Optical articles having embossed films defining encapsulated microlenses and methods of making the same

A technology of optical products and optical layers, applied in the directions of optics, optical components, optical components, etc., can solve the problems that the coating cannot provide sufficient protection, change the optical design of optical components, change the geometric shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

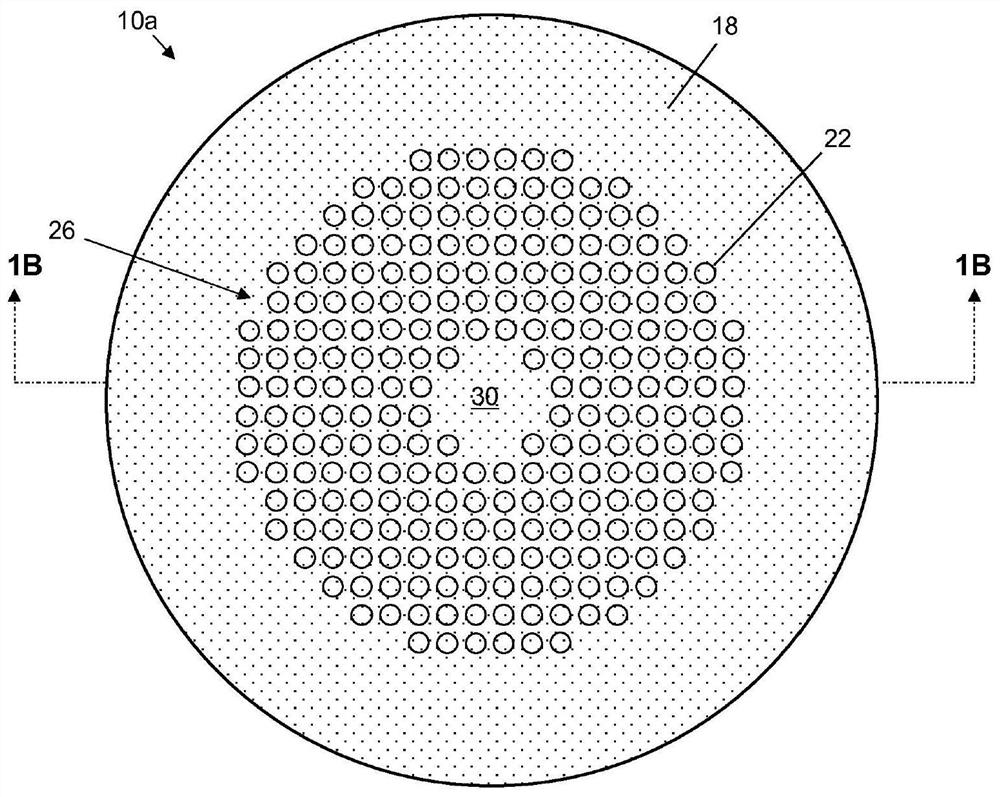

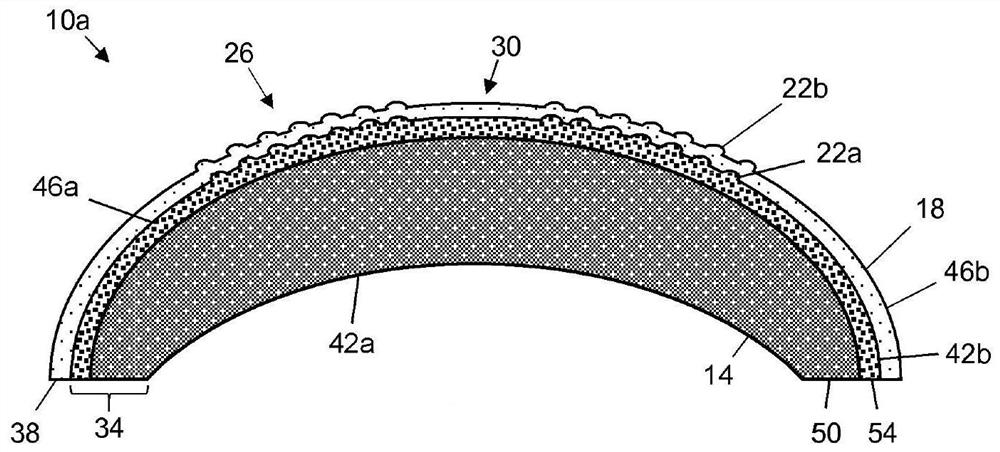

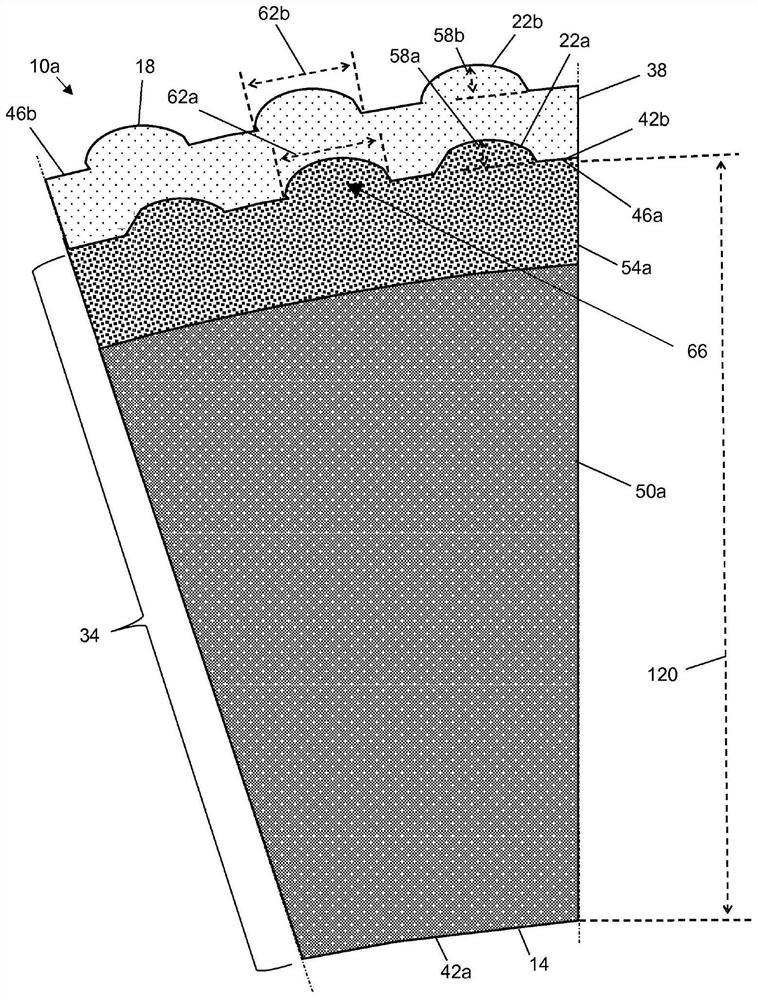

[0029] refer to Figure 1A to Figure 1C, shows a first embodiment 10a of the optical article of the present invention. Optical article 10a can include primary optical layer 34 having opposing first and second primary optical surfaces 42a and 42b and film layer 38 having opposing first and second film surfaces 46a and 46b. Optical article 10a may have any suitable shape; for example, the optical article may be spherical, toric, or aspheric. To illustrate, optical article 10a may have inner surface 14 defined, for example, by first primary optical surface 42a and outer surface 18, for example defined by second film surface 46b. Inner surface 14 may be concave and outer surface 18 may be convex; however, in other embodiments, each of the inner and outer surfaces may be concave, convex, or flat, which Depends on the intended use of the optical article 10a.

[0030] Film layer 38 may be embossed such that first film surface 46a defines a plurality of concave optical elements 22a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com