Preparation process of graphite column for diamond synthesis

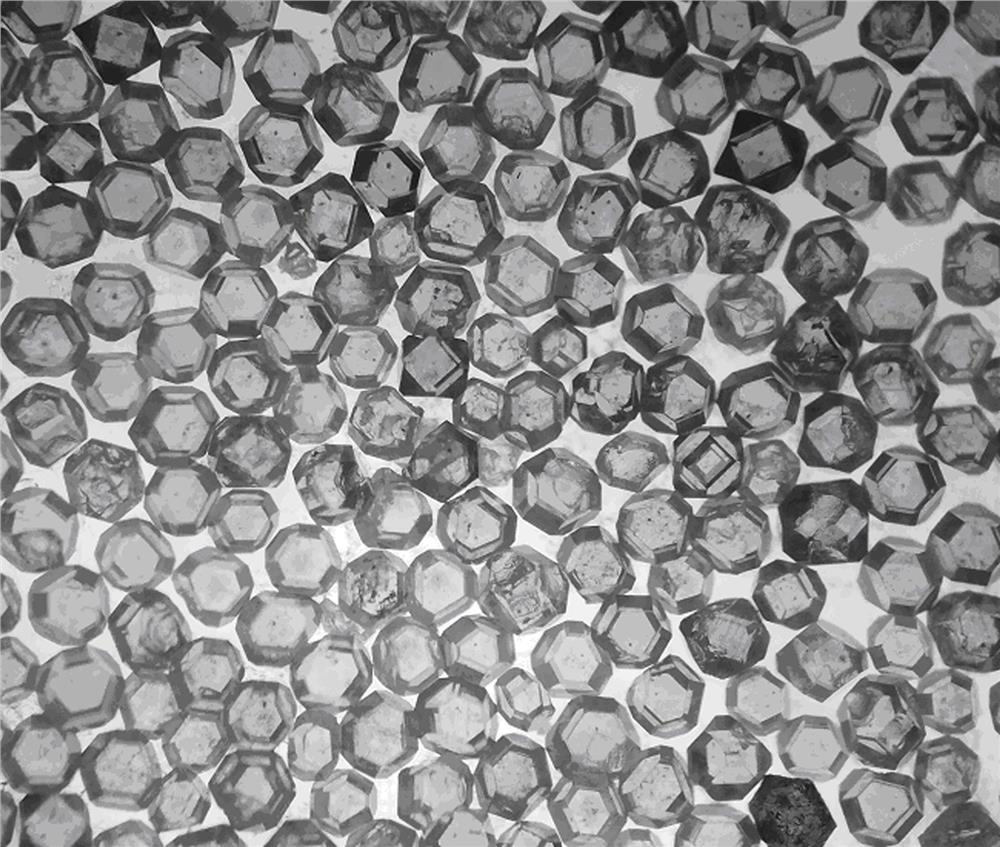

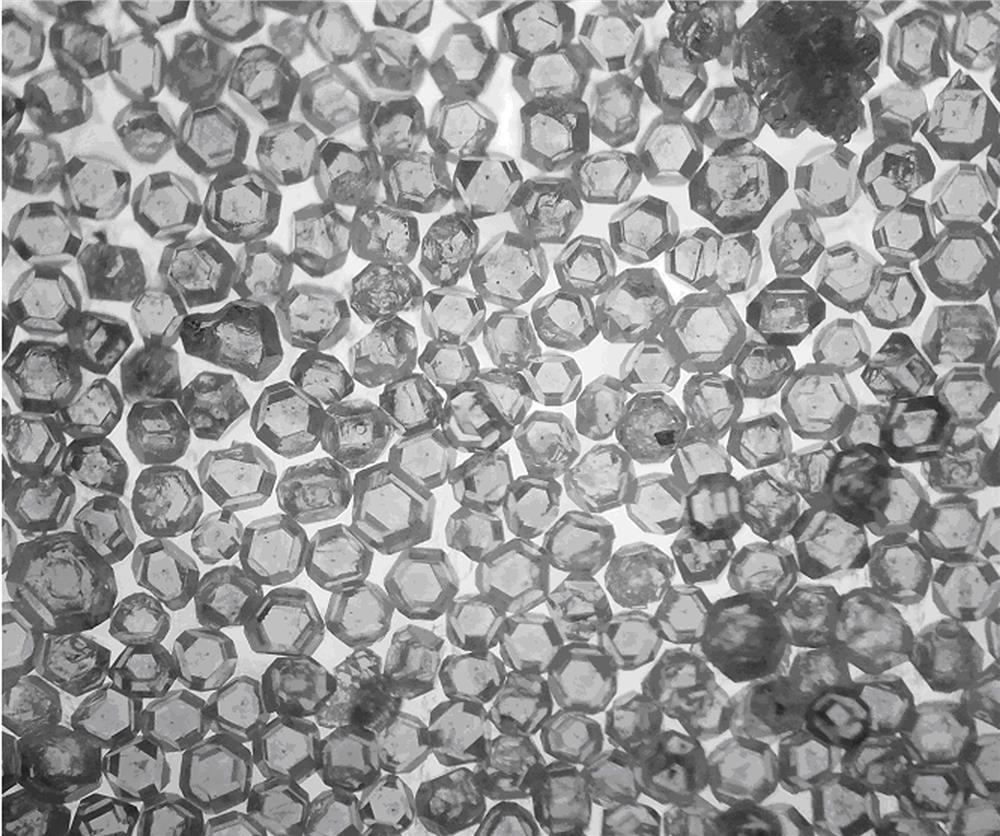

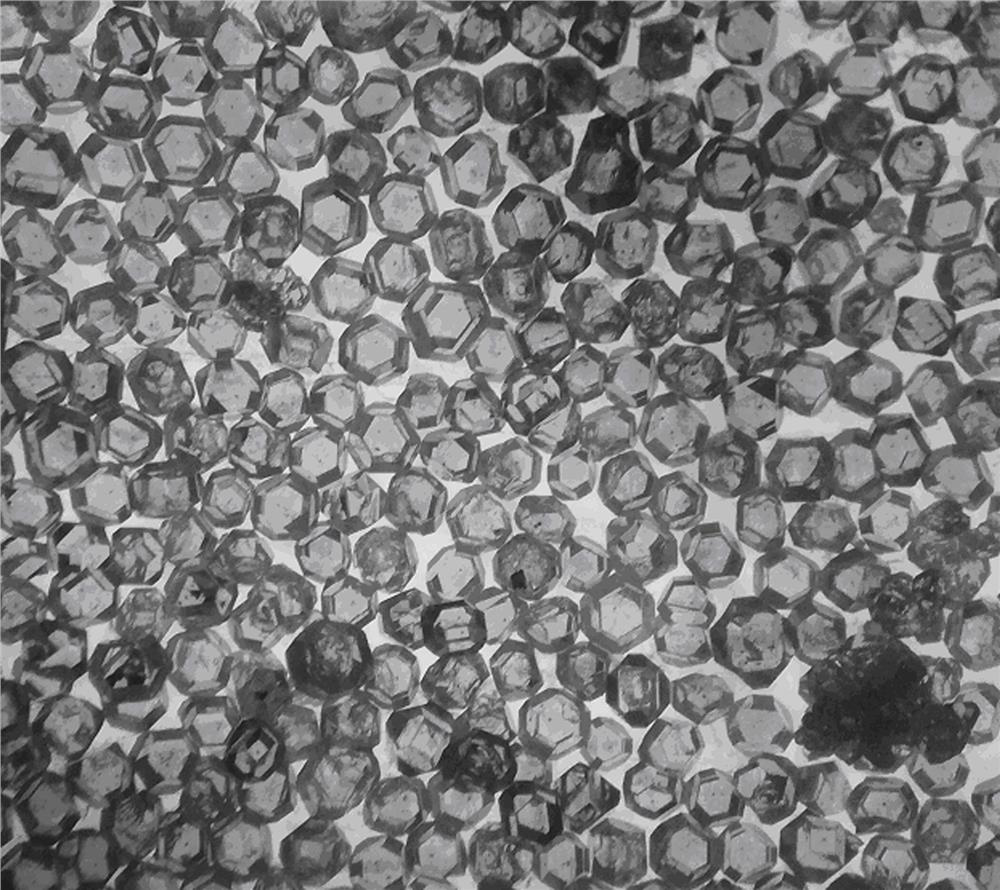

A preparation process, graphite column technology, applied in the application of ultra-high pressure process, manufacturing tools, material molding presses, etc., can solve the problem that the density of graphite columns will not increase, and achieve single crystal growth with good quality and concentrated particle size The effect of high density and high crystal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Metal powder and graphite powder press the graphite column according to the formula of 5:5, and weigh -200 mesh FeNi 3050kg of metal powder, 49kg of high-purity scaly graphite powder with a fineness of 300 mesh or more, and 1kg of nucleating agent for standby. First, add 50kg of metal powder and 1kg of nucleating agent into a 200L three-dimensional mixer, adjust the speed of the mixer to 70r / min, mix for 1.5 hours, add 0.6kg of dispersant solution, mix for 3 hours and then add Graphite powder and the dispersant of 1kg, then continue to mix 3 hours in the mixer. After the mixing is completed, transfer to the double-roll extruder for granulation as soon as possible. The finishing time cannot exceed 1 hour. The speed of the double-roll extruder is set at 1500r / min, and the material is repeatedly granulated twice. Afterwards, the granulated material was pressed and formed on a 150-ton four-column press, the diameter of the mold cavity was 70.8mm, and the weight of the grap...

Embodiment 2

[0036] The difference between this embodiment and Implementation 1 is the difference in the mixing method. In order to compare the technical effects of the conventional mixing method and the graded mixing method of the present invention, this embodiment is designed as a conventional graphite column mixing process. The specific process The process is:

[0037] Press the metal powder and graphite powder into the graphite column according to the formula of 5:5, and first weigh the FeNi finer than 200 mesh 30 50kg of metal powder, 49kg of fine high-purity scaly graphite powder with a size of 300 mesh, and 1kg of nucleating agent for spare use. Add the metal powder, graphite powder, nucleating agent and 1.6kg of dispersant weighed above into the three-dimensional mixer at the same time , the mixing time is set to 8 hours, the speed of the mixer is set to 70r / min, after the mixing is completed, the material is loaded into the silo of the granulator, the speed of the granulator is se...

Embodiment 3

[0039] The difference between this embodiment and Implementation 1 lies in the difference in the pressing method. In order to compare the technical effects of the conventional pressing method and the reheating and repressing method of the present invention, this embodiment is designed as a conventional graphite column pressing process, and the specific process is as follows: :

[0040] Press the metal powder and graphite powder into the graphite column according to the formula of 5:5, first weigh 50kg of FeNi30 metal powder with a size of 200 mesh or finer, 49kg of high-purity scaly graphite powder with a finer size of 300 mesh or smaller, and 1kg of nucleating agent for later use. First, add 50kg of metal powder and 1kg of nucleating agent into a 200L three-dimensional mixer, adjust the speed of the mixer to 70r / min, mix for 1.5 hours, add 0.6kg of dispersant solution, mix for 3 hours and then add Graphite powder and the dispersant of 1kg, then continue to mix 3 hours in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Sub diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com