A device and method for preparing a foreign object damage gap of a blade leading edge simulation part

A technology for the leading edge of a blade and a preparation device, which is applied in the field of aero-engines, can solve problems such as reducing the dispersion of results, and achieve the effects of reducing the dispersion, a reliable preparation method, and an increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The invention will be described in more detail below in conjunction with the accompanying drawings.

[0053]As shown in the figure, the main problem to be solved by the present invention is the problem of notch preparation.

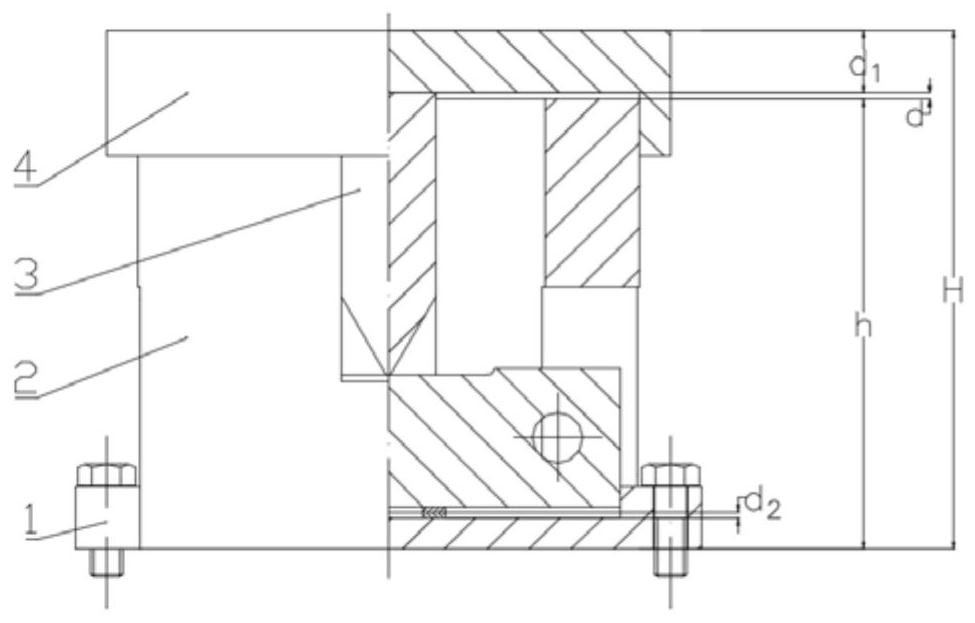

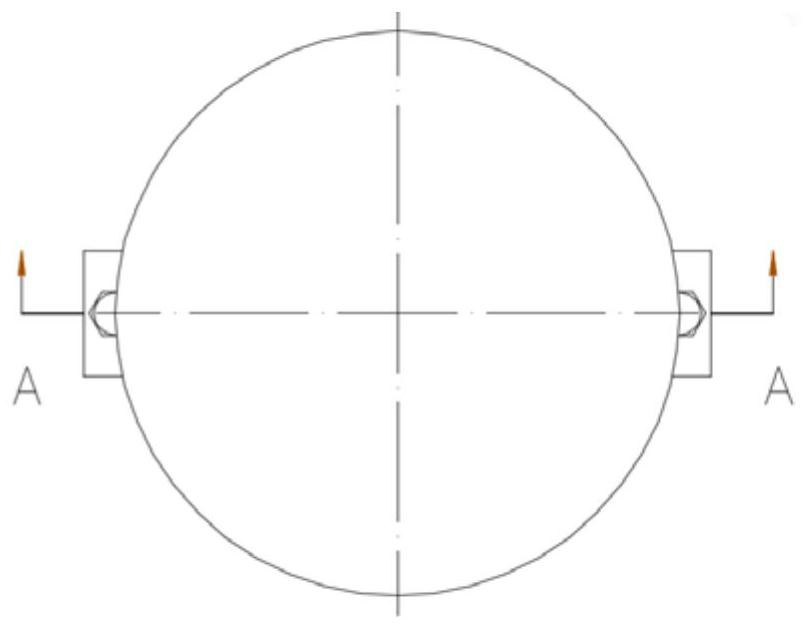

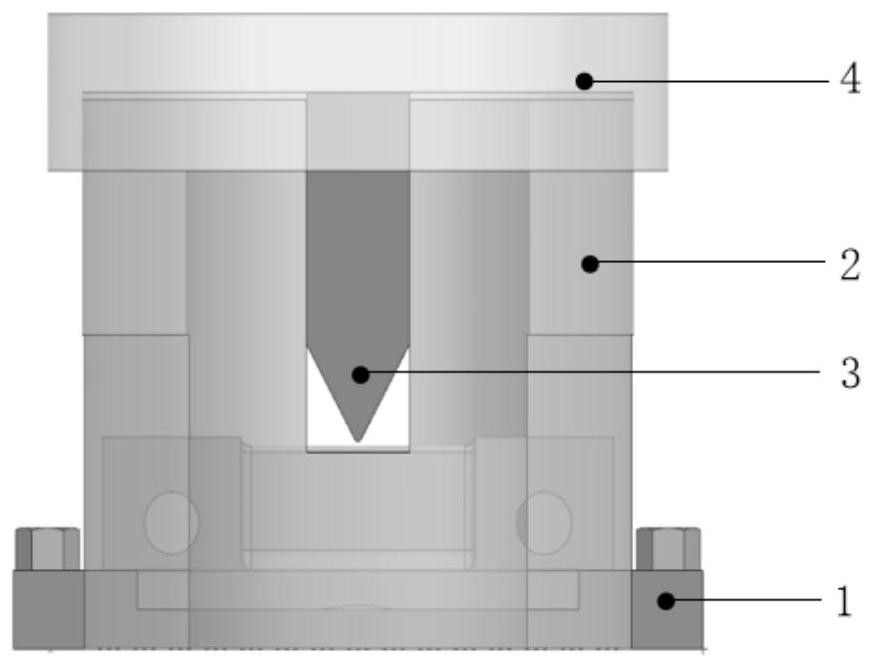

[0054] In the actual preparation process, the structure of the whole set of instruments is as follows: Figure 1-9 As shown, it consists of four main components: a positioning fixture 1, a cylindrical seat 2, a pressure head 3, and a pressure plate 4.

[0055] When preparing the foreign object damage gap of the blade leading edge simulation part, first use bolts to fix the positioning fixture 1 on a firm test bench, and then snap the test piece into the designed groove of the positioning fixture 1 to ensure the stability of the test piece, and then The positioning fixture 1 is fixed to the cylindrical seat 2 by using two relatively downward slots of the cylindrical seat to ensure its stability, and then put the indenter 3 into the two upward slots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com