Coupling welding equipment and method for coaxial collimator

A welding equipment and collimator technology, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of unsuitable coupling and packaging of coaxial collimators, and achieves improved convenience and coupling accuracy. The effect of enhancing convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

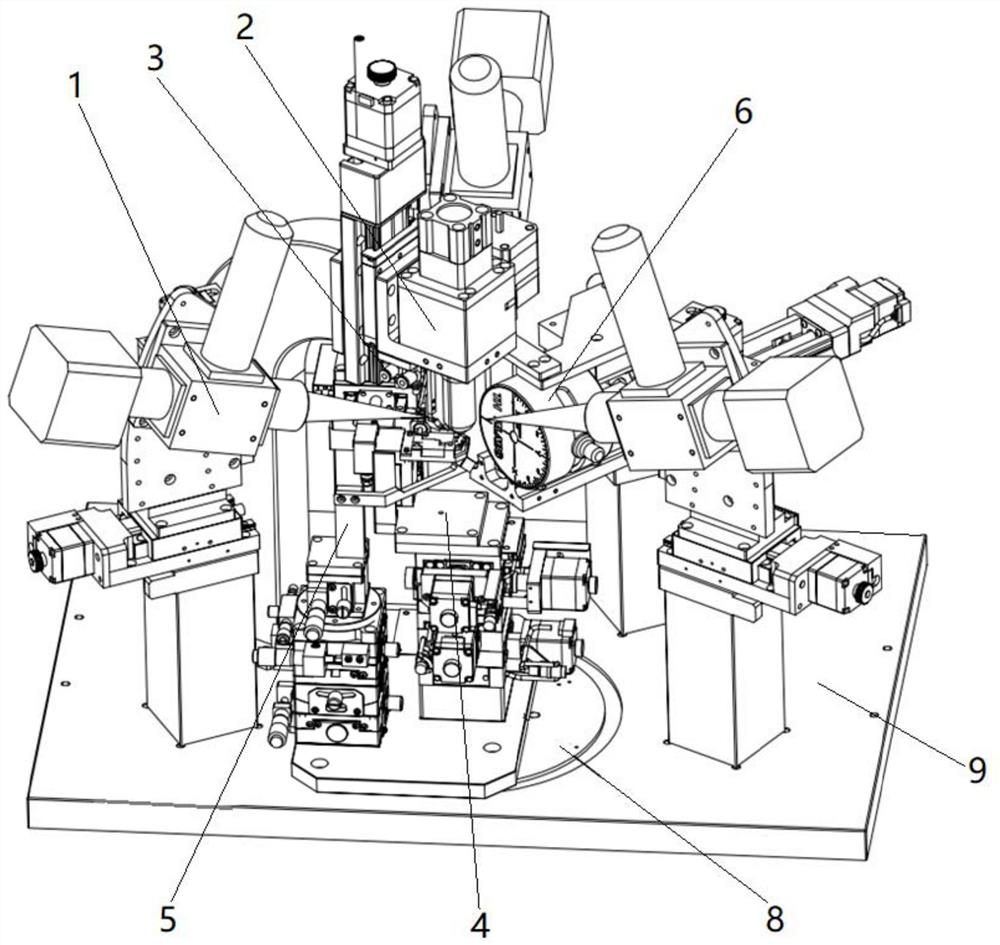

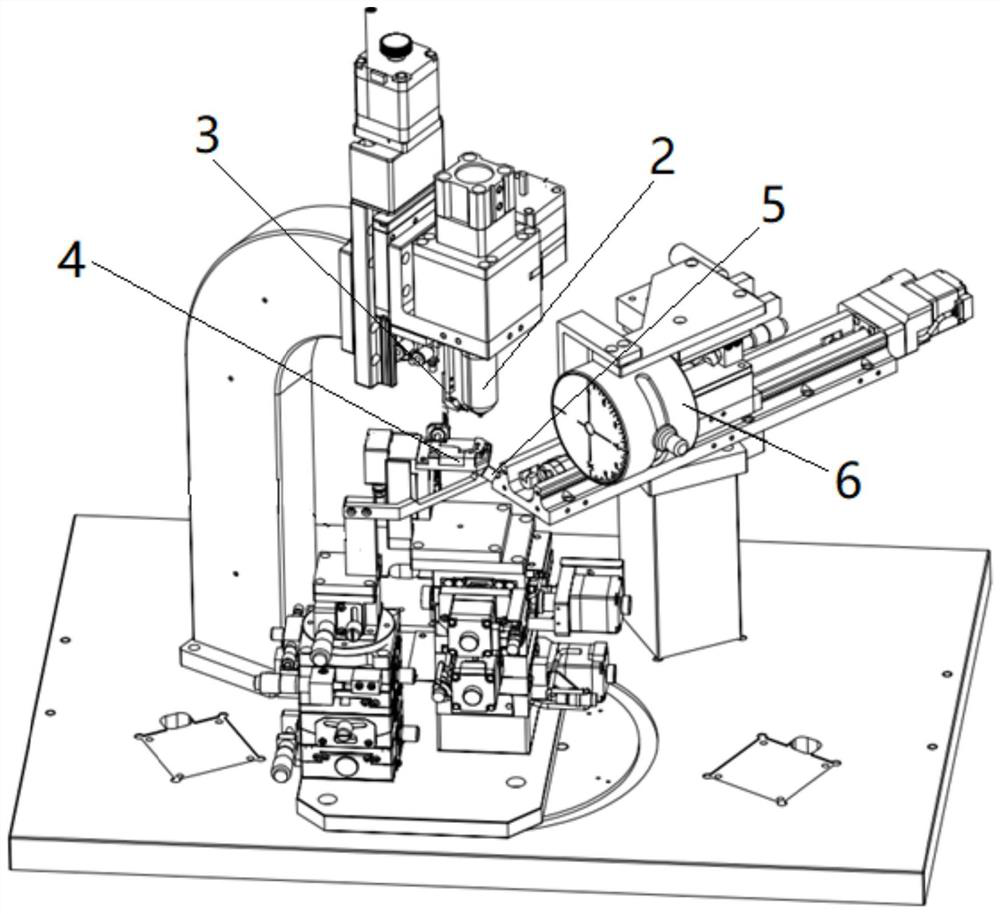

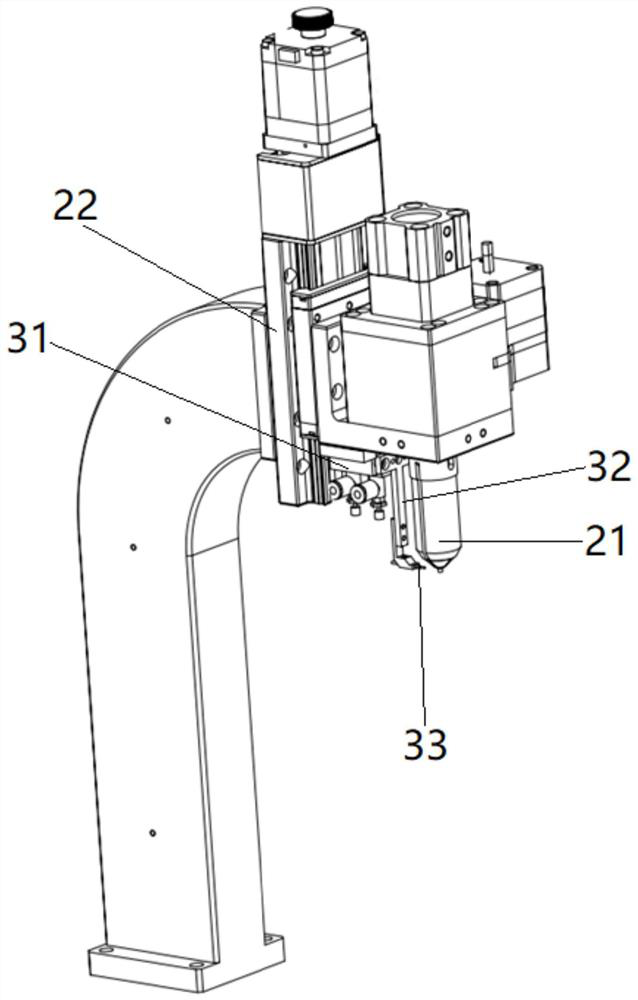

[0040] Such as figure 1 , figure 2 and Figure 8 As shown, Embodiment 1 of the present invention provides a coupling welding device for a coaxial collimator, including a laser welding torch assembly 1, an upper clamp assembly 2, an adjustment ring tightening assembly 3, a lens clamp assembly 4, and a mirror assembly 5 and detection analysis component 6. Among them, the upper clamp assembly 2 clamps and positions the optical fiber adapter 71, the lens clamp assembly 4 clamps and positions the lens 72, and the optical fiber adapter 71 is pre-set with an adjustment ring 73, and the adjustment ring 73 is tightened on the optical fiber adapter by the adjustment ring tightening assembly 3 71, the reflector assembly 5 has multiple degrees of freedom of movement. The reflector 51 is moved and positioned under the lens 72, so that the outgoing light energy of the lens 72 can be reflected to the detection and analysis assembly 6, so that the light spot can be detected by the detectio...

Embodiment 2

[0052] Embodiment 2 of the present invention provides a coupling welding method of a coaxial collimator, specifically comprising the following steps:

[0053] Step 1, feeding, the upper clamp assembly 2 clamps the optical fiber adapter 71 , the adjusting ring 73 is pre-sleeved on the optical fiber adapter 71 , the adjusting ring clamping assembly 3 clamps the adjusting ring 73 tightly, and the lens clamping assembly 4 clamps the lens 72 .

[0054] Step 2, the upper fixture assembly 2 is lowered to the coupling position, and the near-field light spot is initially coupled, and the size of the light spot is adjusted to an appropriate position by adjusting the Z-axis position, and the distance coupling between the optical fiber adapter 71 and the lens 72 is confirmed, and the outgoing light of the lens 72 is parallel light (Gaussian beam), adjust the X-axis and Y-axis positions of the beam profiler 61 through the two-axis displacement slide table 62, so that the spot moves to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com