Double-wheel high-precision grinding machine applied to roller manufacturing

A grinding machine, high-precision technology, applied in the direction of manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, metal processing equipment, etc., can solve problems such as long time, small contact surface, and surface accuracy that cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

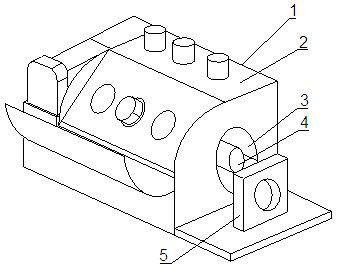

[0056] Such as Figure 1-11 As shown, the present invention provides a double-wheel high-precision grinding machine applied to roller manufacturing and processing, including a grinding machine body 1, a grinding machine frame body 2 and a grinding seat 5, and the grinding machine body 1 includes a grinding machine frame body 2. A grinder mechanism 3 is fixedly connected to the inside of the grinder frame body 2 , a fixed roller 4 is arranged inside the grinder mechanism 3 , and a grinding seat 5 is fixedly connected to the outer surface of the grinder frame body 2 .

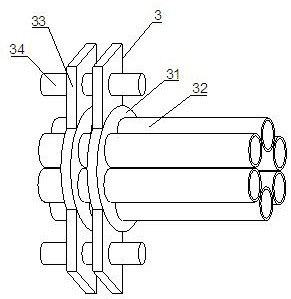

[0057] The grinder mechanism 3 includes a fixed circular plate 31 , and a friction cylinder 32 is fixedly connected to the inside of the fixed circular plate 31 , and the friction cylinder 32 includes an outer retainer 2 321 .

[0058] The grinding base 5 includes a pressure-resistant fixture 57 , and the pressure-resistant fixture 57 includes an outer shell 571 .

[0059] In this embodiment, the fixed roller 4 ...

Embodiment 2

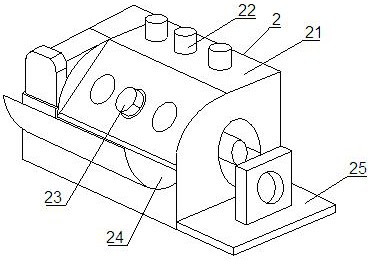

[0063] Such as Figure 1-11 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the grinding seat 5 includes a second bottom plate 51, the outer surface of the second bottom plate 51 is fixedly connected with a slide rail 52, and the outer surface of the second bottom plate 51 An upper slide plate 53 is overlapped on the top, the outer surface of the slide rail 52 is overlapped on the lower surface of the upper slide plate 53, the outer surface of the upper slide plate 53 is fixedly connected with a fixer 54, and the outer surface of the upper slide plate 53 is overlapped with an L-shaped Rotating plate 55, the inside of L-shaped rotating plate 55 is provided with rotating groove 56, and the inner surface of rotating groove 56 is lapped on the outer surface of fixture 54, and the outer surface of L-shaped rotating plate 55 is provided with anti-pressure fixer 57.

[0064] In this embodiment, the cylindrical material is fixe...

Embodiment 3

[0066] Such as Figure 1-11 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer surface of the fixed circular plate 31 is fixedly connected with an external connection plate 33, and the inside of the external connection plate 33 is fixedly connected with a connecting column 2 34, The fixed circular plate 31 includes an outer retainer 311, the inner surface of the outer retainer 311 is fixedly connected with an inner filling plate 312, and the inside of the inner filling plate 312 is fixedly connected with a rotator 313, and the outer surface of the rotator 313 is fixedly connected to the on the outer surface of the friction cylinder 32 .

[0067] In this embodiment, the six friction cylinders 32 fixed on the fixed circular plate 31 form a circle, cooperate with the gap generated in the middle of the friction cylinders 32, and use the rotation of the friction cylinders 32 to grind the surface of the roller in all di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com