A kind of LED display film coater and film coating method thereof

A technology of LED display and display screen, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of increased display dust, prone to static electricity, affecting appearance, etc., and achieves increased integrity. and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

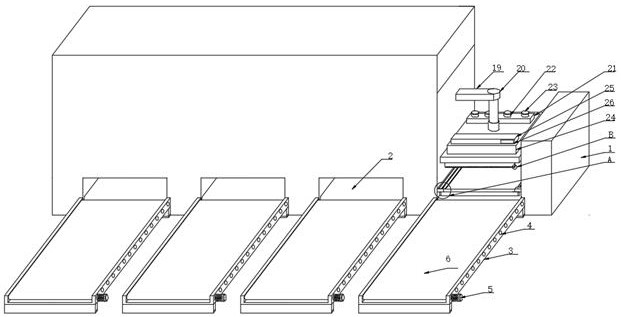

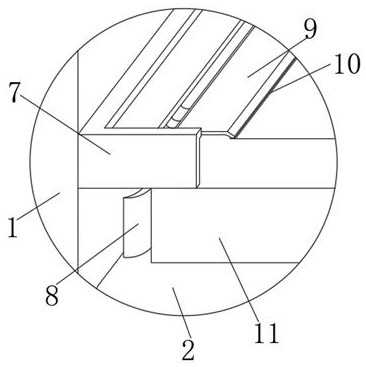

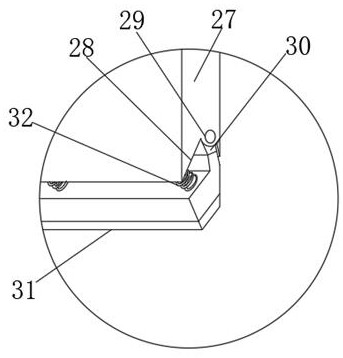

[0035] like Figure 1-10 As shown, the invention provides a kind of LED display film coater, comprising:

[0036] The equipment casing 1 is provided with a plurality of coating channels for LED display screens on the equipment casing 1, and the transmission type coating platform 2 is arranged in the coating channel. A transmission shaft 4 is arranged at a distance, and a transmission belt 6 is connected to the transmission shaft 4, and a servo motor 5 is fixedly connected to the right side of the transmission shaft 4 on the rear side, and the output end of the servo motor 5 is fixedly connected to the right side of the transmission frame 3, The left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com