Slide making assembly for horizontal centrifugal liquid-based thin-layer cell machine

A thin-layer cell and centrifugal technology, which is applied in the field of tablet components for horizontal centrifugal liquid-based thin-layer cell machines, can solve the problem of not being able to perfectly fit the horizontal centrifugal liquid-based thin-layer cell machine, etc. Effects of sexual infections, increased efficiency, and occupational exposure avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

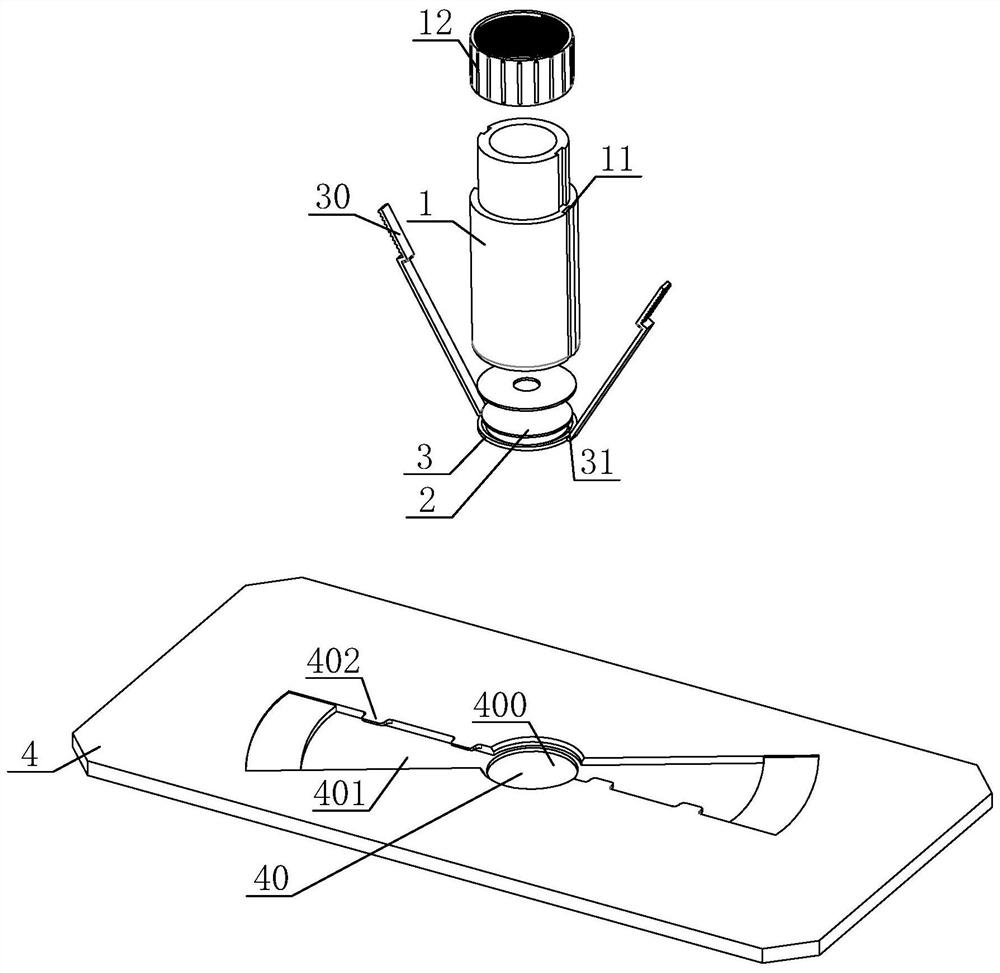

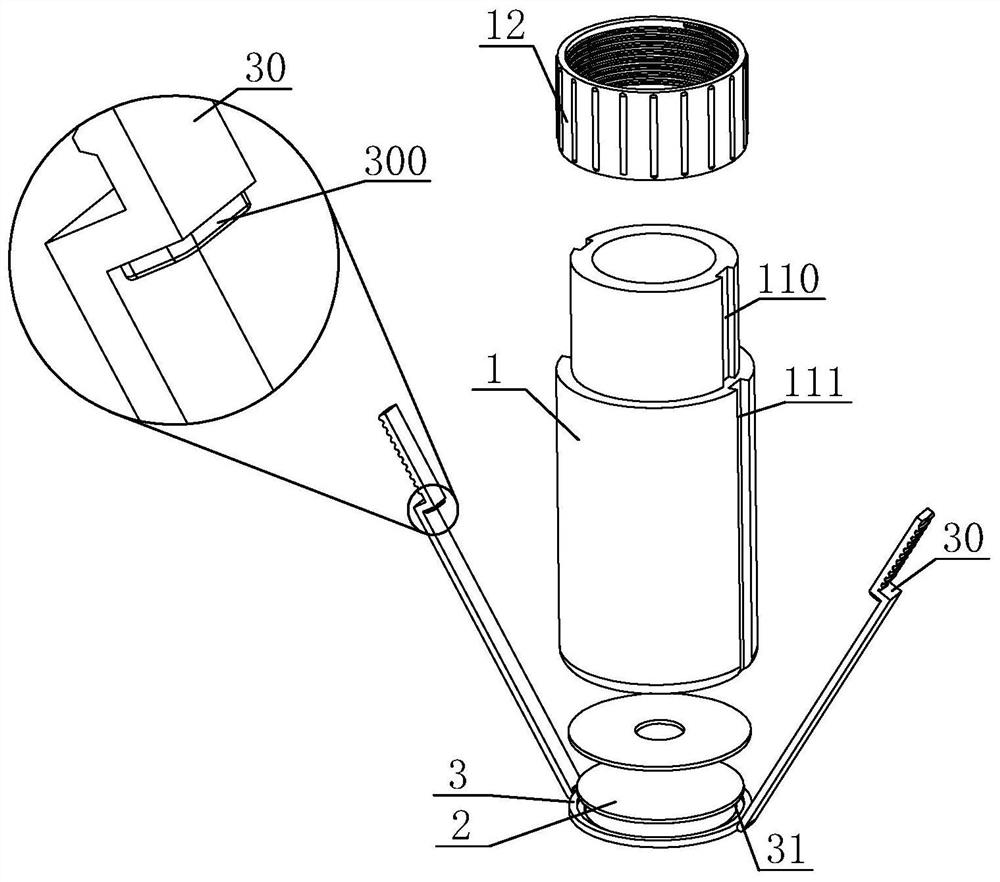

[0043] 1. Put the glass slide 2 into the first fixing slot, and press the container 1 against the slide 2.

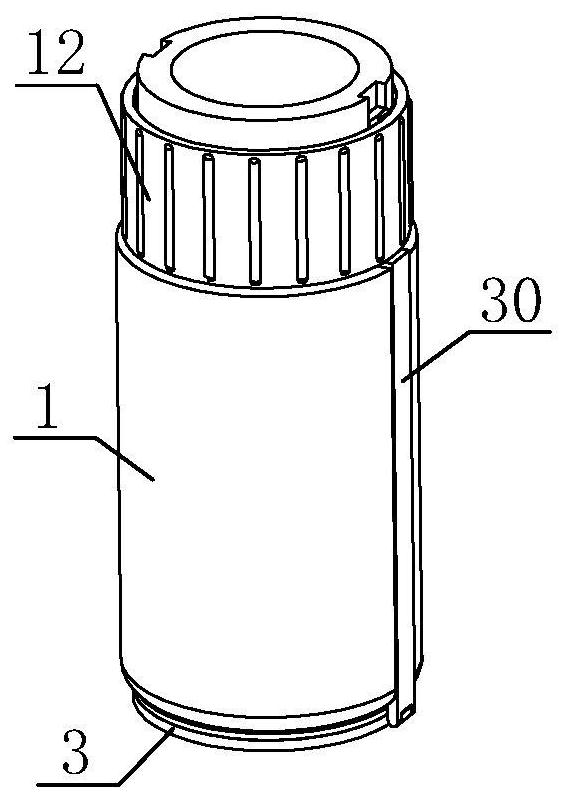

[0044] 2. Attach the container 1 to the fastener 3 , and the clamping arm 30 clamps the fitting clamping groove 11 upward.

[0045] 3. At this time, rotate and tighten the fixed cap 12 and the clamp arm 30, the clamp arm 30 firmly clamps the container 1, and puts it into a horizontal centrifugal liquid-based thin-layer cell machine.

[0046] 4. The horizontal centrifugal liquid-based thin-layer cell machine starts to work, and the container 1 is centrifuged, and the tissue slurry inside moves toward the opening side of the container 1, and the sample stays in the middle of the slide 2.

[0047] 5. After the centrifugation is completed, all the samples to be observed remain on the glass slide 2, the fixing cap 12 is removed, and the clamp arm 30 is opened.

[0048] 6. Put the clamp arm 30 into the slide glass 4, and rotate it until it snaps into the limit protrusion 402, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com