Wall skin cleaning device for decoration

A technology for cleaning devices and wall coverings, which can be used in building maintenance, construction, building construction, etc., and can solve problems such as threats to workers' health, low work efficiency, and uneven walls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

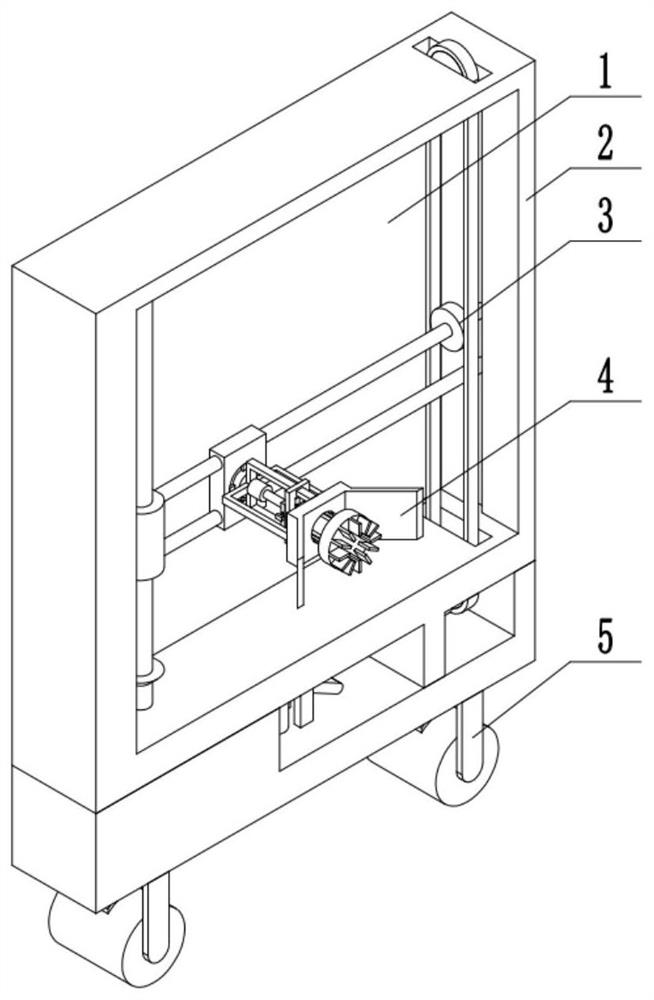

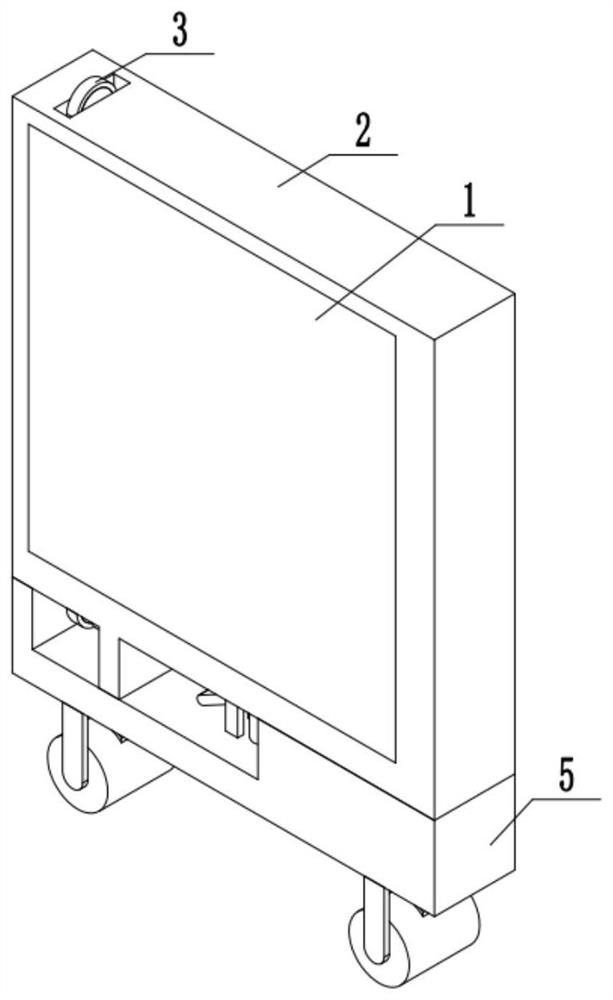

[0037] Combine below figure 1 , 2 Description of this embodiment, a wall skin cleaning device for decoration, including a movable rear panel 1, a mounting frame body 2, a driving device 3, a cleaning device 4 and a moving device 5, and the movable rear panel 1 is movably installed on the mounting frame body 2, a driving device 3 is installed on the mounting frame body 2, the cleaning device 4 is installed on the driving device 3, and the moving device 5 is fixedly installed on the mounting frame body 2.

specific Embodiment approach 2

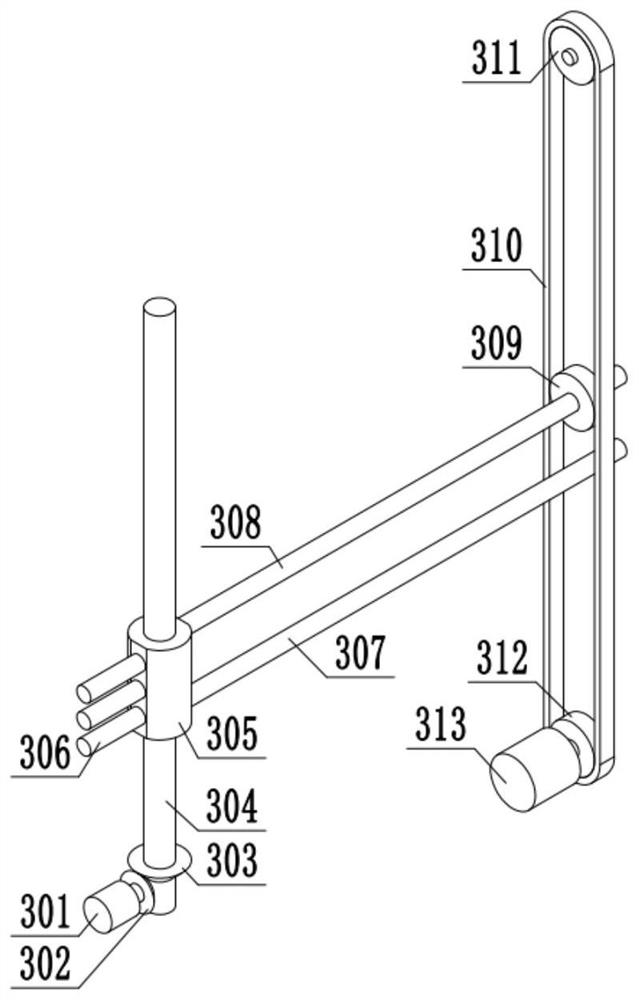

[0039] Combine below image 3 , 4 Describe this embodiment, this embodiment will further explain the first embodiment, the driving device 3 includes a power motor A301, driving bevel gear A302, driving bevel gear B303, driving screw rod A304, driving threaded sleeve 305, limiting slide bar 306, Guide bar 307, driving screw rod B308, driving pulley 309, driving belt 310, support pulley 311, driving pulley 312, power motor B313, the output end of power motor A301 is equipped with driving bevel gear A302, driving bevel gear A302 and driving bevel The gear B303 is meshed with the teeth, and the driven bevel gear B303 is fixedly installed on the driven screw rod A304, and the driven screw rod A304 is movably installed on the mounting bracket body 2, and the driven threaded sleeve 305 is installed on the driven screw rod A304, and the driven threaded sleeve 305 is fixedly installed with Restricting slide bar 306, guide rod 307 sliding installation is driven thread sleeve 305, is in...

specific Embodiment approach 3

[0041] Combine below Figure 5 , 6 , 7, 8, 9, 10, 11, 12, and 13 illustrate this embodiment, and this embodiment will further explain Embodiment 1. The described cleaning device 4 includes a fixed block 401, a driving mechanism 402, a cleaning mechanism 403, an adjustment Mechanism 404, driving mechanism 402 is installed on the fixed block body 401, driving mechanism 402 is installed on the cleaning mechanism 403, adjusting mechanism 404 is installed on the driving mechanism 402, and cleaning mechanism 403 is fixedly installed on the adjusting mechanism 404;

[0042] The driving mechanism 402 includes a control block 405, a driving column 406, a block 407, a fixed cross 408, a power motor C409, an adjusting screw 410, and a driving gear 411. The control block 405 is fixedly installed on the driving column 406, and the driving column 406 The block 407 is fixedly installed, the driving column 406 is movably installed on the fixed block 401, the fixed cross 408 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com