Distributed drive system for leaf spring suspension

A drive system and leaf spring suspension technology, applied in the direction of power unit, electric power unit, control device, etc., can solve the problems of poor dynamic control performance of the whole vehicle, and the safety of the whole vehicle needs to be improved, so as to improve the power of the whole vehicle The effects of learning control performance, improving vehicle safety, and fast response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

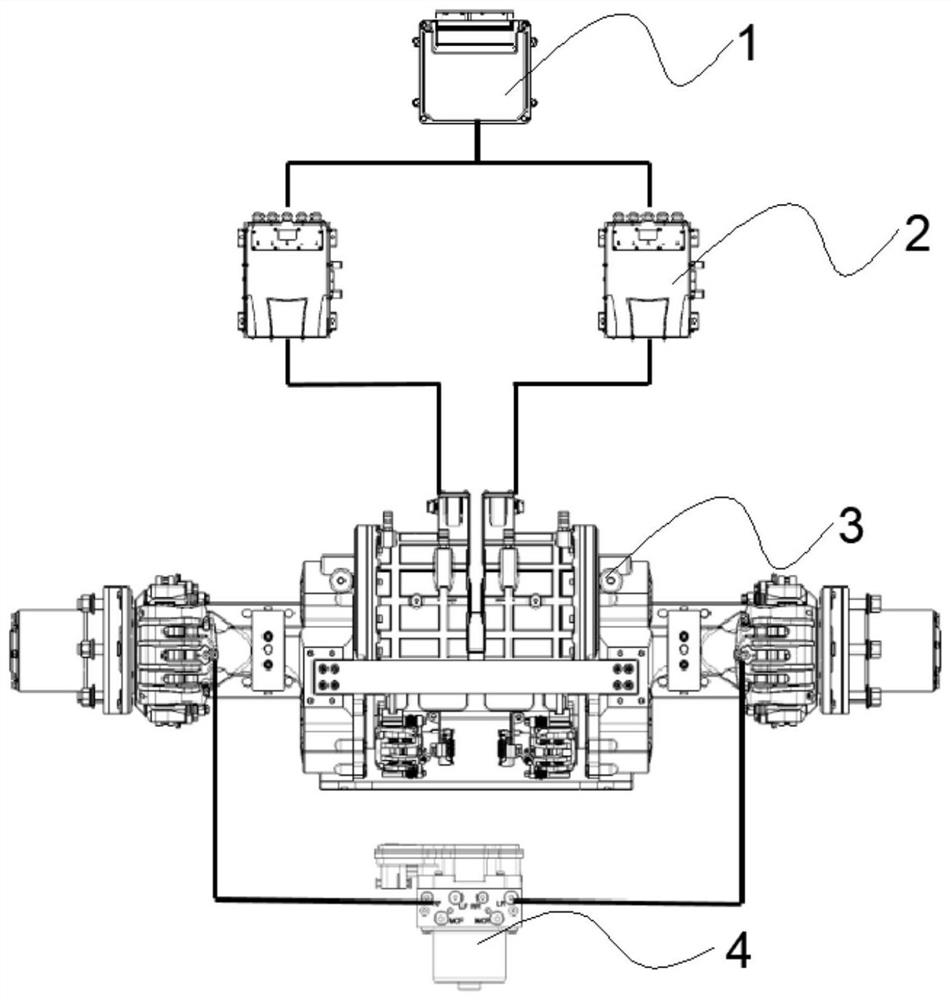

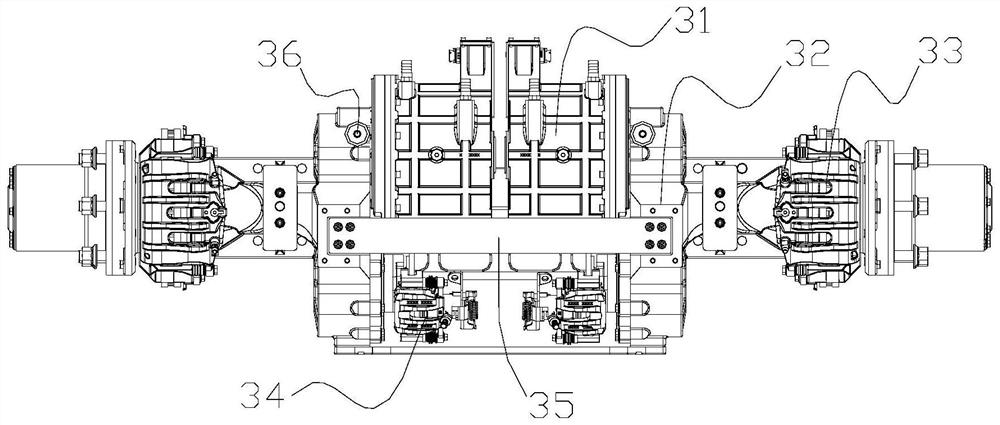

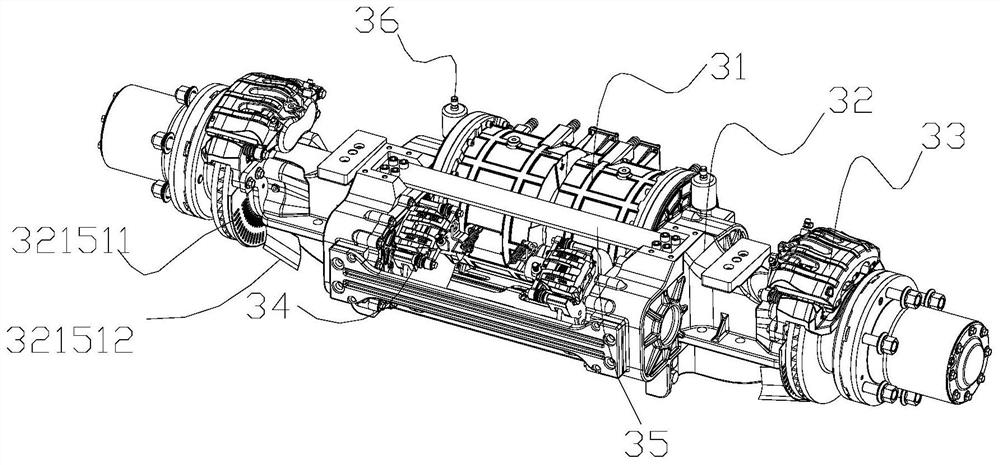

[0055] Such as figure 1As shown, the embodiment of the present invention provides a distributed drive system suitable for leaf spring suspension, including DCU1, motor controller 2, distributed drive axle 3 and HCU valve 4.

[0056] The DCU1 is used to control the two motor controllers 2 and the HCU valve 4 to maintain the stable running of the vehicle body.

[0057] In terms of expansion, DCU mainly plays the role of electronic differential control, drive anti-skid control and body stability control. The main principle is that the DCU recognizes the driver's intention according to the accelerator pedal signal, brake pedal signal, gear position signal, etc., judges the vehicle state through the vehicle speed, wheel speed, vehicle yaw acceleration and other signals, and then combines the driver's intention with the vehicle The state separately controls the two motors of the distributed drive axle and the HCU adjusts the braking force of the brake to make the vehicle run safely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com