Plug conveying positioning control system and method of automatic transplanting machine

A technology for tray transportation and positioning control, applied in planting methods, transplanting machinery, applications, etc., can solve problems such as being easily affected by dust and light, unstable operations, and inaccurate positioning, so as to improve transplanting efficiency and success High efficiency, good anti-interference ability and stability, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

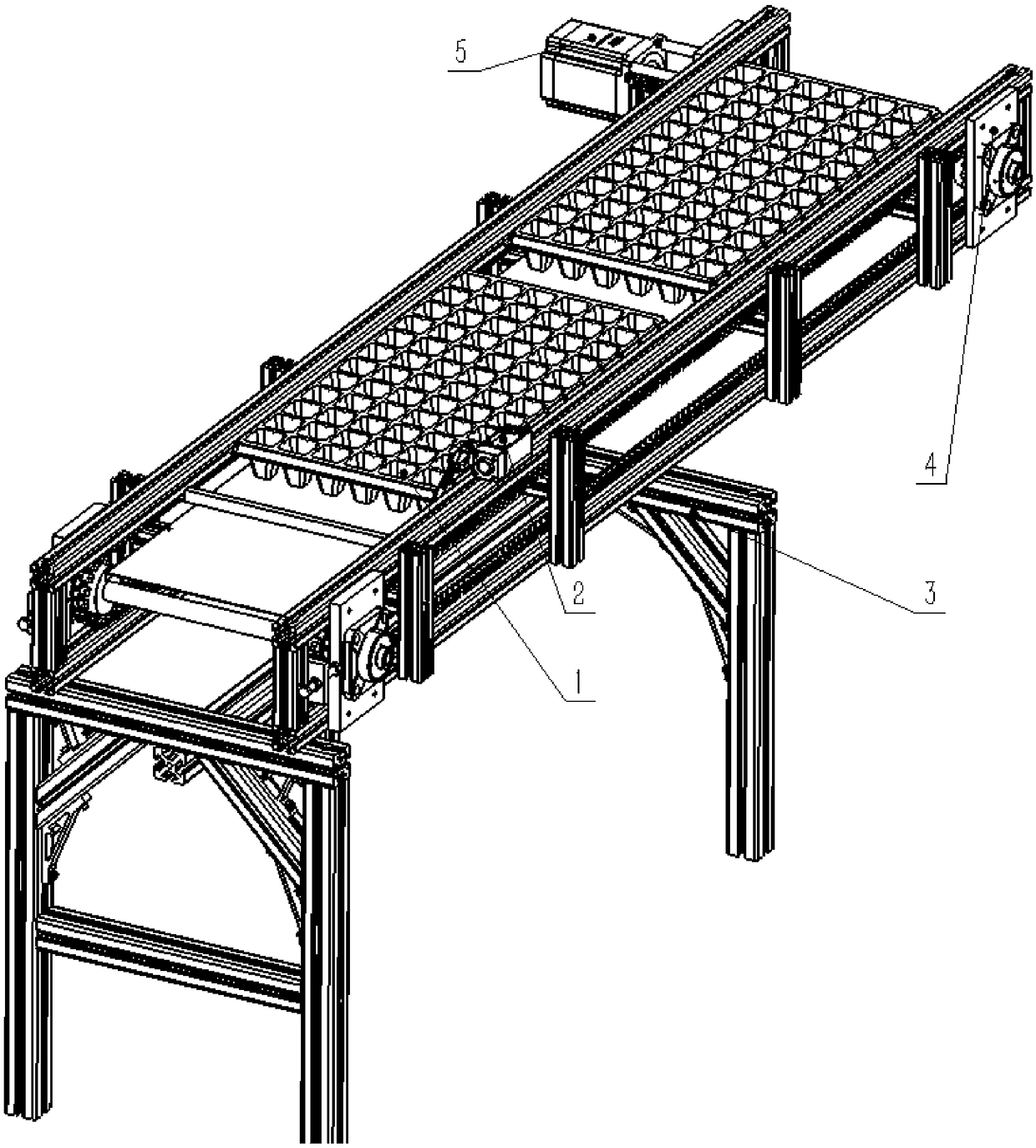

[0040] An automatic transplanting machine tray delivery positioning control system, comprising an operation interface, a tray delivery device and a programmable controller; the programmable controller controls the tray delivery device through the operation interface;

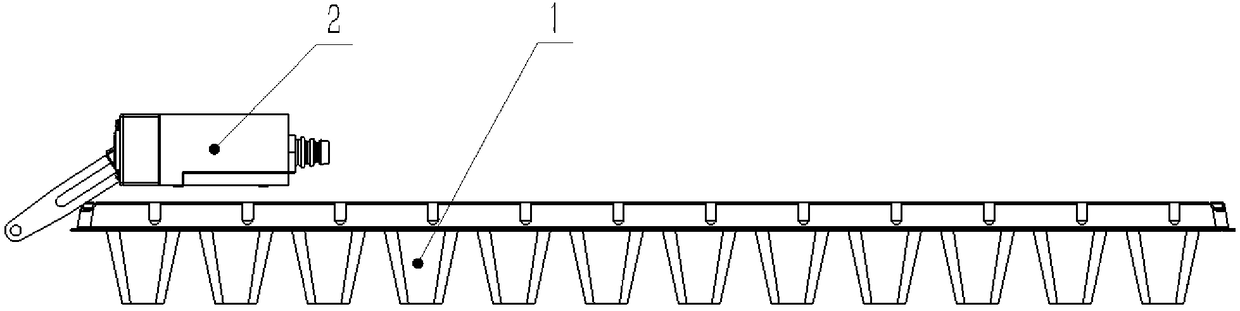

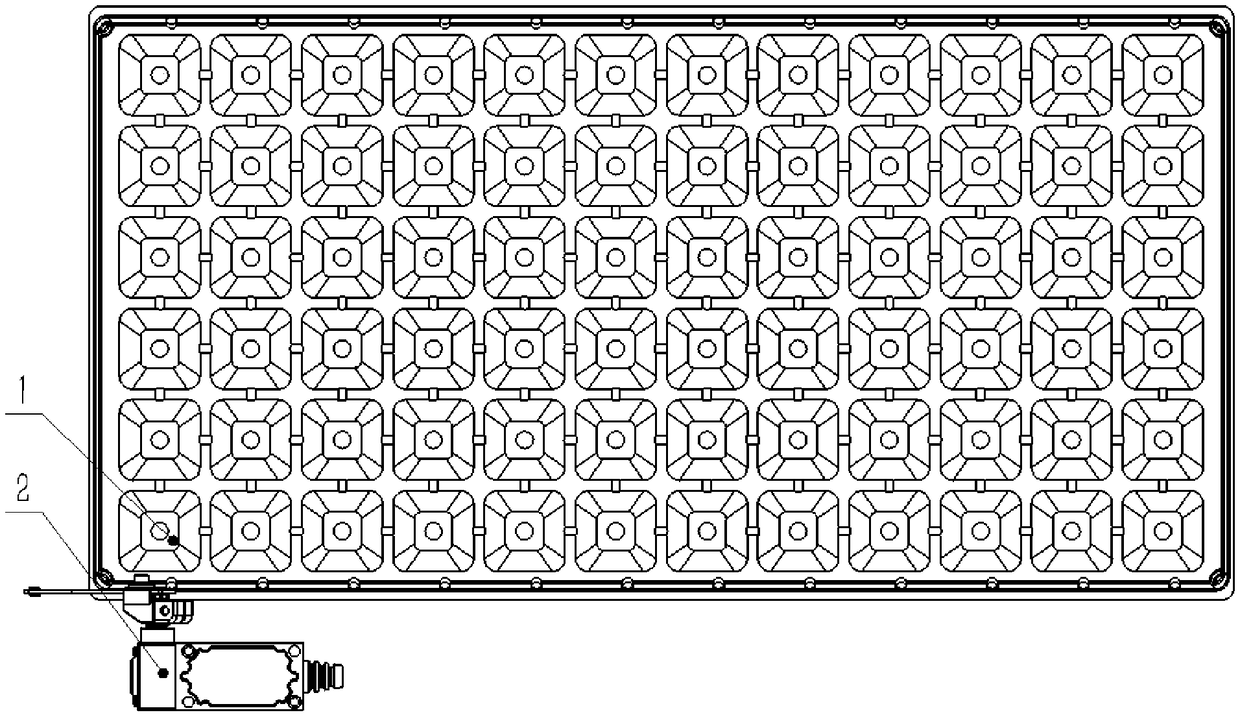

[0041] The operation interface includes a start button, a stop button, a slight increase button, a slight decrease button, a hole plate switching button, a manual button and an automatic button; the start button and the stop button are used to control the start and stop of the stepper motor 5; The micro-increase button and the micro-decrease button are used to adjust the accuracy of the initial plate feeding, and are used to realize the fine adjustment of the stepper motor 5 to the position of the tray 1, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com