Heat preservation greenhouse structure capable of efficiently utilizing energy

A high-efficiency technology for thermal insulation greenhouses, which is applied in the fields of renewable energy machines, applications, greenhouse cultivation, etc., can solve the problems of unreasonable utilization of energy in thermal insulation greenhouses, and achieve the effects of easy popularization, convenient operation, and convenient effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

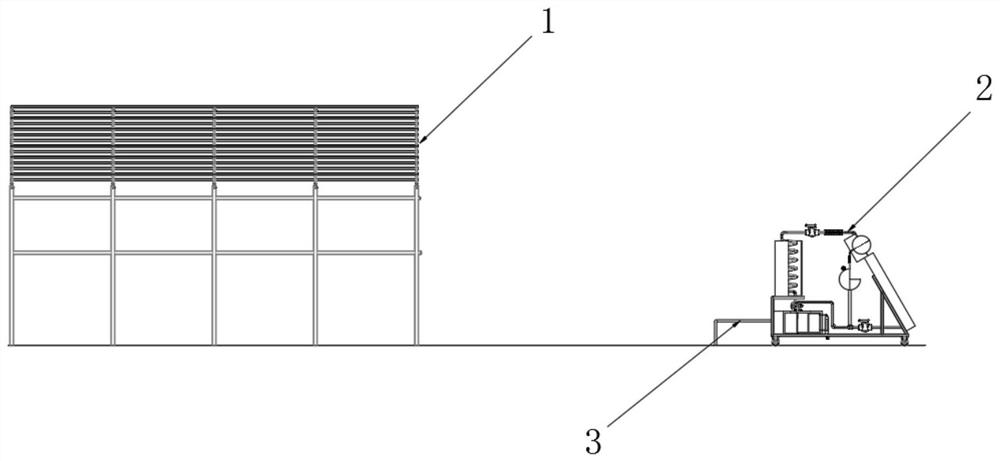

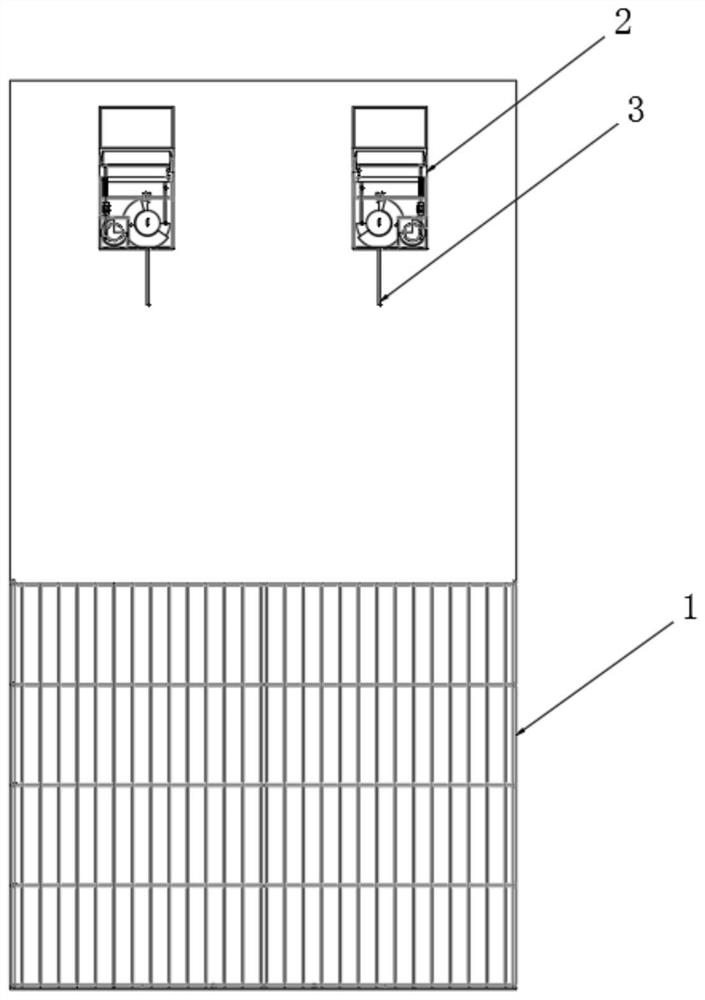

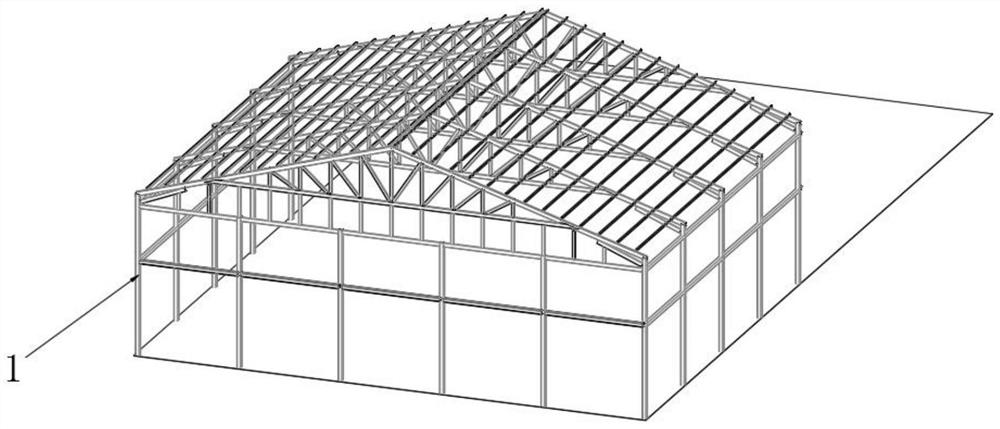

[0027] Such as Figure 1-5 As shown, a thermal insulation greenhouse structure for efficient energy utilization includes a shed structure 1, a solar water heater 2, a connecting pipe 3, a temperature-conducting pipe 18, and a control device, wherein: the shed structure 1 includes a shed body and a covering body , the shed structure 1 is provided with at least one inlet and outlet, and the temperature-conducting pipe fitting 18 is buried below the ground covered by the shed structure 1, and the covering body can be a plastic film body or a glass part; the temperature-conducting pipe fitting 18 Including a water inlet port 19 and a water outlet port 20, the water inlet port 19 and the water outlet port 20 are respectively connected with a connecting pipe 3, the inside of the temperature conducting pipe 18 is provided with a temperature sensor; one end of the connecting pipe 3 is inserted into the ground Below, the other end is located above the ground, the connecting pipe 3 is c...

Embodiment 2

[0030] On the basis of the above embodiments, in order to enhance the efficient utilization of energy, the following improvements are made here, such as Figure 6-10 As shown, the covering part of the shed structure 1 is a heat-insulating glass part 6, and the interior of the shed structure 1 is provided with a light source. The shed structure 1 is composed of several groups of square members, the square members include a vertical bar 4 and a horizontal bar 5, and the heat-insulating glass 6 is arranged between the horizontal bar 5 and the vertical bar 4 . The vertical bar member 4 includes a first card slot 14 and a glass channel 15, the inside of the first card slot 14 is fixedly connected with a fixed rod member 11, and the outer surface of the fixed rod member 11 is fixedly connected with a telescopic bag member 12 The other end of the telescoping bag 12 is fixedly connected with a moving rod 10, the outer surface of the vertical bar 4 is fixedly connected with an air pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com