Oil sand multi-stage separation device

A multi-stage separation and oil sand technology, which is only applied in the direction of multi-stage serial refining process treatment, petroleum industry, and hydrocarbon oil treatment, to achieve low oil content and reduce floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

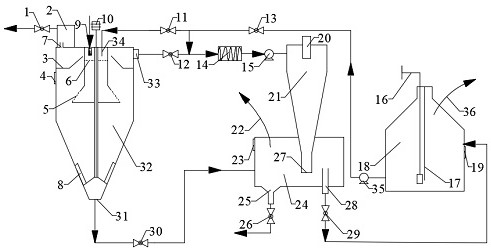

[0017] figure 1 Shown is a schematic structural diagram of a multi-stage oil-sand separation device, taking sandy heavy oil for oil-sand separation as an example, and its working process is as follows:

[0018] 1. Filtration, sedimentation separation experiment: before the experiment starts, close each ball valve, heat the water in the water storage device (18) to a certain temperature, open each ball valve and water pump (35), and input the hot water into the sedimentation tank through the water delivery pipe (34) In the feed pipe (5) of (32), the oil sand flows in through the oil sand inlet (9), and the hot water on the feed pipe (5) top constantly washes the large sand grains filtered through the replaceable filter screen (6), and Clean and replace the replaceable filter (6) regularly. After removing the sandy oil with large sand grains and mixing it with hot water, the flow direction is changed through the through holes around the feed pipe (5), and slowly flows into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com