A kind of method and protective coating of nickel-free stainless steel coating hydroxyl graphene modified electrophoretic paint

A hydroxyl graphene and stainless steel technology, applied in electrophoretic coatings, coatings, anti-corrosion coatings, etc., can solve the problem of not being able to completely achieve nickel-free, improve chemical stability and solubility, avoid aggregation and precipitation, and improve corrosion resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

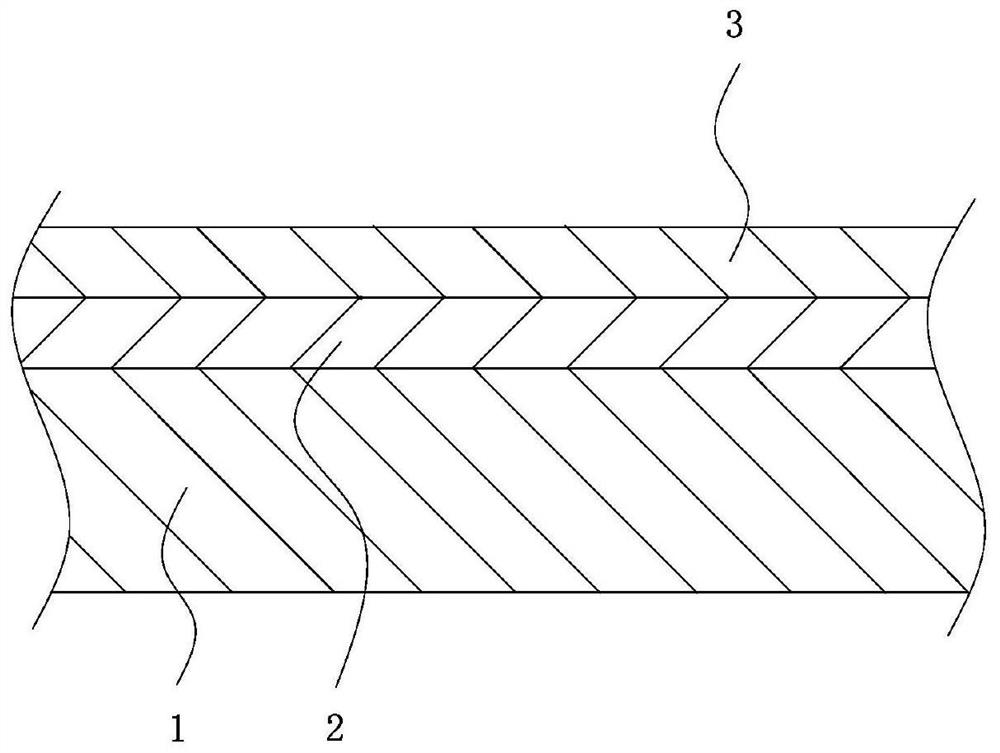

[0065] Such as figure 1 As shown, from bottom to top, it includes 0Cr13 stainless steel substrate, trivalent chromium white chrome coating 0.1 μm and hydroxyl graphene modified electrophoretic paint coating 8 μm;

[0066] The method of coating nickel-free stainless steel with hydroxygraphene modified electrophoretic paint is as follows:

[0067] After the surface of the 0Cr13 stainless steel substrate is drawn with a felt wheel wire drawing machine, the surface of the nickel-free stainless steel after wire drawing is sequentially subjected to alkaline chemical degreasing, water washing, alkaline cathode electrolytic degreasing, water washing, alkaline anode electrolytic degreasing, water washing, Cathodic electrolytic activation and washing to obtain pretreated nickel-free stainless steel; in the cathodic electrolytic activation, the nickel-free stainless steel after drawing is used as the cathode, and the graphite rod is used as the anode; the electrolyte is 100g / L sulfuric a...

Embodiment 2

[0072] Such as figure 1 As shown, from bottom to top, it includes 1Cr13 stainless steel substrate, trivalent chromium white chrome coating 0.15 μm and hydroxyl graphene modified electrophoretic paint coating 10 μm;

[0073] The method of coating nickel-free stainless steel with hydroxygraphene modified electrophoretic paint is as follows:

[0074] After the surface of the 1Cr13 stainless steel substrate is drawn with a felt wheel wire drawing machine, the surface of the nickel-free stainless steel after wire drawing is sequentially subjected to alkaline chemical degreasing, water washing, alkaline cathode electrolytic degreasing, water washing, alkaline anode electrolytic degreasing, water washing, Cathodic electrolytic activation and washing to obtain pretreated nickel-free stainless steel; in the cathodic electrolytic activation, the nickel-free stainless steel after wire drawing is used as the cathode, and the graphite rod is used as the anode; the electrolyte is 180g / L sul...

Embodiment 3

[0079] Such as figure 1 As shown, from bottom to top, it includes 2Cr13 stainless steel substrate, trivalent chromium black chrome coating 0.07μm and hydroxyl graphene modified electrophoretic paint coating 15μm;

[0080] The method of coating nickel-free stainless steel with hydroxygraphene modified electrophoretic paint is as follows:

[0081] After the surface of the 2Cr13 stainless steel substrate is drawn with a felt wheel wire drawing machine, the surface of the nickel-free stainless steel after wire drawing is sequentially subjected to alkaline chemical degreasing, water washing, alkaline cathode electrolytic degreasing, water washing, alkaline anode electrolytic degreasing, water washing, Cathodic electrolytic activation and washing to obtain pretreated nickel-free stainless steel; in the cathodic electrolytic activation, the nickel-free stainless steel after wire drawing is used as the cathode, and the graphite rod is used as the anode; the electrolyte is 150g / L sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com