mems piezoelectric speaker

A piezoelectric speaker, speaker technology, applied in electrostatic transducer speakers, microphones, piezoelectric/electrostrictive transducers, etc., can solve the problems of small size and speaker performance constraints, achieve large effective length, improve vibration Amplitude, the effect of increasing the output sound pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

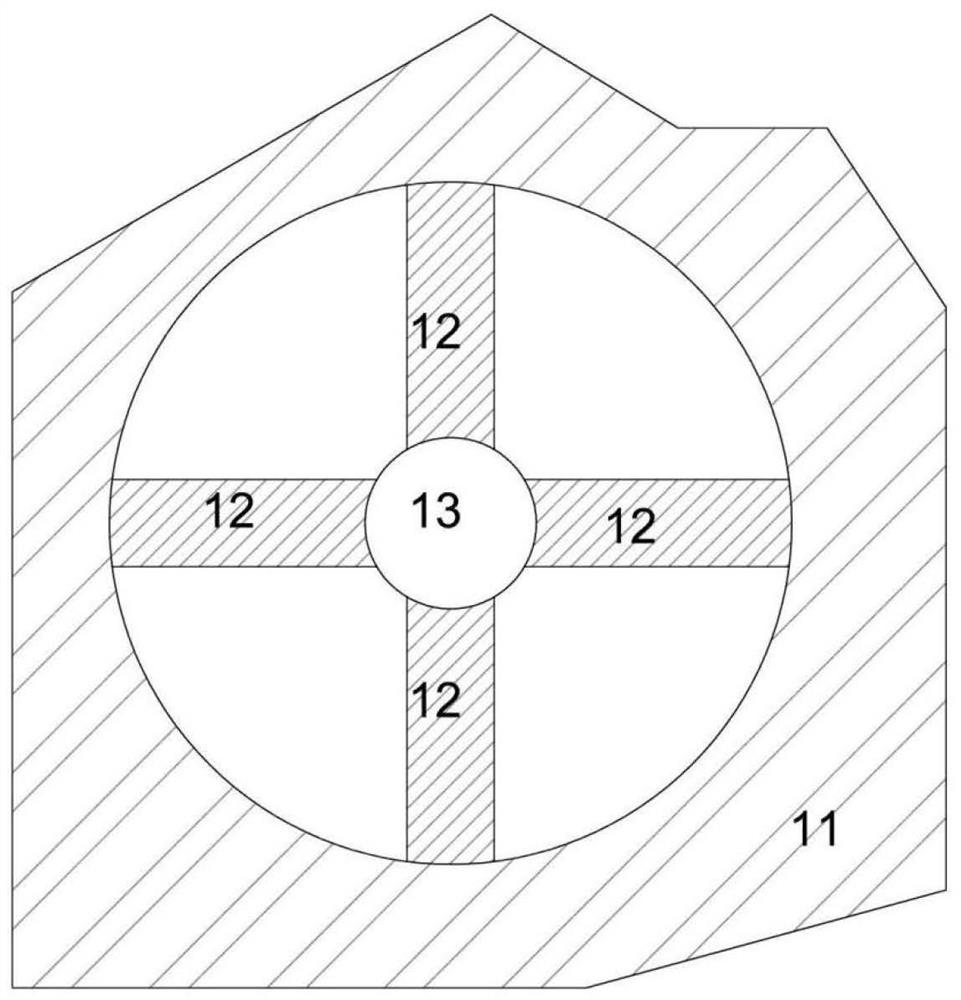

[0064] figure 1 In the MEMS speaker in the prior art shown, its load plate 13 is located on the extension line of the strip branch of the actuator 12. According to this layout, in the case of a certain overall area of the speaker, if the length of the actuator branch is to be guaranteed , the area of the load plate is affected. If the area of the load plate is to be increased, the length of the actuator branch needs to be shortened. Therefore, this layout cannot take into account the area of the load plate and the length of the actuator branch, which affects the output sound pressure of the speaker. On the other hand, the simple rectangular shape of the actuator leads to its low equivalent bending flexibility, which is reflected in the small maximum displacement of the actuator (that is, the limited displacement of the load plate), which ultimately affects the maximum outputtable sound pressure of the speaker.

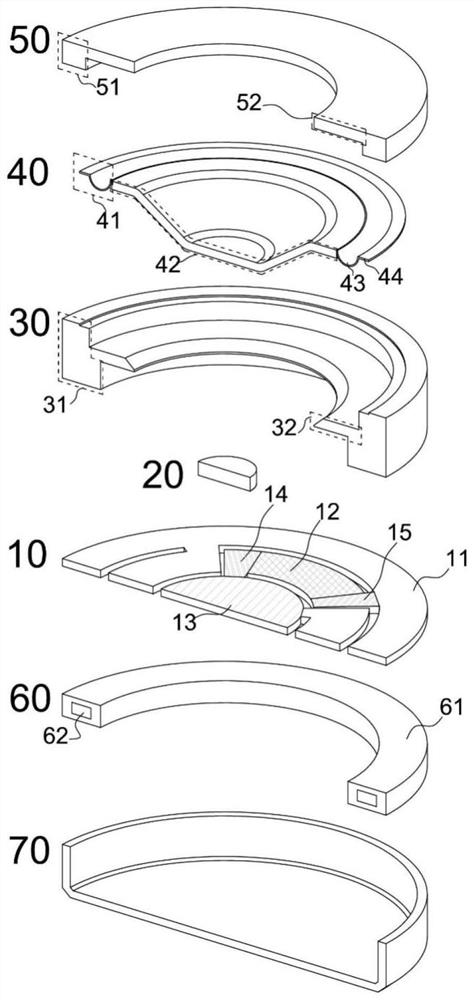

[0065] In the embodiment of the present invention, relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com