Rotary mechanism for automatic testing of computer devices

An automatic detection and slewing mechanism technology, which is applied in the direction of instruments, measuring devices, and optical devices, can solve problems such as detecting gaps, and achieve the effects of saving costs, shortening no-load time, and saving work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

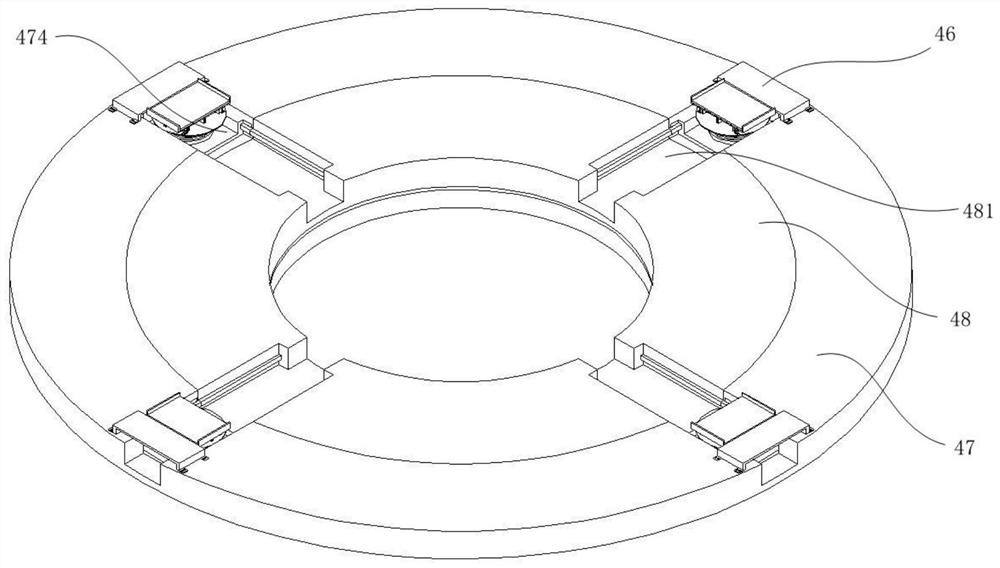

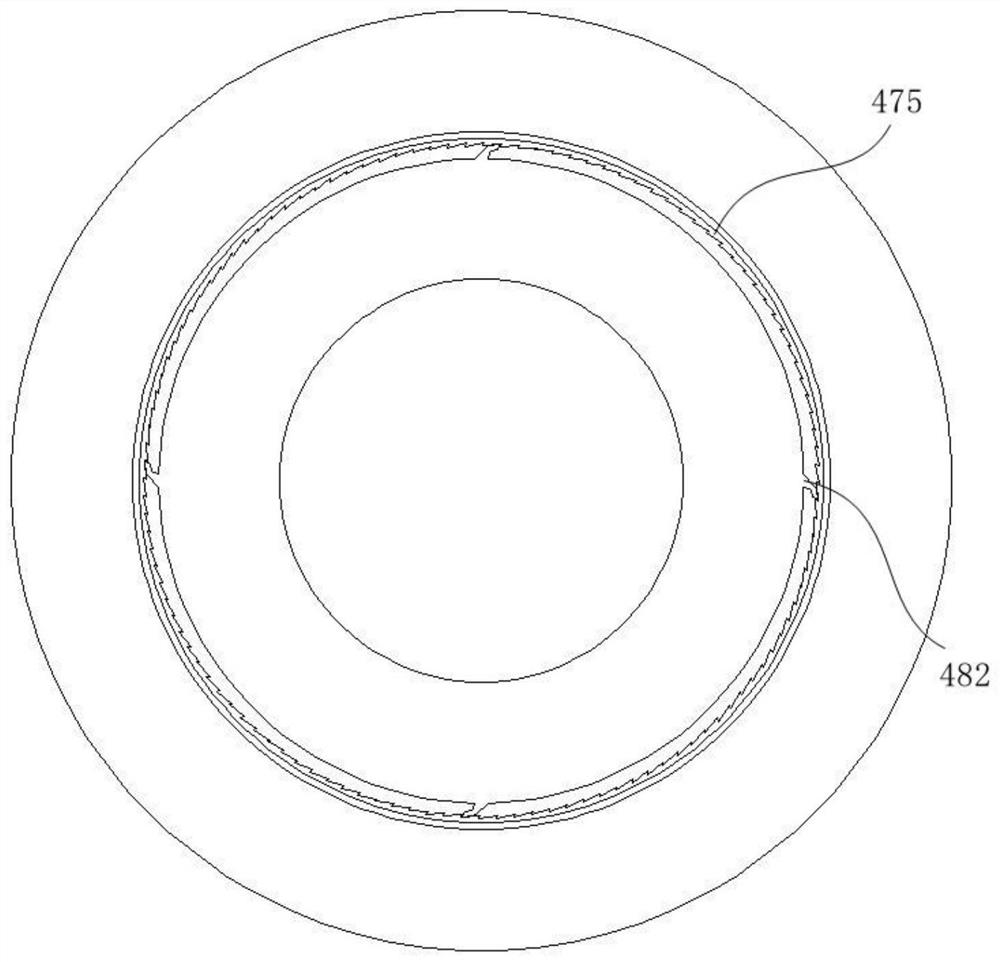

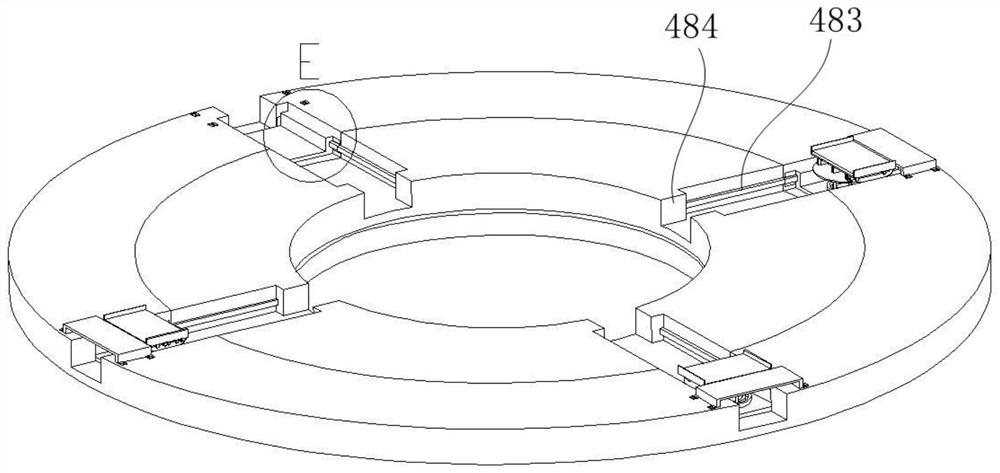

[0038] like Figures 1 to 8 As shown, a rotary mechanism for automatic detection of computer devices includes a first rotary mechanism 4 and a second rotary mechanism 5 arranged horizontally, and the first rotary mechanism 4 and the second rotary mechanism 5 are in the direction along the conveyor belt assembly 2. When connected, the transfer of the computer device to be detected can be realized. The first rotary mechanism 4 includes a first rotary table 47 and a second rotary table 48 that are rotatably connected, a number of material transport mechanisms 46 that can move back and forth along the end face of the rotary mechanism, and are arranged on The second push-pull mechanism in the middle of the first rotary mechanism 4, the first turntable 47 and the second turntable 48 can be driven by the second turntable 48 to rotate the first turntable 47 synchronously, or the first turntable 47 can be accelerated Rotating and the rotation speed of the second turntable 48 is constan...

Embodiment 2

[0050] like Figures 1 to 14 As shown, this embodiment specifically applies the rotary mechanism of Embodiment 1 to the detection of computer hard disks, and forms a computer hard disk batch detection equipment, which is provided with a conveyor belt assembly 2 in addition to the rotary mechanism in Embodiment 1. 2. The first push-pull mechanism 3 is arranged on one side of the conveyor belt assembly 2, and the first rotation mechanism 4 is arranged on the other side of the conveyor belt assembly 2 relative to the first push-pull mechanism 3, and the second rotation mechanism 5 is arranged on the first push-pull mechanism 3. A rotary mechanism 4 is in the direction of the conveyor belt assembly 2, and the first rotary mechanism 4 and the second rotary mechanism 5 are connected in the direction of the conveyor belt assembly 2, which can realize the transfer of the hard disk to be tested.

[0051] In this embodiment, the first push-pull mechanism 3 is fixed to one side of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com