Dotting machine

A dotting machine and machine body technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low production efficiency and achieve the effect of improving processing efficiency and continuous supply efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

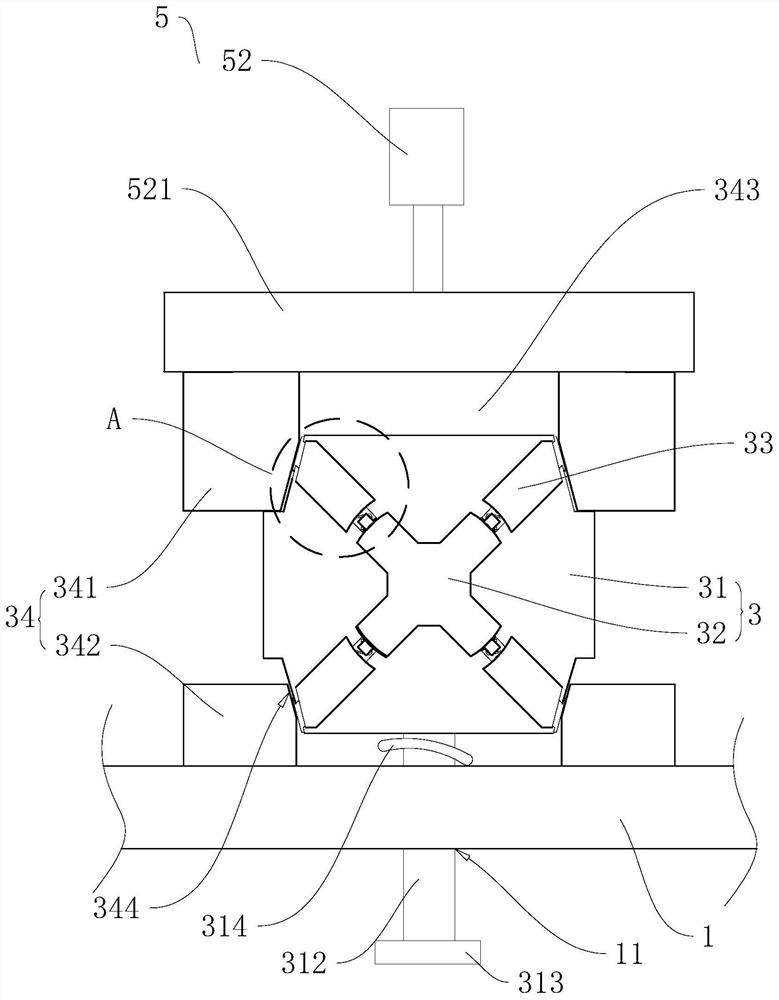

[0039] The following is attached Figure 1-7 The application is described in further detail.

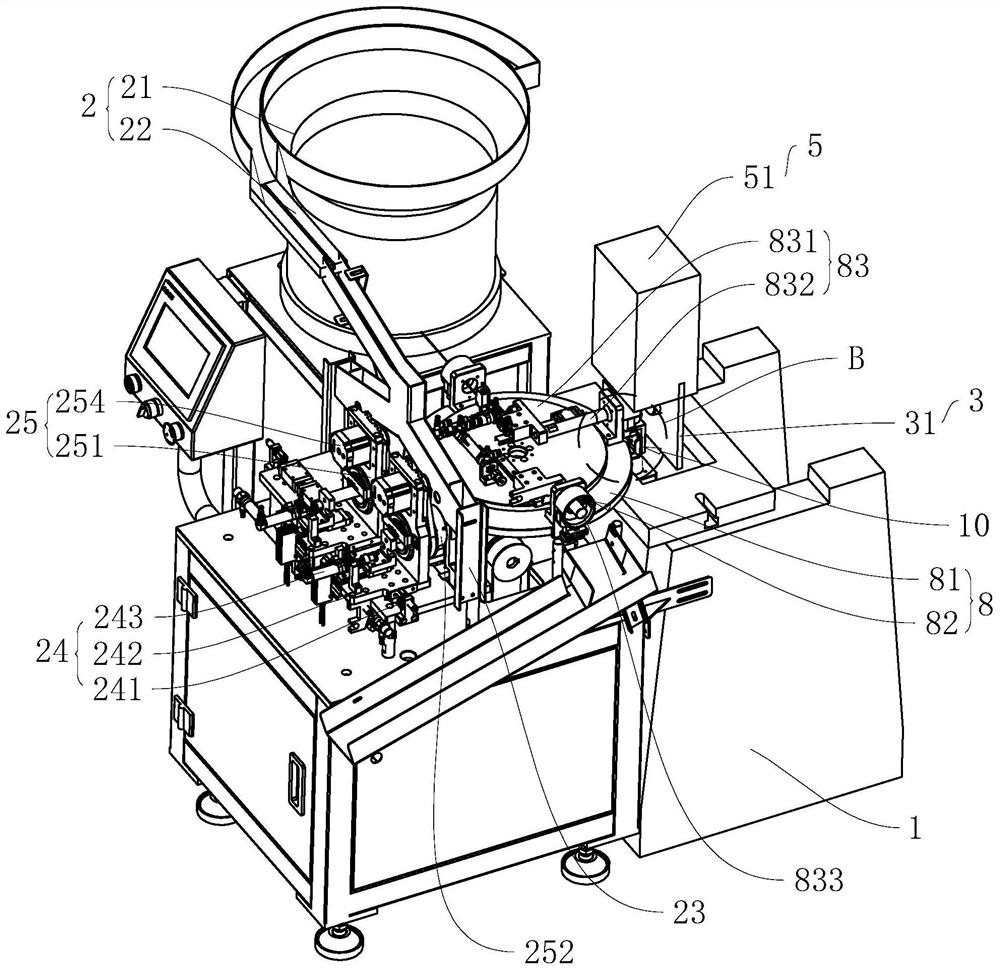

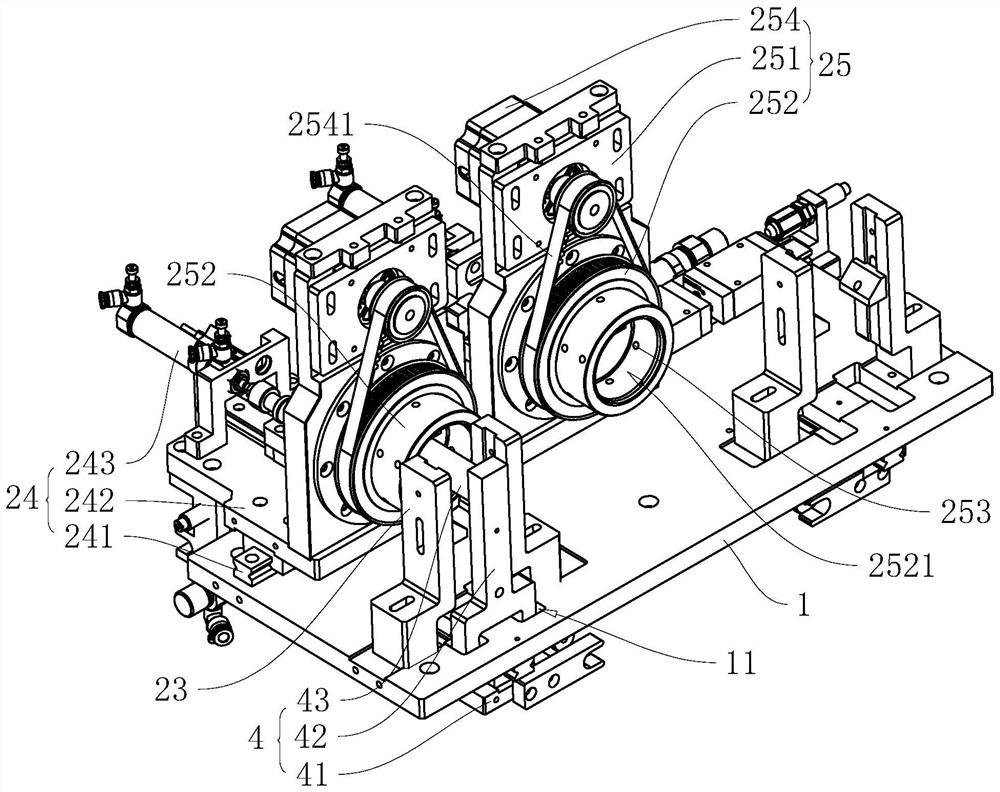

[0040] The embodiment of the present application discloses a dotting machine, referring to figure 1 , including a body 1, a feeding mechanism 2, and a dotting mechanism 3, and the body 1 is used as a supporting body for feeding the feeding mechanism 2, the dotting mechanism 3, and the like. The feeding mechanism 2 includes a vibrating plate 21, a blanking slideway 22, a receiving tray 23, a pushing assembly 24, and an adjustment assembly 25. The vibrating plate 21 is a spiral vibrating feeder 41, and its principle is to transfer the parts to the The edge of the disk body, and make the parts rotate under the action of the vibration wave, so as to realize the feeding process of the parts falling from the disk body one by one; It is inclined downward to form a slideway for the material to slide down on the vibrating plate 21.

[0041] The end of the blanking chute 22 away from the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com