A wire harness guide support wire groove and its production process

A technology of supporting wires and supporting parts, which is applied in the direction of thin material processing, coating, pretreatment surface, etc., can solve the problems of easy deflection and vibration of cables, and achieve the effect of ensuring the stability of transportation, improving the stability of transportation and light texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

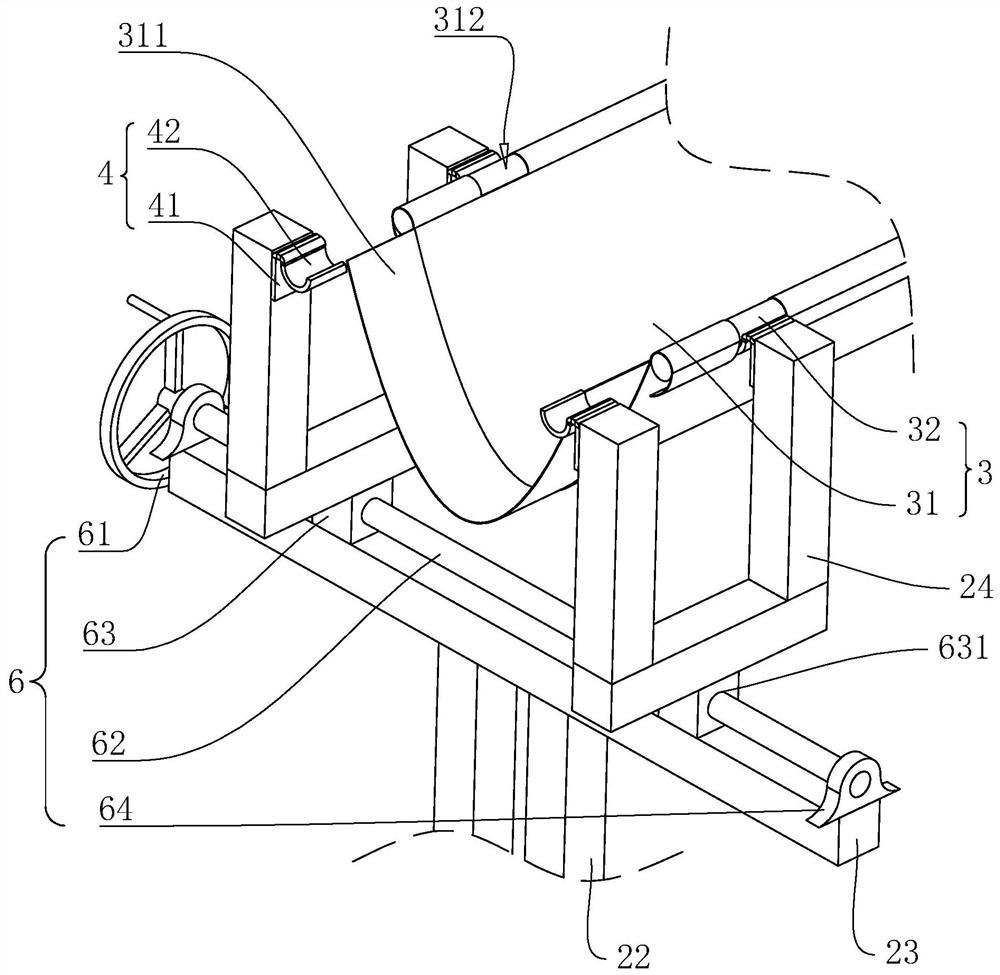

[0039] Attached to the following Figure 1-4 This application will be described in further detail.

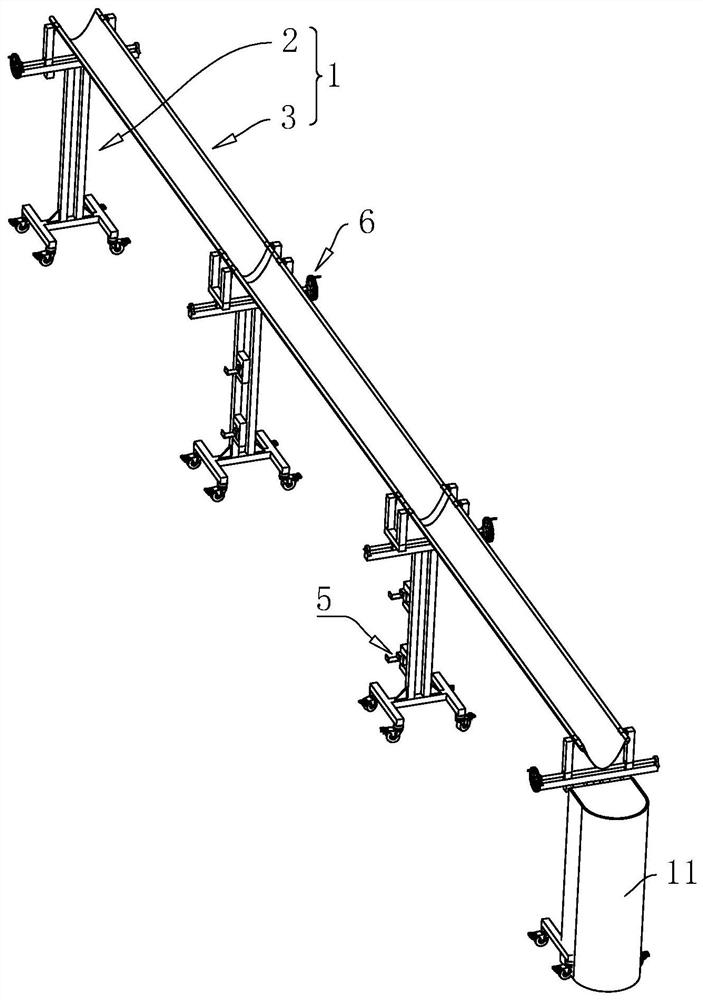

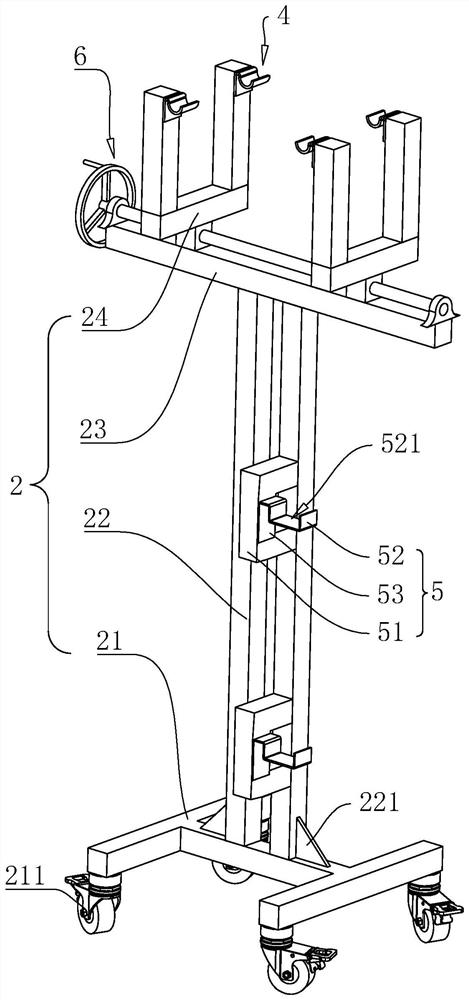

[0040] The embodiment of the present application discloses a wire harness guiding and supporting wire groove. refer to figure 1 , a wire harness guiding and supporting wire groove includes a receiving wire pocket 11 and a plurality of conveying racks 1 . In this embodiment, the storage wire pocket 11 may be a box body with a cover made of soft glass, and the inner cavity of the storage wire pocket 11 is used to store cables. The conveyor 1 is used to support and guide the cables to be transmitted, so as to ensure the stability and convenience of the cable processing equipment when processing the cables.

[0041] refer to figure 1 , the adjacent conveyor racks 1 are symmetrical with each other and the lengthwise ends are abutted, so that all the conveyor racks 1 are in a collinear state to ensure the stability of cable transportation. At the same time, the operator can incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com