Contact network flaw detection system

A technology of flaw detection and catenary, which is applied in the direction of radio wave measurement system, signal transmission system, satellite radio beacon positioning system, etc., can solve the problems of inability to detect the internal damage of the catenary, catenary flaw detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

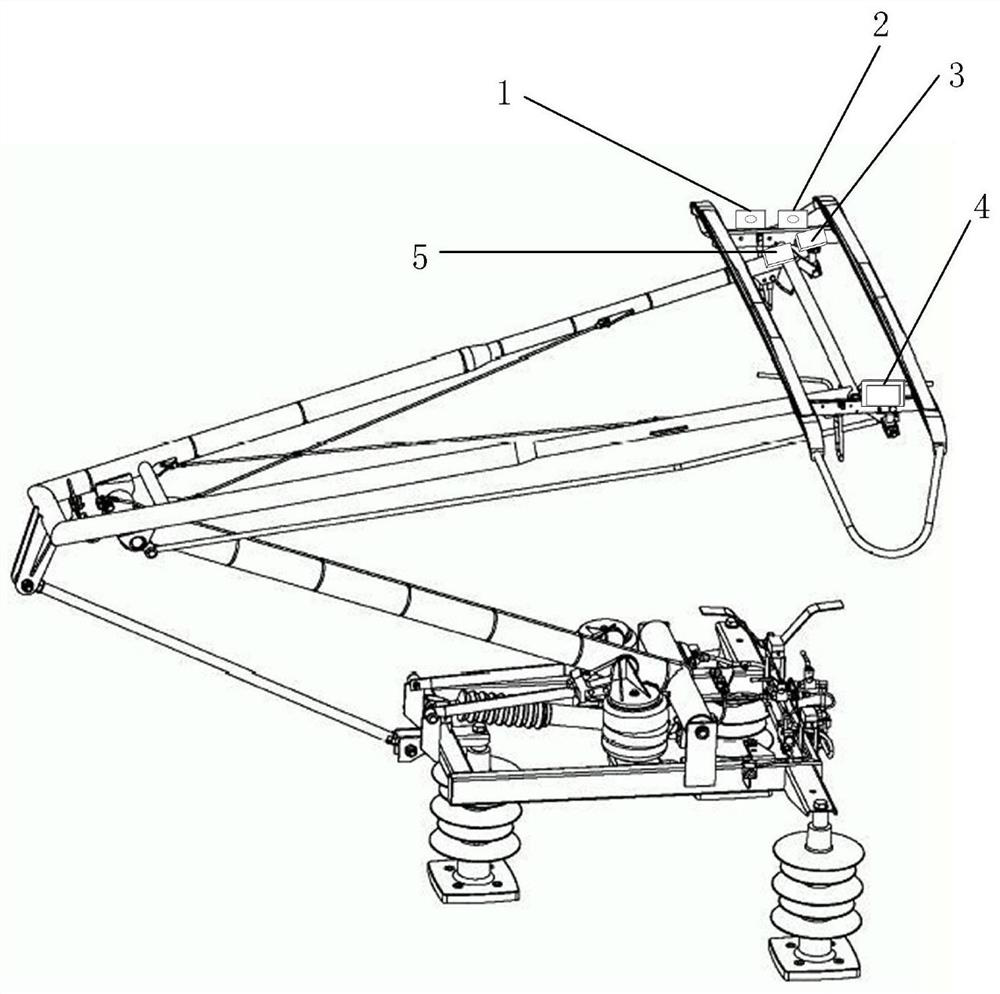

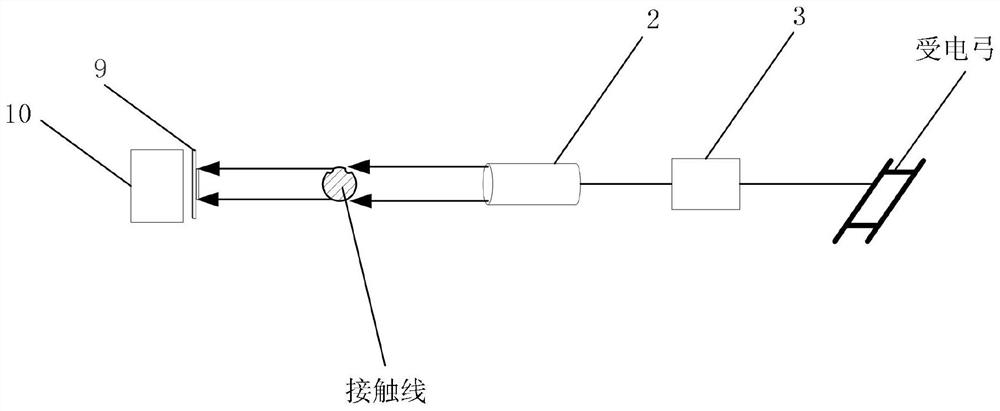

[0021] see Figure 1 to Figure 4 , a catenary flaw detection system in the present invention includes a laser imaging radar 1 , an X-ray emitter 2 , a booster 3 , an X-ray receiver 4 , and a control circuit board 5 .

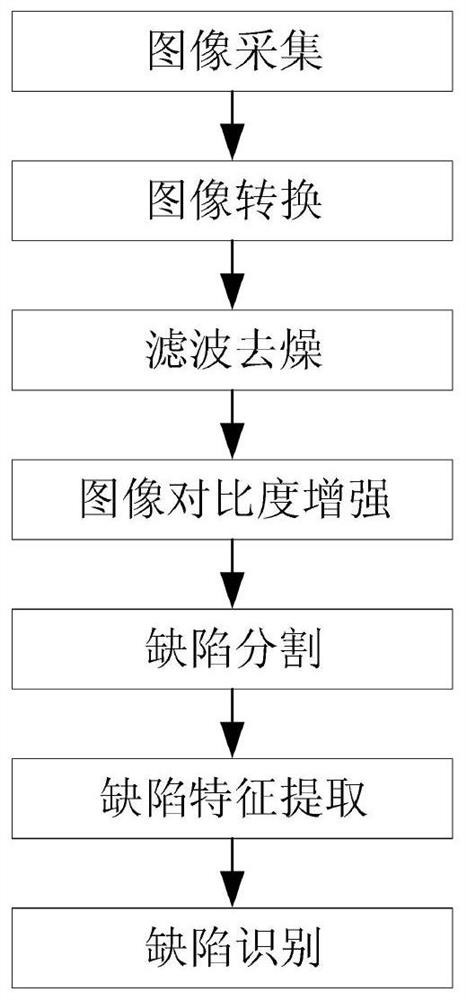

[0022] Such as figure 1 As shown, the laser imaging radar 1, X-ray transmitter 2, booster 3, and control circuit board 5 are installed on one end of the pantograph head, and the X-ray receiver 4 is installed on the other end of the pantograph head At one end, the laser imaging radar 1 emits a laser beam to the contact line for scanning, and receives the laser radiation reflected by the contact line to generate continuous analog signals, which are restored to real-time contact line images, and these analog signals are converted in the control circuit board 5 Calculate the height of the contact line in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com