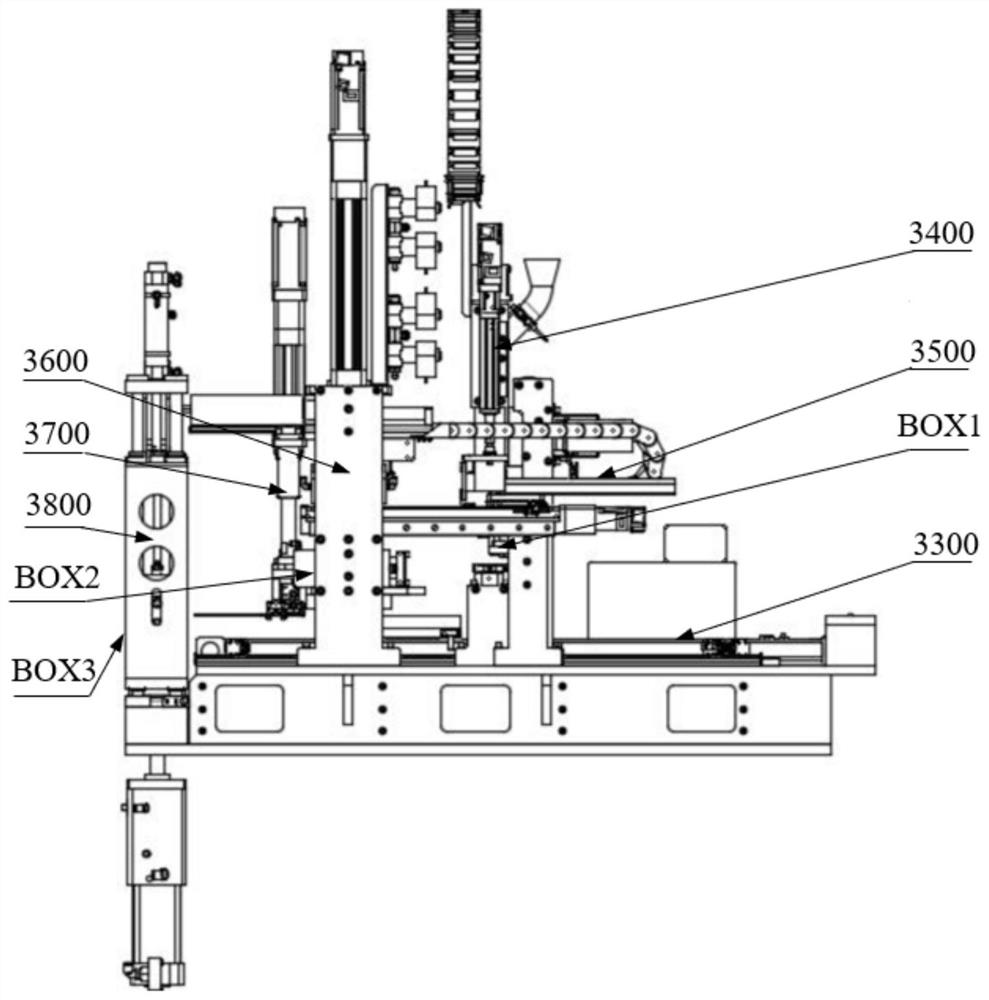

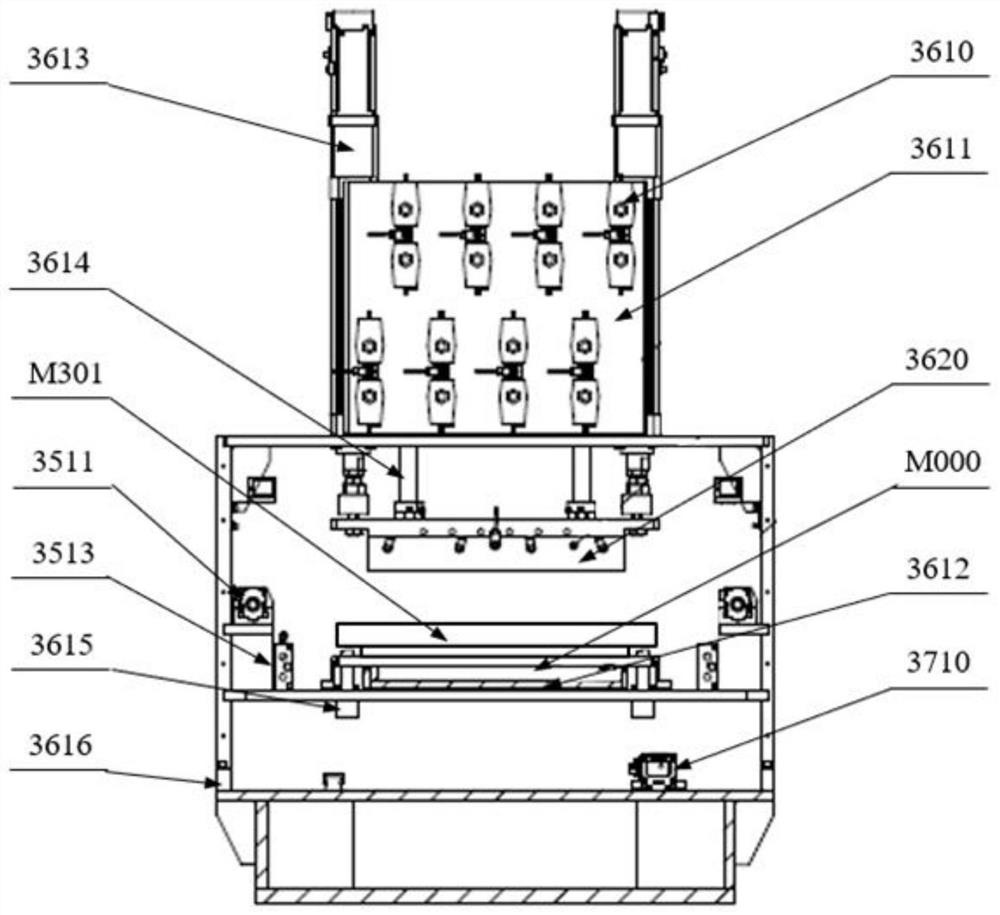

[0024] see Figure 1 to Figure 5, Specific embodiment 1, this embodiment 1 provides a kind of fully automatic non-pressure magnetic powder molding machine powder-beating and dropping device, characterized in that: the powder-beating and dropping device includes an air-beating device 3600 and a powder-dropping forming device 3800, The air-patting device 3600 includes a material box screen M301b, a powder distribution mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com