Overhead rail AI artificial intelligence inspection robot and positioning fire extinguishing method of robot

A technology of intelligent robots and inspection robots, which is applied in fire rescue and other fields, can solve problems such as the inability to accurately and zero-falsely report early flame/small flame positioning, the inability of robots to automatically respond to emergencies, and the inability to achieve ultra-high temperature early warning and self-positioning functions. Achieve the effect of reducing losses, eliminating uncontrollable and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

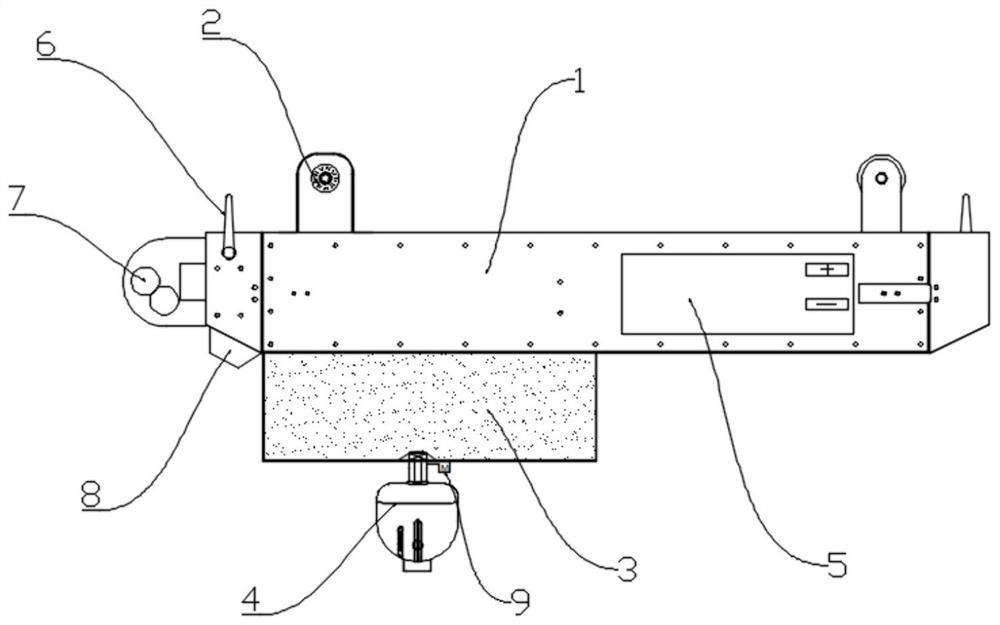

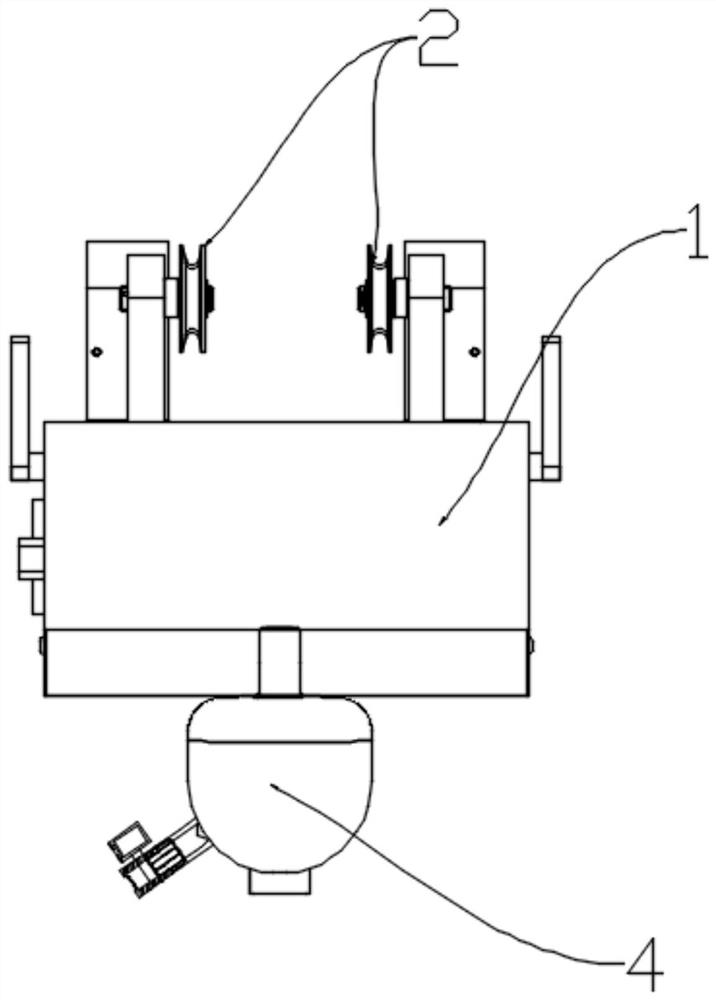

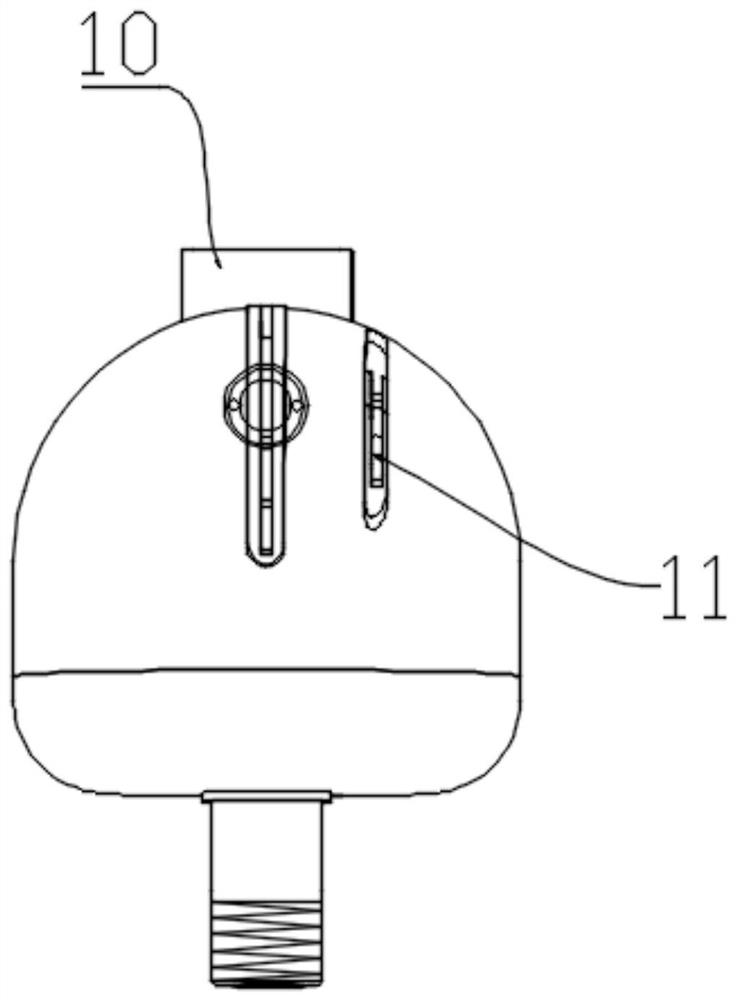

[0034] refer to Figure 1 to Figure 6A hanging rail AI artificial intelligence inspection robot and a positioning and fire extinguishing method for the robot are shown, including an intelligent robot main body 1 and a server. The intelligent robot main body 1 and the server use a 485 communication protocol for network signal transmission and connection, and the intelligent robot main body 1 The upper end of the intelligent robot is provided with a drive wheel 2, and a battery 5 is provided inside it. The lower end of the intelligent robot main body 1 is provided with an emergency spray medium container 3. One end of the intelligent robot main body 1 is provided with an AI camera, an infrared thermal imaging lens and a red The infrared thermal scanning pan / tilt 7 composed of ultraviolet flame spectrum sensors, the infrared thermal imaging lens is used to thermally scan the scene and form a heat map, and the AI camera is used to take visible light photos of the scene and superi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com