Double-frame BIPV photovoltaic roof tile and grounding method of double-frame BIPV photovoltaic roof tile

A roof tile and photovoltaic panel technology, which is applied to the support structure of photovoltaic modules, roofs, photovoltaic modules, etc., can solve the problem of high installation cost, and achieve the effect of low grounding installation cost and high grounding reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

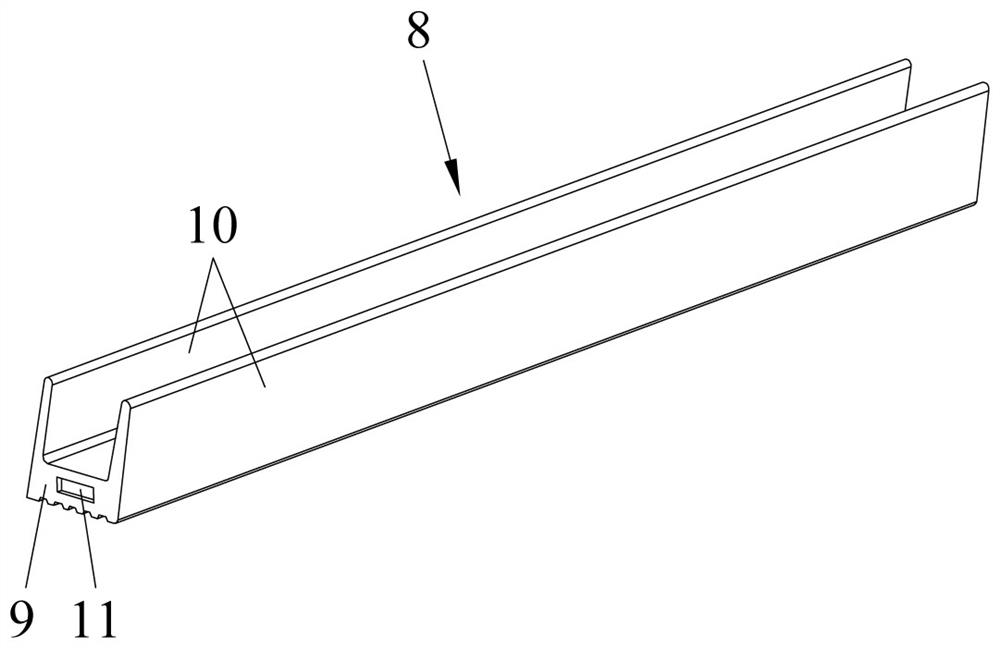

[0033] Embodiment one: as attached Figures 3 to 5 As shown, a conductive resistive glue strip 8 suitable for double-frame BIPV products includes a strip-shaped body and a continuous conductor 11 disposed in the body.

[0034] Specifically, the conductive resistance water glue strip 8 can be suitable for flat double-frame BIPV products such as the attached image 3 The shown planar conductive resistive water glue strip 8, that is, the axis of its body is a straight line, can also be applied to curved surface double-frame BIPV products such as attached Figure 4 The shown curved surface type conductive resistive glue strip 8, that is, the axis of its body is a curve.

[0035] The body of the conductive resistive glue strip 8 includes a strip-shaped insulating packaging material part 9, several water-retaining bosses 10 arranged on the upper surface of the insulating packaging material part 9, and the conductor 11 is arranged in the insulating packaging material part 9, namely ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap