Mems ultrasonic transducer with high emission performance

An ultrasonic transducer, ultrasonic technology, applied in the direction of fluid using vibration, etc., can solve the problems of unable to meet the bandwidth requirements, difficult to achieve bandwidth, insufficient emission sound pressure, etc., to optimize the size of the deep groove and increase the emission sensitivity , Improve the effect of output sound pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

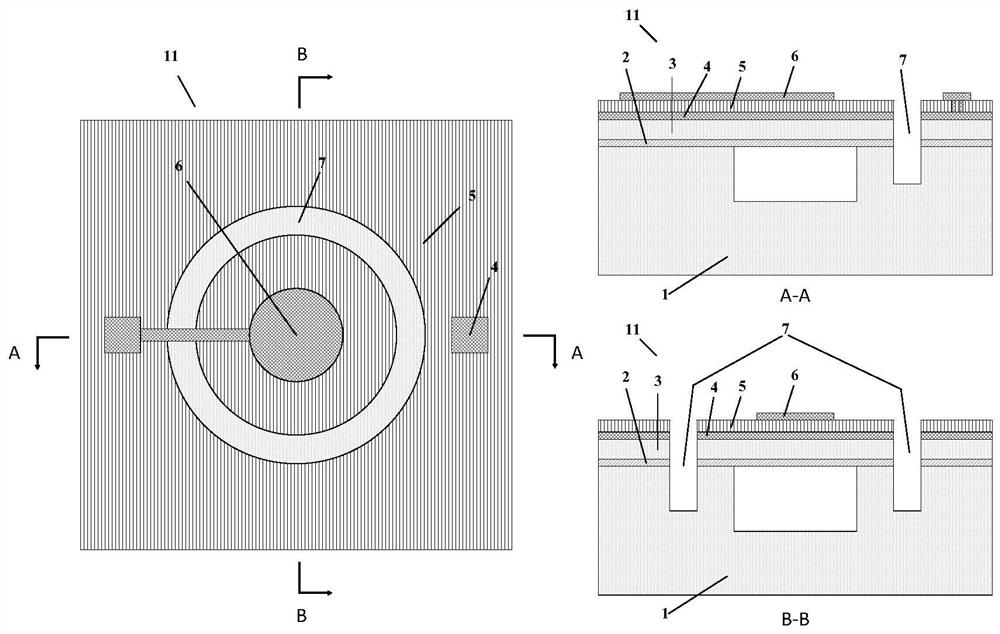

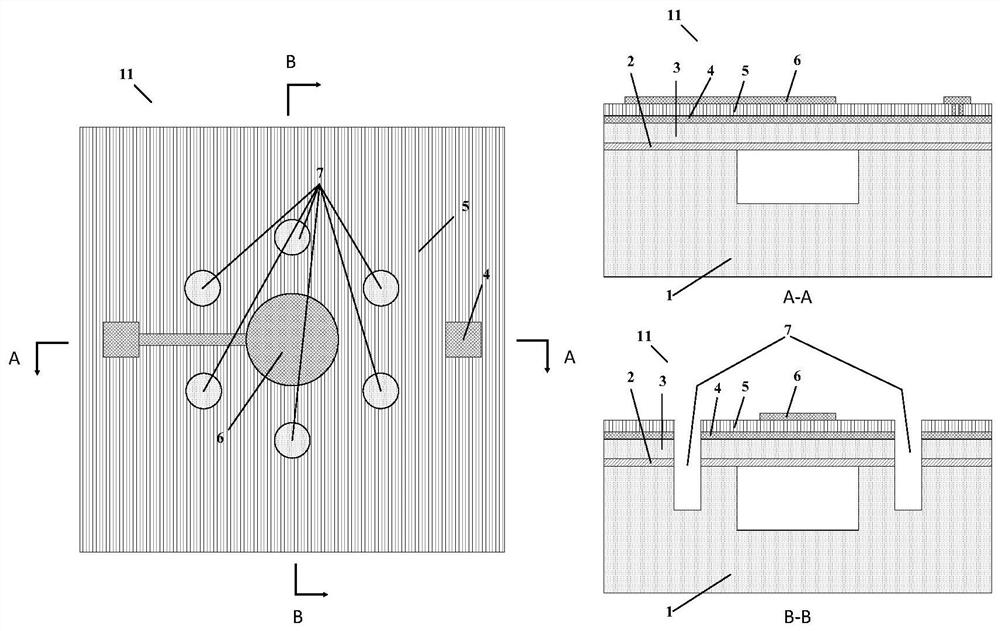

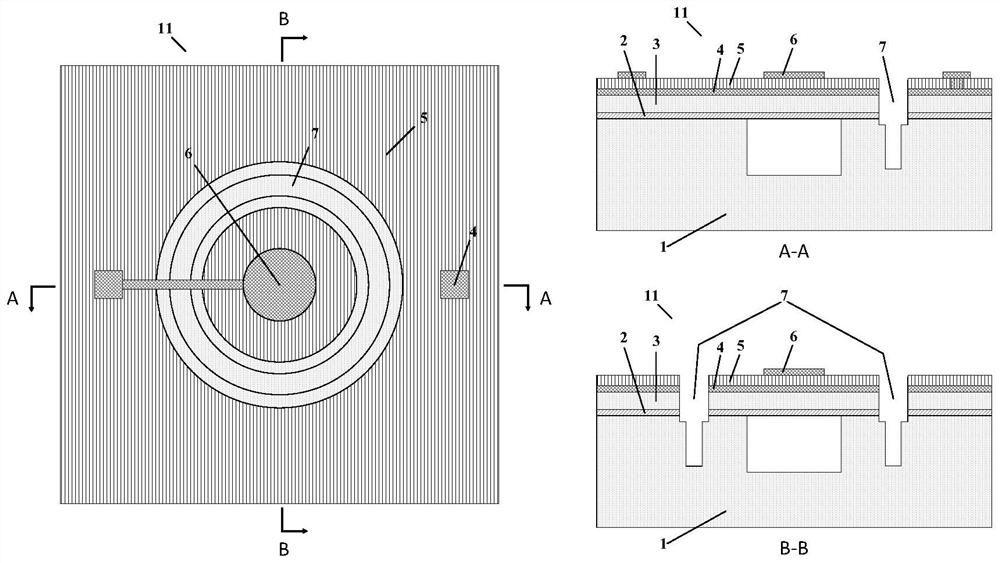

[0026] The MEMS ultrasonic transducer includes sequentially stacked substrates 1, SiO 2 layer 2, passive layer 3, lower electrode 4, piezoelectric layer 5 and upper electrode 6. figure 1 An ultrasonic transducer 11 is shown having a penetrating piezoelectric layer 5, a bottom electrode 4, a passive layer 3 and SiO 2 Deep groove 7 of layer 2 , deep groove 7 extends over a length in substrate 1 . When the ultrasonic wave emitted by the ultrasonic transducer 11 reaches the deep groove 7, it will cause the medium in the deep groove 7 to vibrate, and radiate sound waves outward. The sound field on the surface of 11 interacts, and the distribution of the additional sound field can be adjusted by adjusting the size of the deep groove 7, such as length, width, and the distance from the central axis of the ultrasonic transducer 11, so as to realize the loud pressure output of the ultrasonic transducer 11 Or widen the bandwidth. Specifically, the sound pressure of the ultrasonic tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com