Rotating disc type automatic processing machine

An automatic processing, turntable technology, used in metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of low production efficiency and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

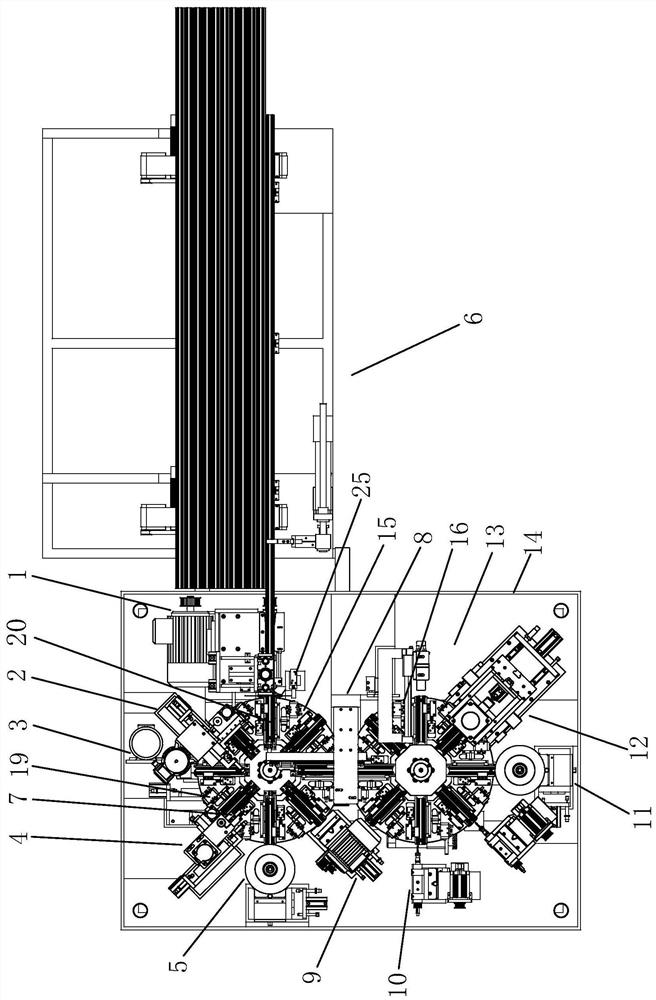

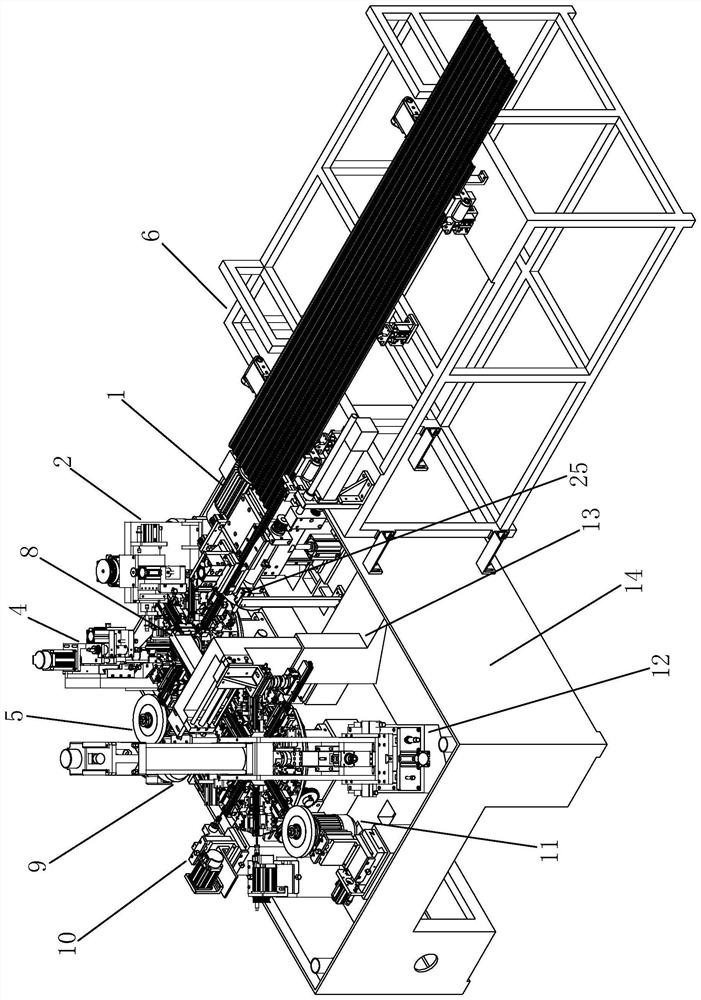

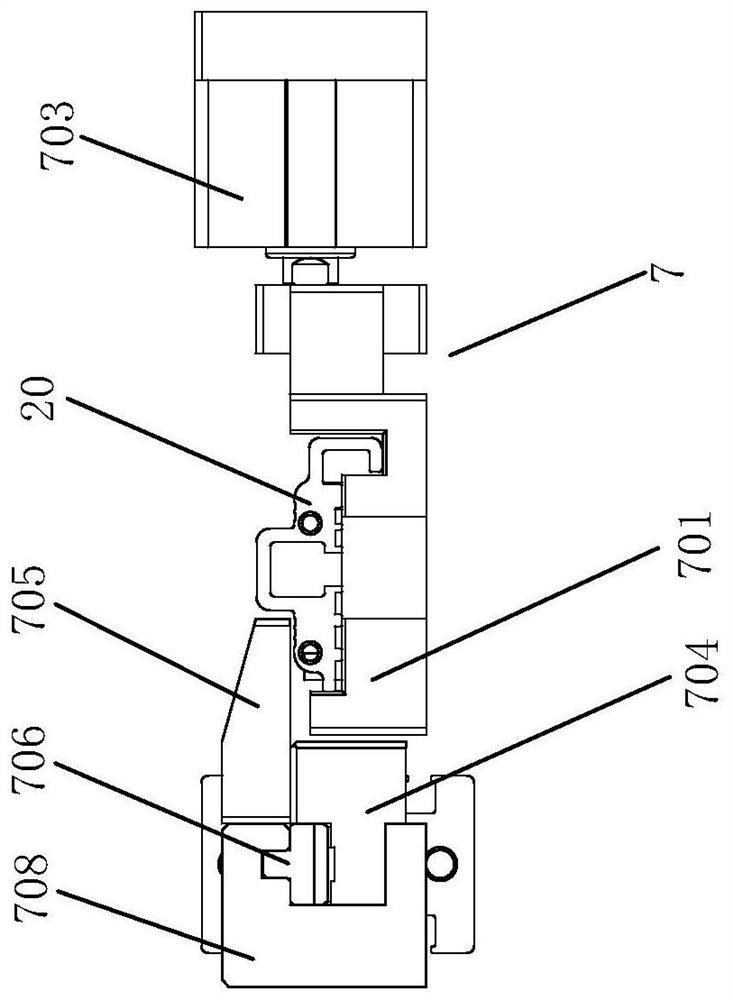

[0057] The present invention will be further described below in conjunction with the accompanying drawings.

[0058] Such as figure 1 , figure 2 A rotary table type automatic processing machine shown includes a frame one 14 and a PLC control unit, a rotary table one 15 and a rotary table two 16 are arranged side by side on the frame one 14, and a divider one is respectively arranged under the rotary table one 15 and the two rotary table 16 And divider two, divider one and divider two can make turntable one 15 and turntable two 16 rotate fixed angle each time, and turntable one 15 and turntable two 16 are evenly provided with fixture one 7 in the circumferential direction, and fixture one 7 is used To fix and clamp the profile 20, it is convenient for the processing mechanism to process the profile 20. One side of the fixture 7 is provided with a mechanical valve 19 for controlling the opening or clamping of the fixture 7. Each fixture 7 is correspondingly provided with a mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com