Support unit

A support device, flange technology, applied in the direction of transportation and packaging, brakes, brake components, etc., can solve problems such as high complexity and heavy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

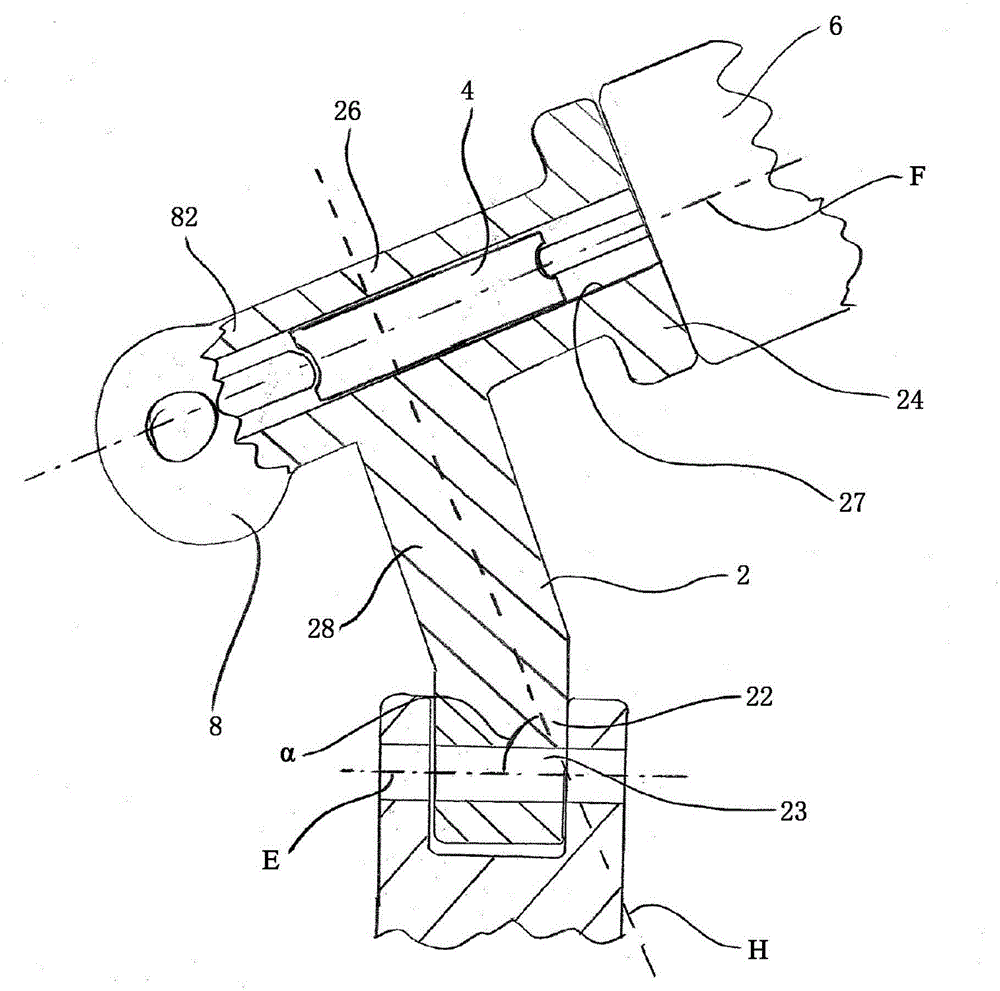

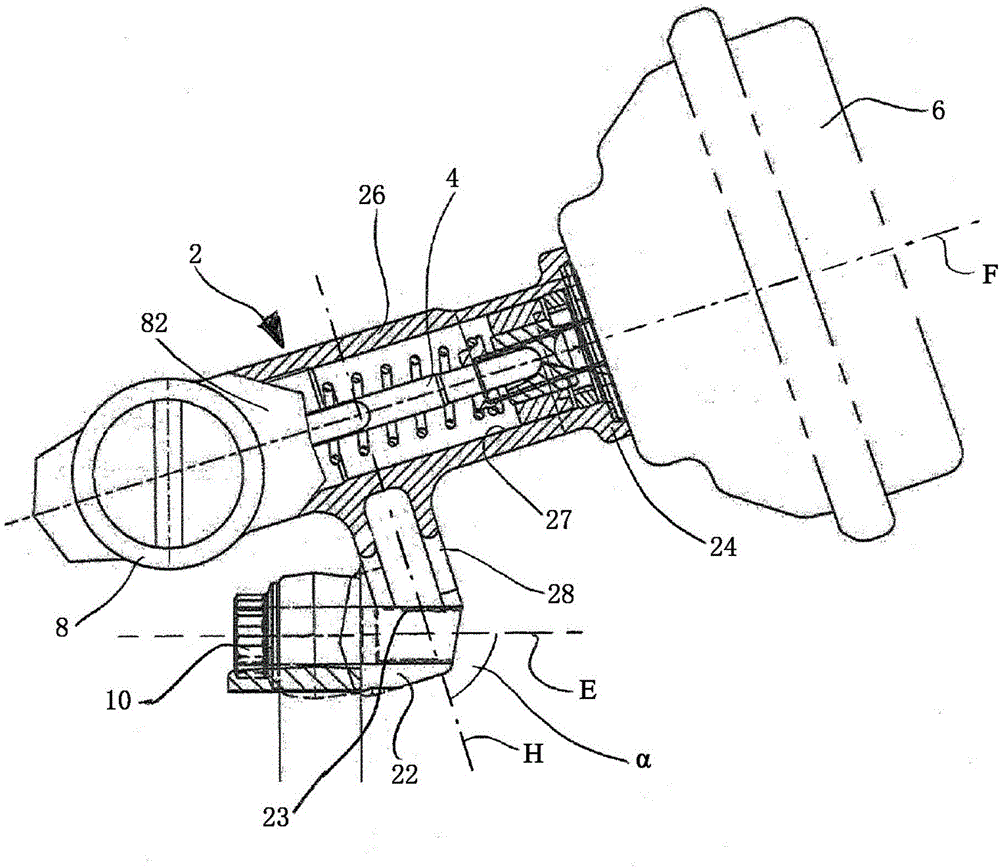

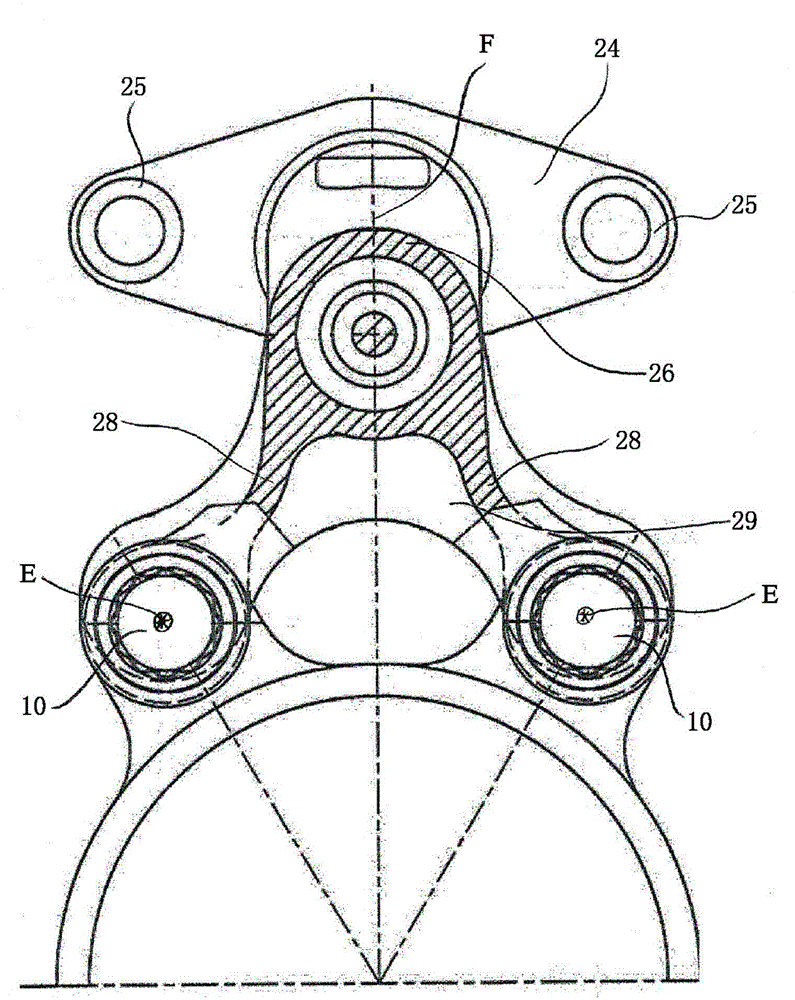

[0024] exist figure 1 In the shown schematically simplified sectional view of a preferred embodiment of the support device 2 according to the invention, the expansion wedge device 8 with the housing 82 is only partly sectioned, and the other parts not sectioned are in a very simplified manner. icon. The support device has a guide 26 adjacent to the housing 82 of the expansion wedge device 8 , in which the guide element 4 is arranged so as to be displaceable and guided along the guide axis F. As shown in FIG. In this case, the guide part 26 in particular has a guide geometry 27 which is constructed in a particularly preferred manner as a cylindrical hollow space inside the guide part 26 and which ensures that the guide element 4 does not vertically displacement on the guide axis F and facilitates the sliding of the guide element 4 . Opposite the expansion wedge device 8 , the support device 2 has a second flange part 24 to which the brake cylinder 6 can be fastened or prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com