Control method of hanging bag type logistics system

A technology of a logistics system and a control method, applied in the field of light industrial washing machinery and equipment, can solve problems such as unsmooth logistics and affect production efficiency, and achieve the effect of improving production efficiency and improving automation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

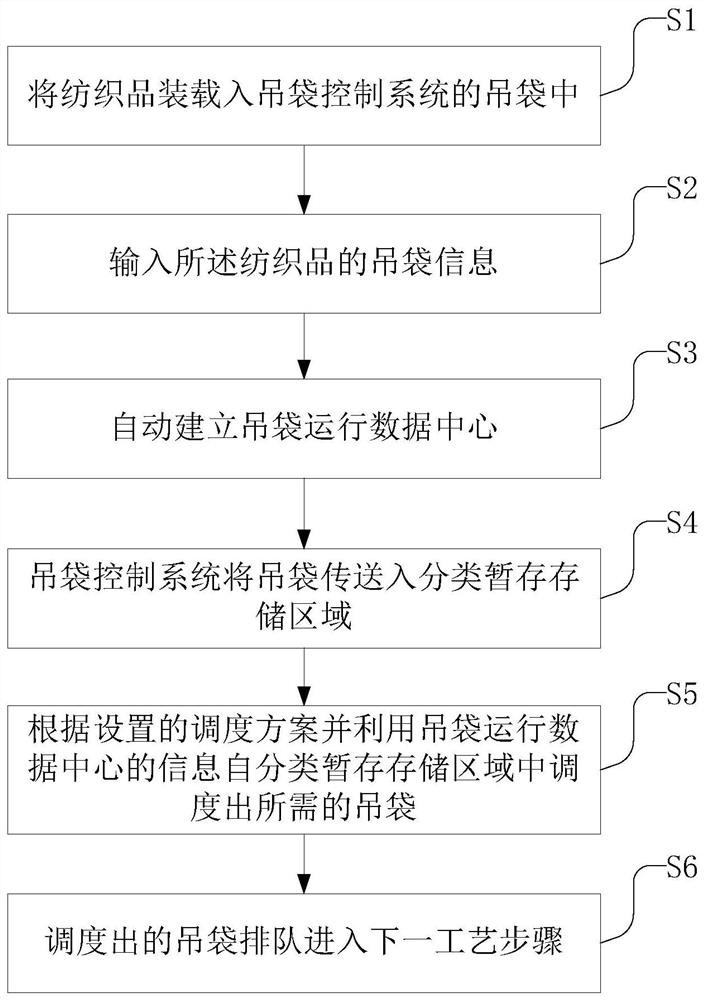

[0020] According to the attached figure 1 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0021] see figure 1 , a method for controlling a hanging bag logistics system according to an embodiment of the present invention, comprising the steps of:

[0022] S1: Load the textiles into the hanging bag of a hanging bag control system. The hanging bag control system includes a computer control system, a PLC centralized controller, a DeviceNet bus, multiple remote control modules and multiple remote detection actuator groups , the computer control system is connected to the PLC centralized controller, the PLC centralized controller is connected to the remote control module through the DeviceNet bus, each remote control module is connected to a remote detection execution device group, and the remote detection execution device group includes a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com