Method and device for measuring levelness of medical imaging equipment, medical imaging equipment and mold body

A technology of medical imaging and levelness, applied in the field of medical imaging, can solve the problems of accuracy limitation and indirect measurement method, and achieve the effect of reducing dose, improving accuracy and quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

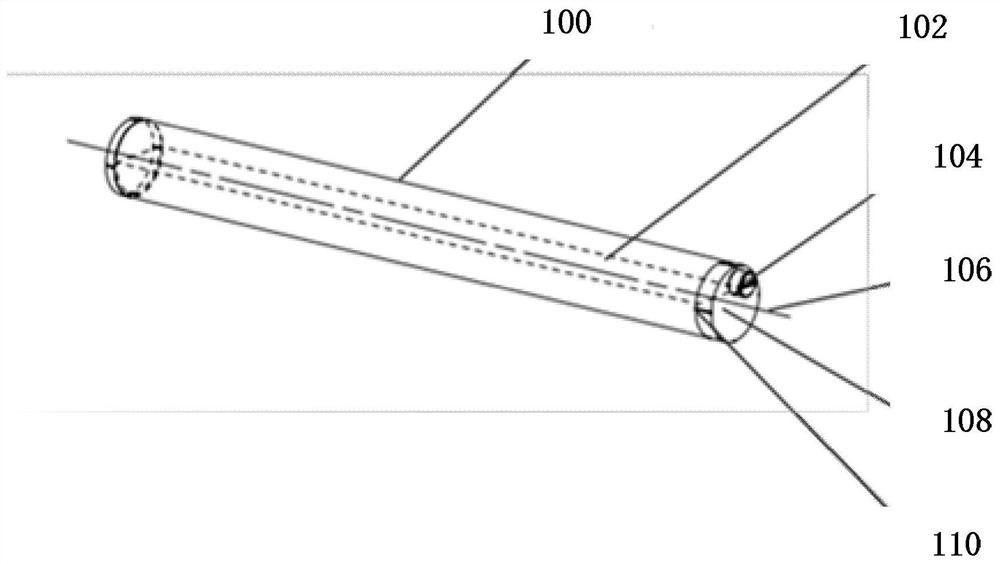

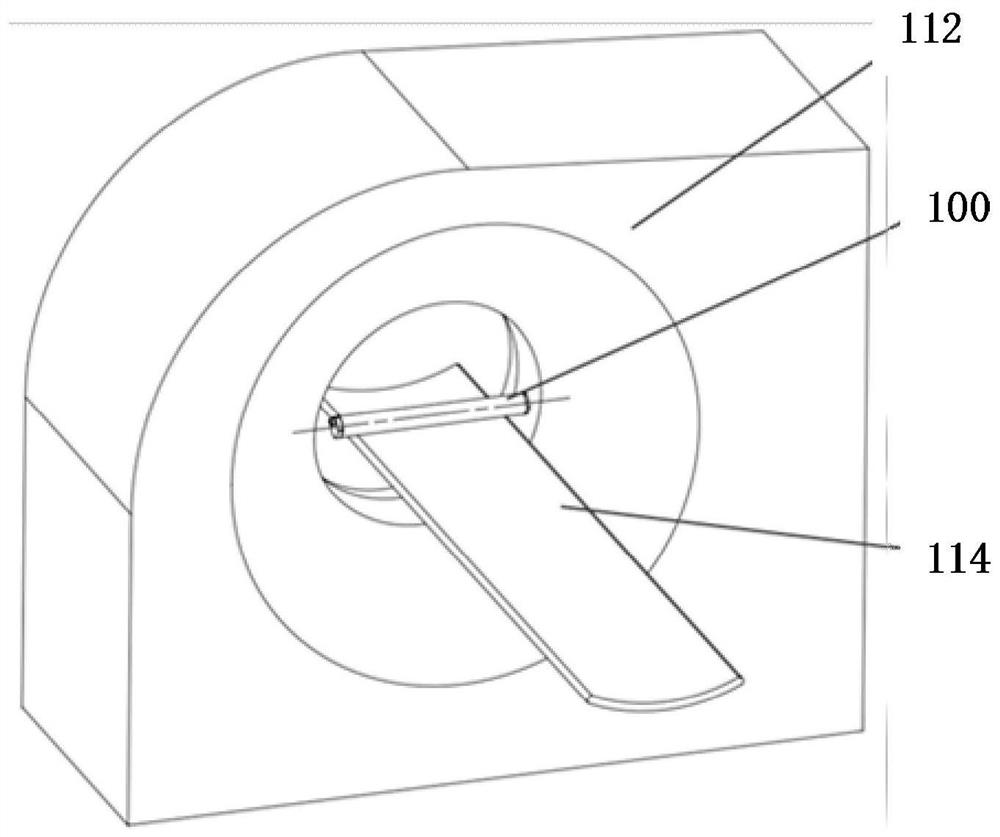

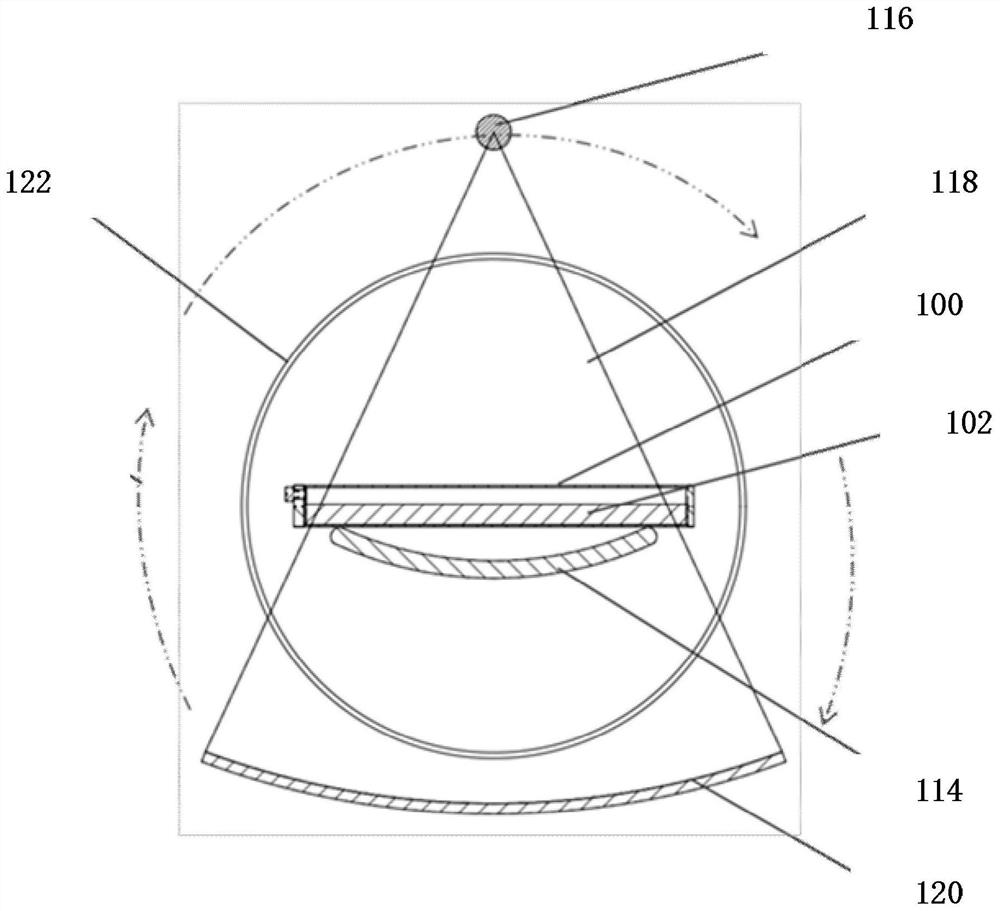

[0041] figure 1 is a schematic diagram of a phantom 100 according to an embodiment of the present invention. The mold body 100 includes a cylindrical body 102 , two end caps 108 , and an opening 104 . The cylindrical body 102 is made of plastic, in this embodiment polymethyl methacrylate. The length of the cylindrical body 102 in the longitudinal direction is larger than the scanning area to eliminate the influence of the end. Two end caps 108 are fixed on both ends of the cylindrical body 102 and form a cylindrical accommodation space with the cylindrical body 102 . The cylindrical accommodation space and the cylindrical body 102 have the same rotation axis 106 . End cap 108 may also be made of plastic such as polymethyl methacrylate. The opening 104 is located on the end cap 108 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com