Wheel translation transmission mechanism

A transmission mechanism and wheel technology, applied in vehicle components, control devices, transportation and packaging, etc., can solve problems such as the inability to solve the problems of energy saving and environmental protection of automobiles, the inability to balance and increase the force, and the inability to solve the safety problems of automobile braking. Dynamic performance and adaptive matching performance, improving acceleration performance, avoiding the effect of sudden traffic hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

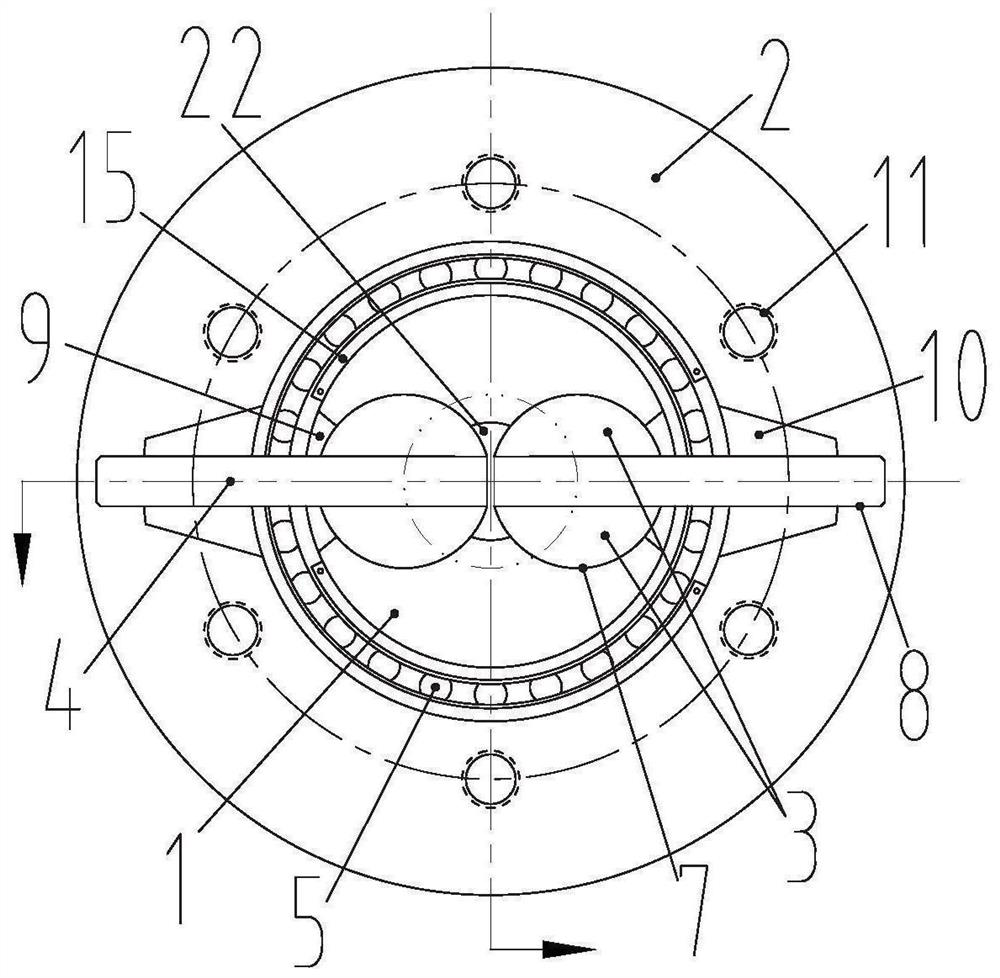

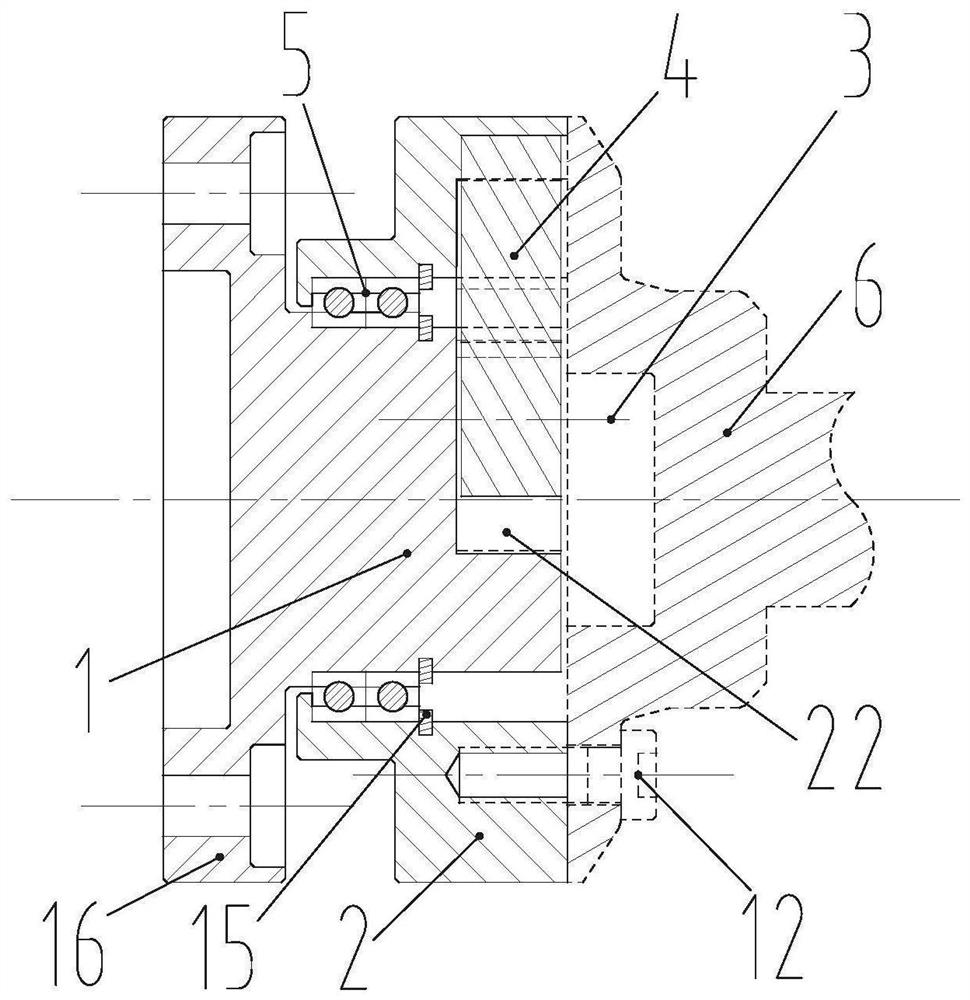

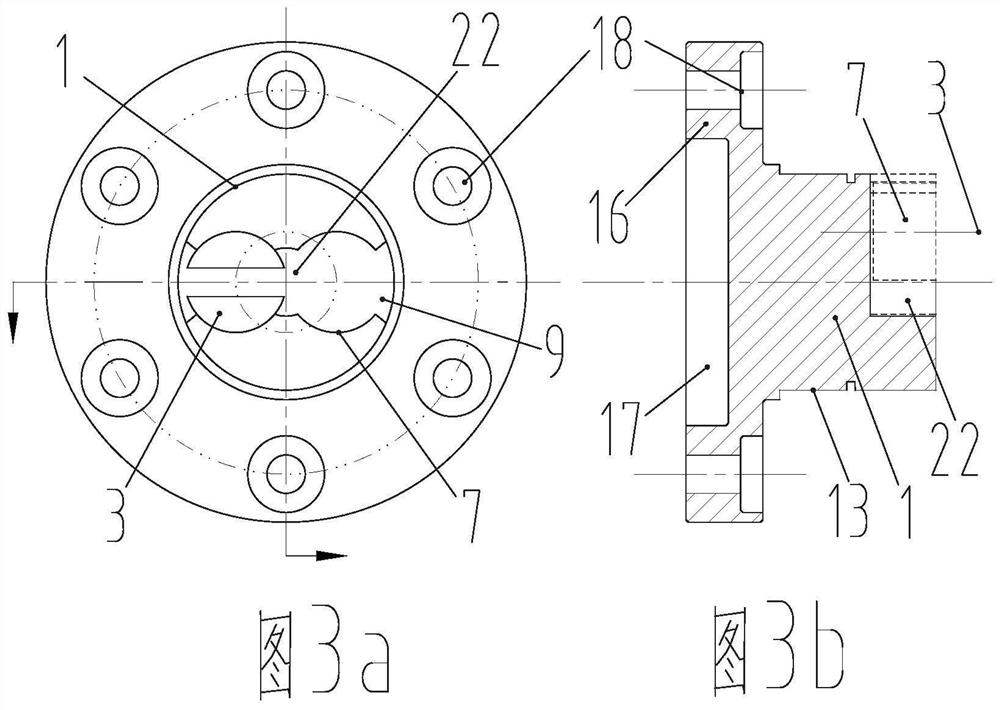

[0035] Compared with embodiment 1, embodiment 2 is only different in the number of combined star wheels and main shaft circular grooves, elastic cuboids and rectangular grooves of slave shafts. The former uses three combined star wheels and three elastic cuboids, and the latter uses two A combined star wheel and two elastic cuboids, considering the structural symmetry, therefore, only the axial transverse and axial longitudinal cross-sectional schematic diagrams of the overall assembly structure of embodiment 2 are given here, and its structural composition description can also refer to the embodiment 1 to understand the structural composition schematic diagram, the components of the two embodiments are described with the same lead wire labels, and will not be described again.

[0036] The production process design of the relevant parts is considered. The main shaft, slave shaft, combined star wheel and slave shaft flange can all be made of 45 or 40Cr steel and processed by con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com